Chemical Industry

Chemical Industry

Solutions for the chemical

industry

Demanding processes require robust and reliable equipment. Our end-of-line solutions for the chemical industry ensure control, traceability, and regulatory compliance.

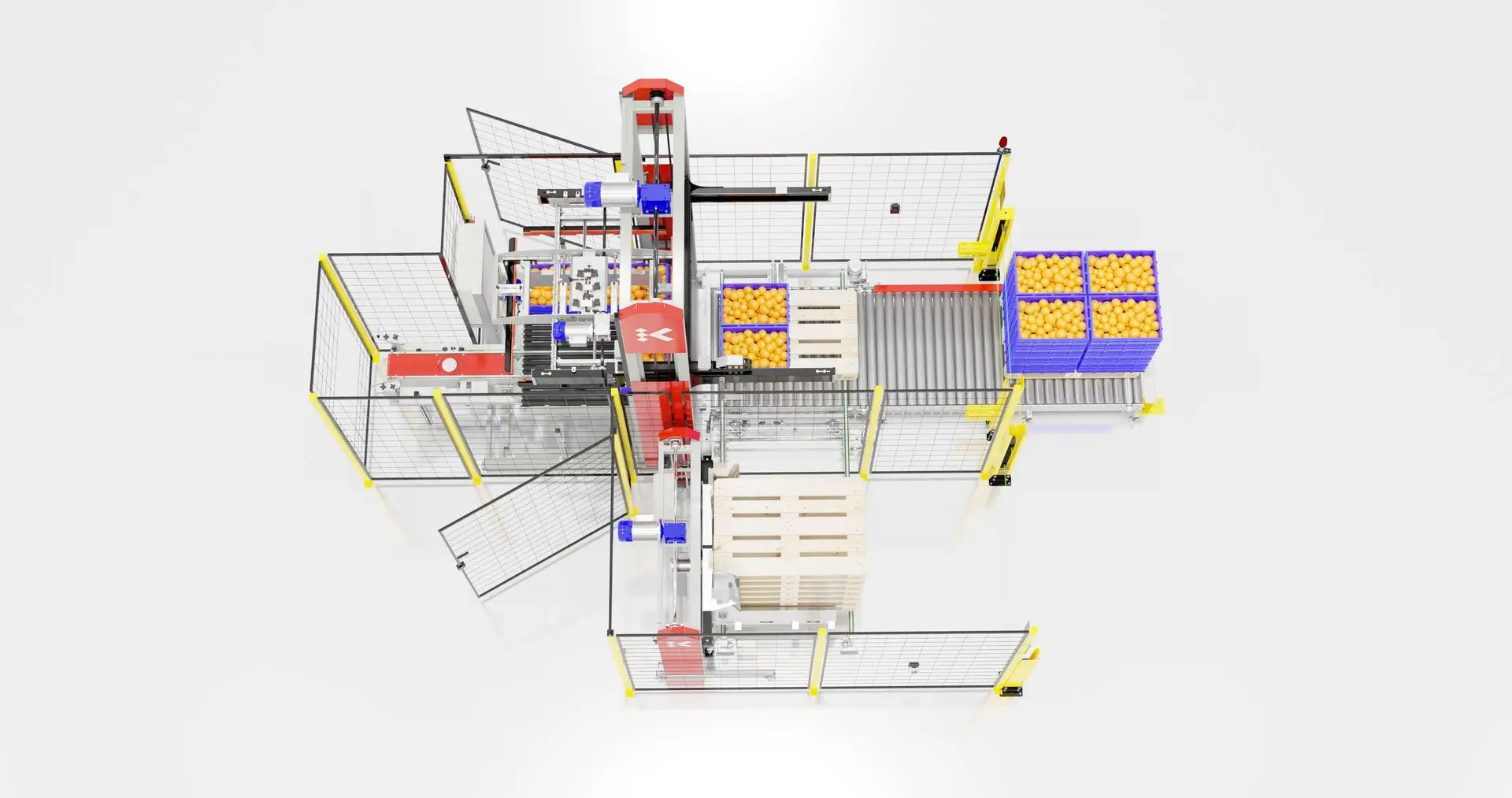

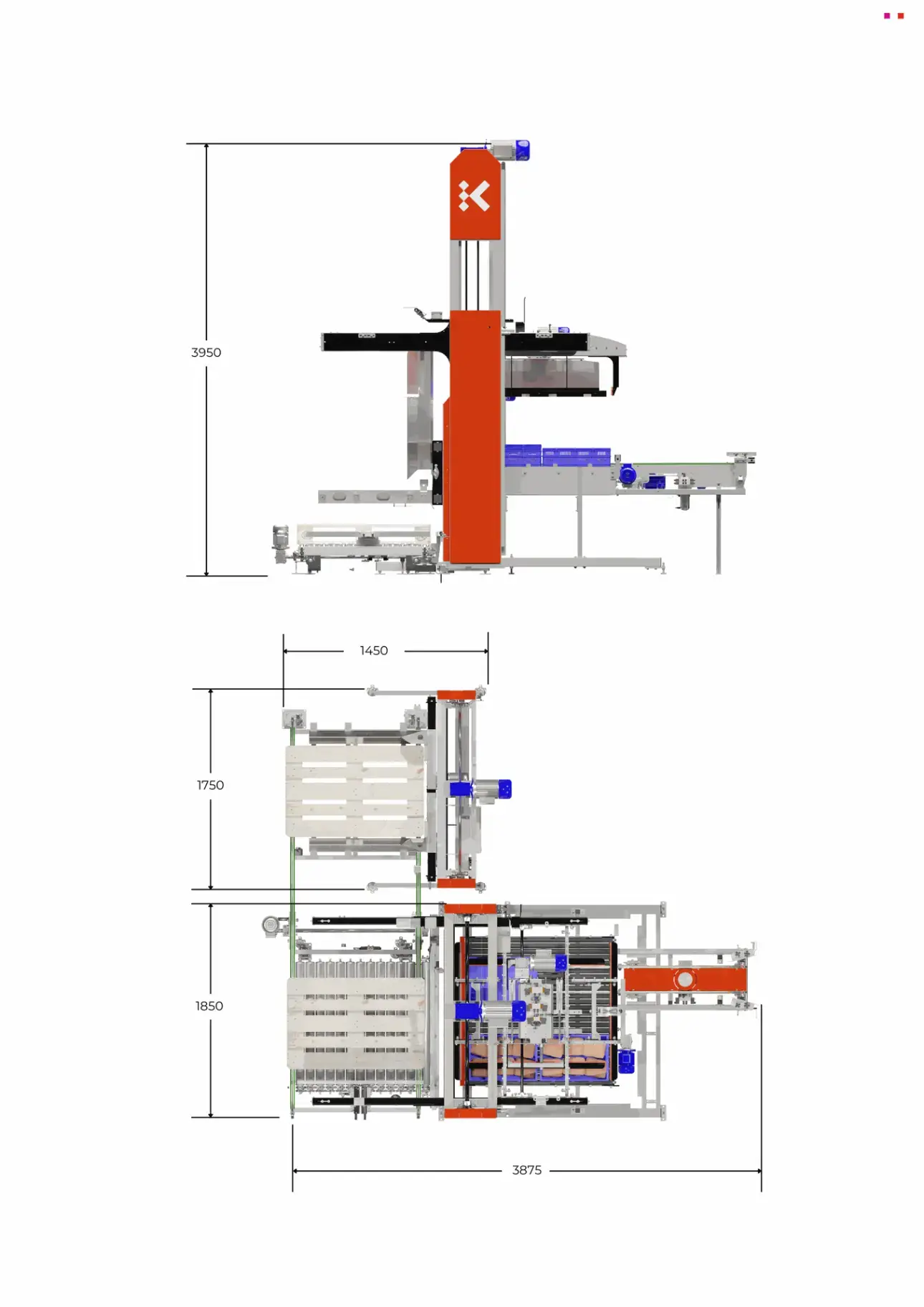

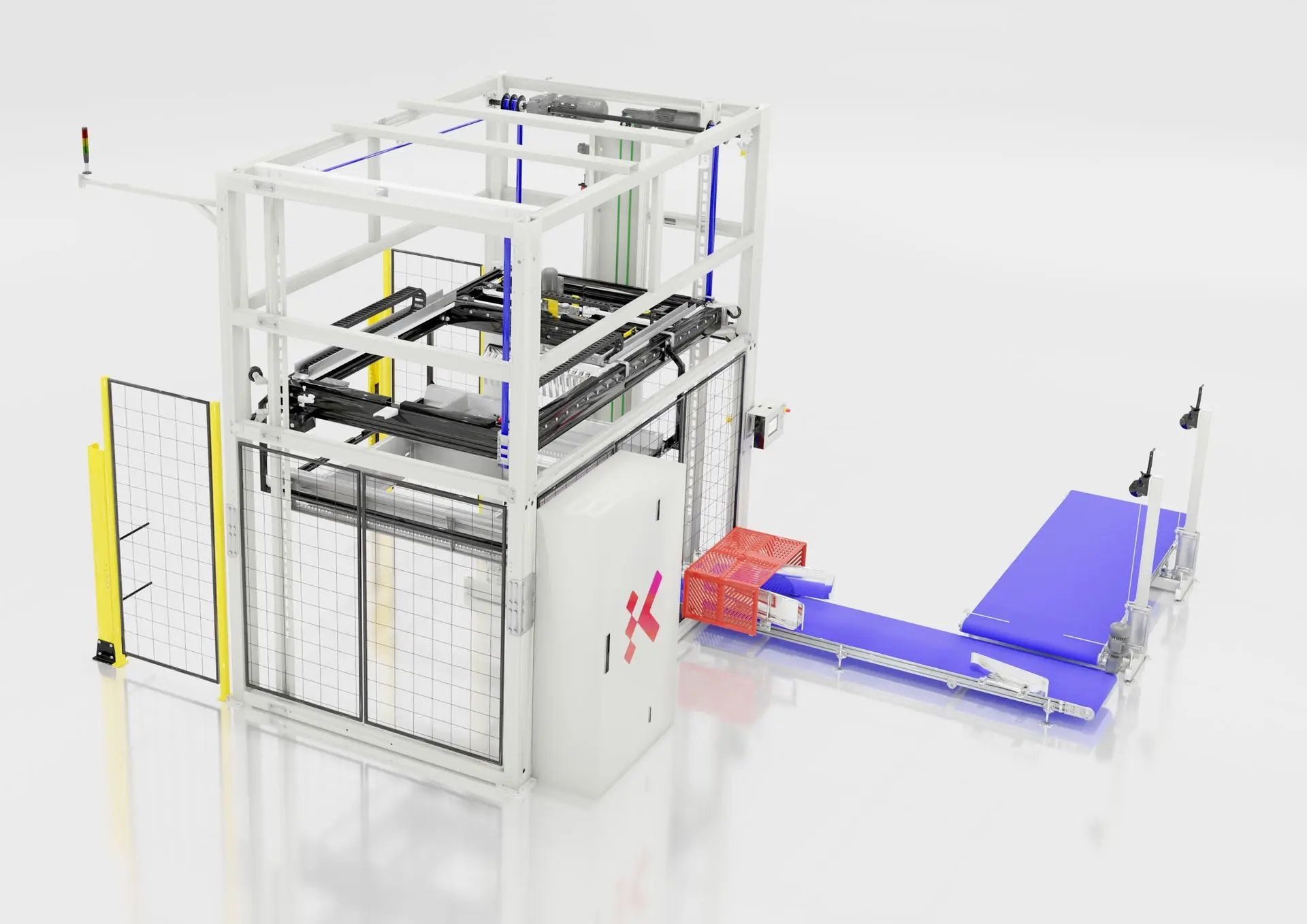

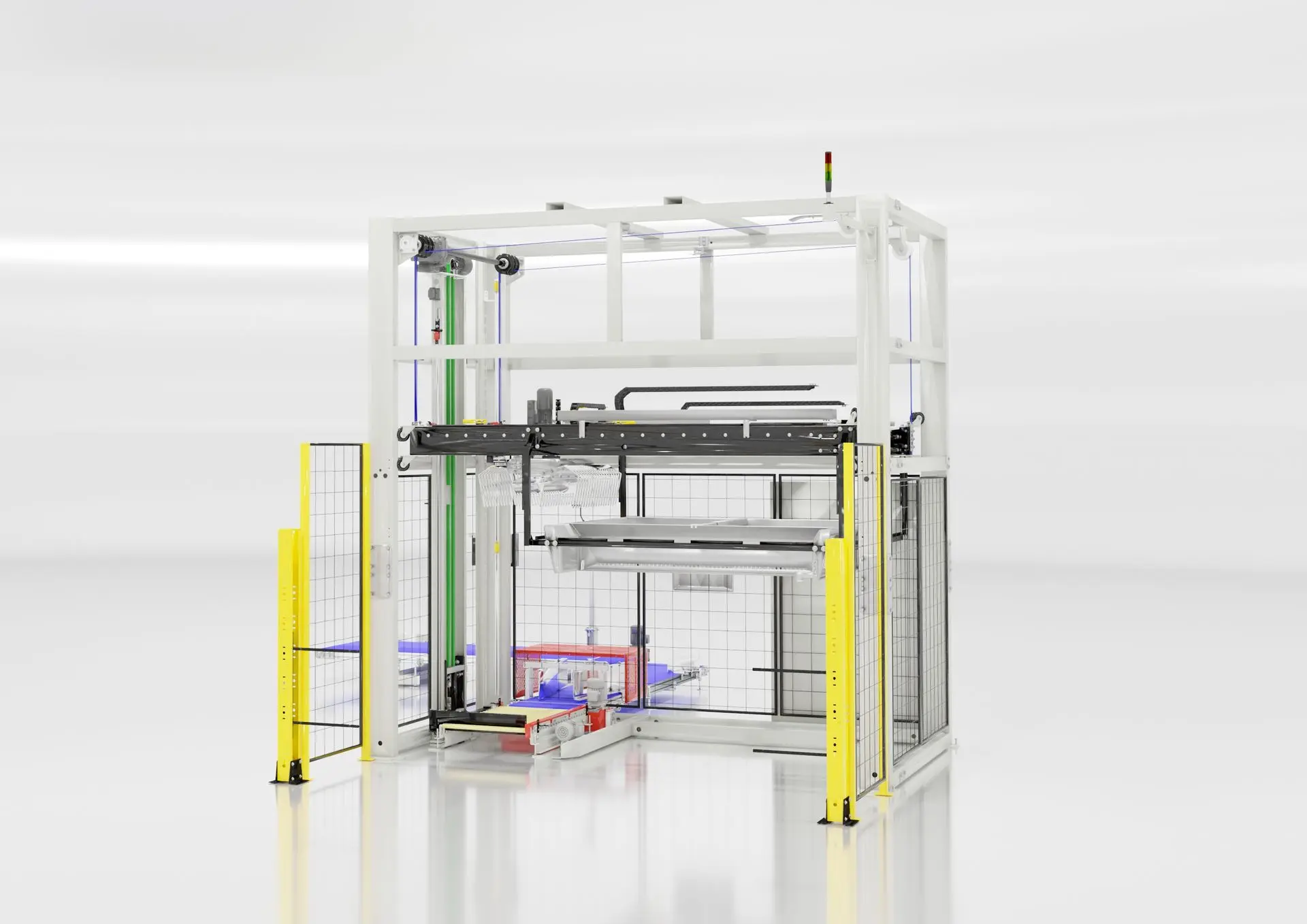

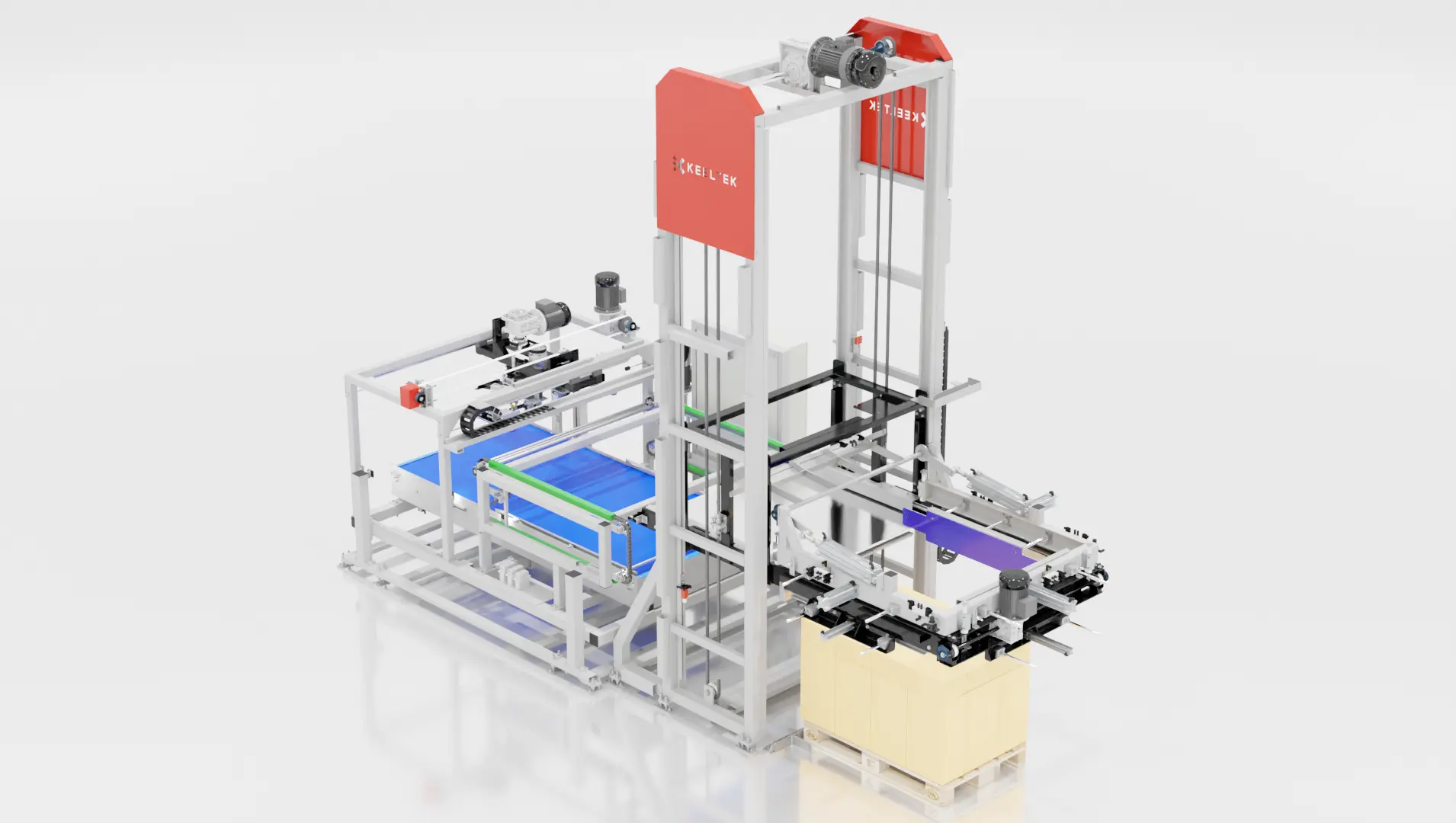

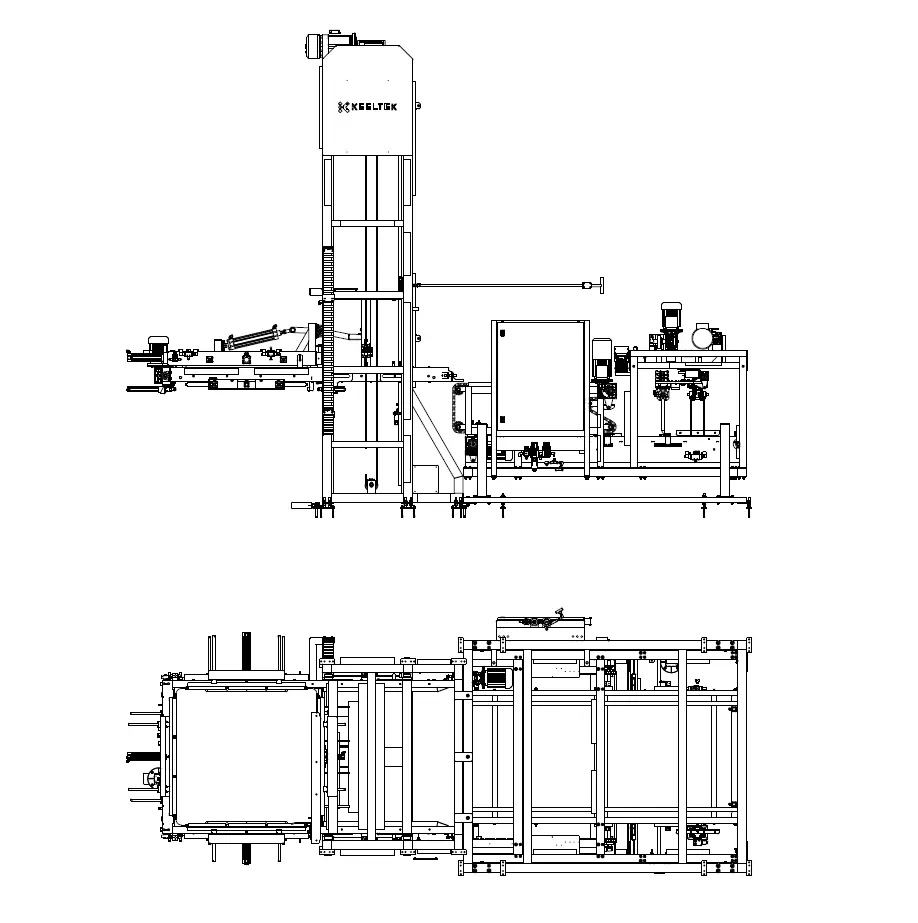

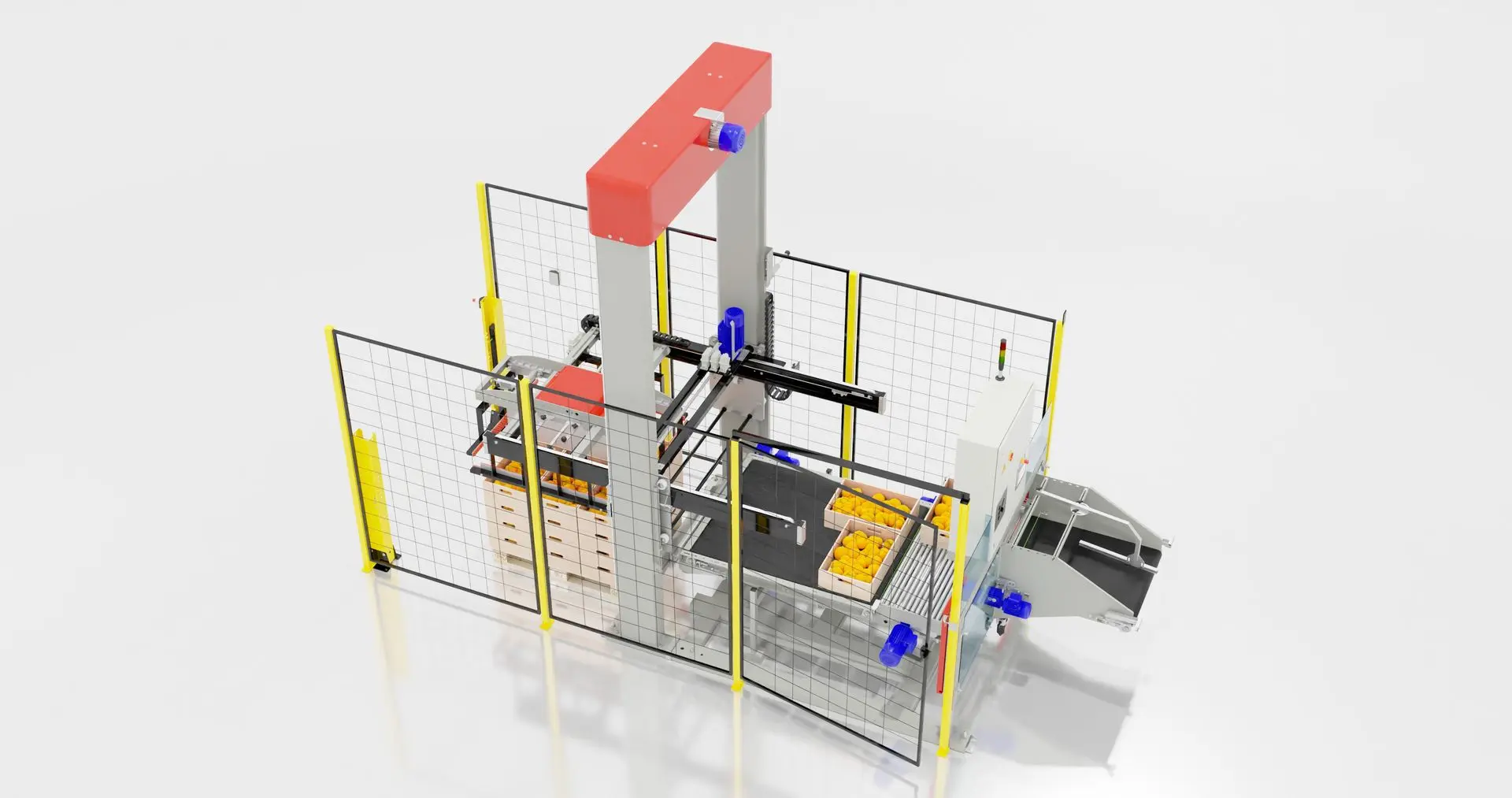

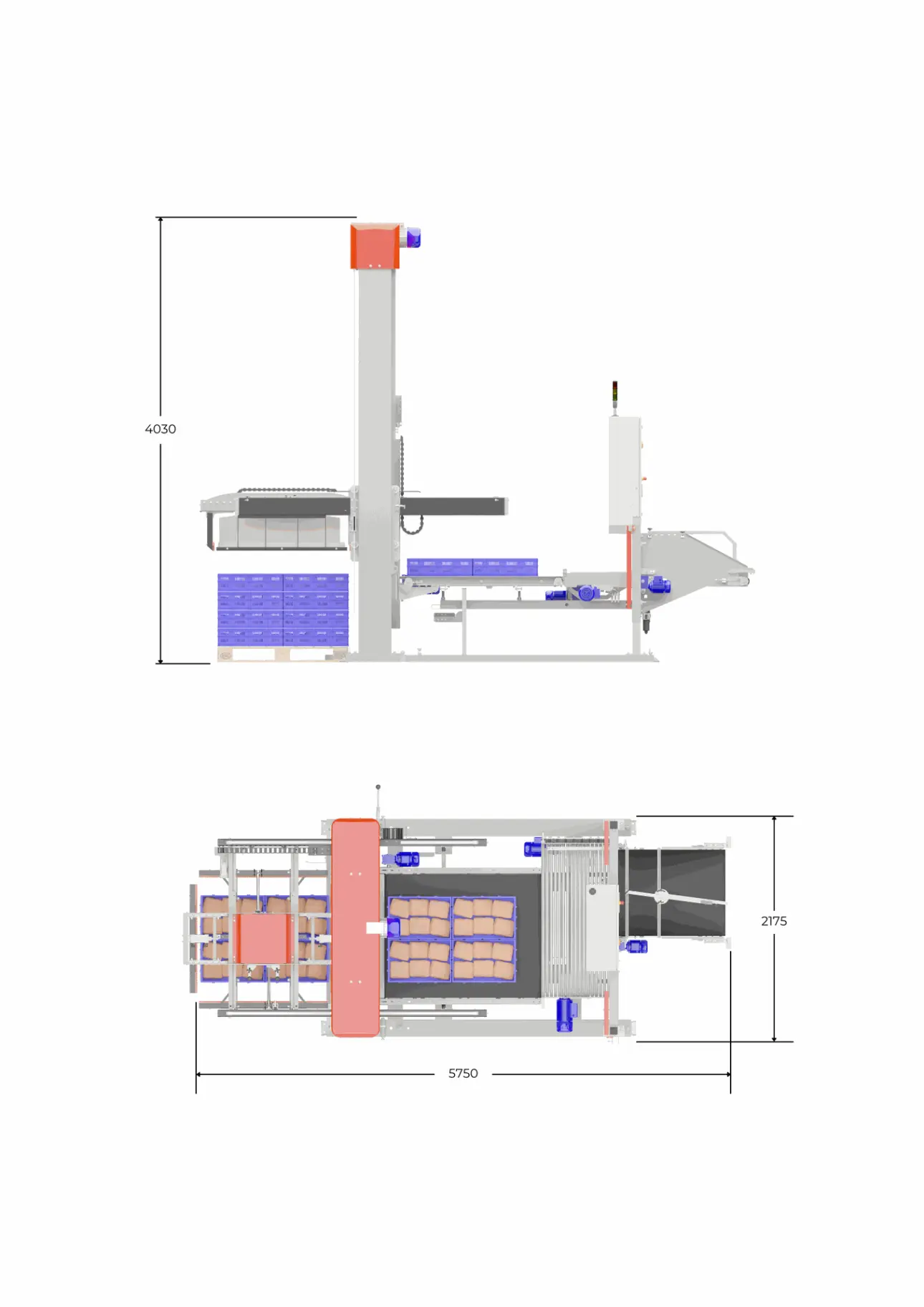

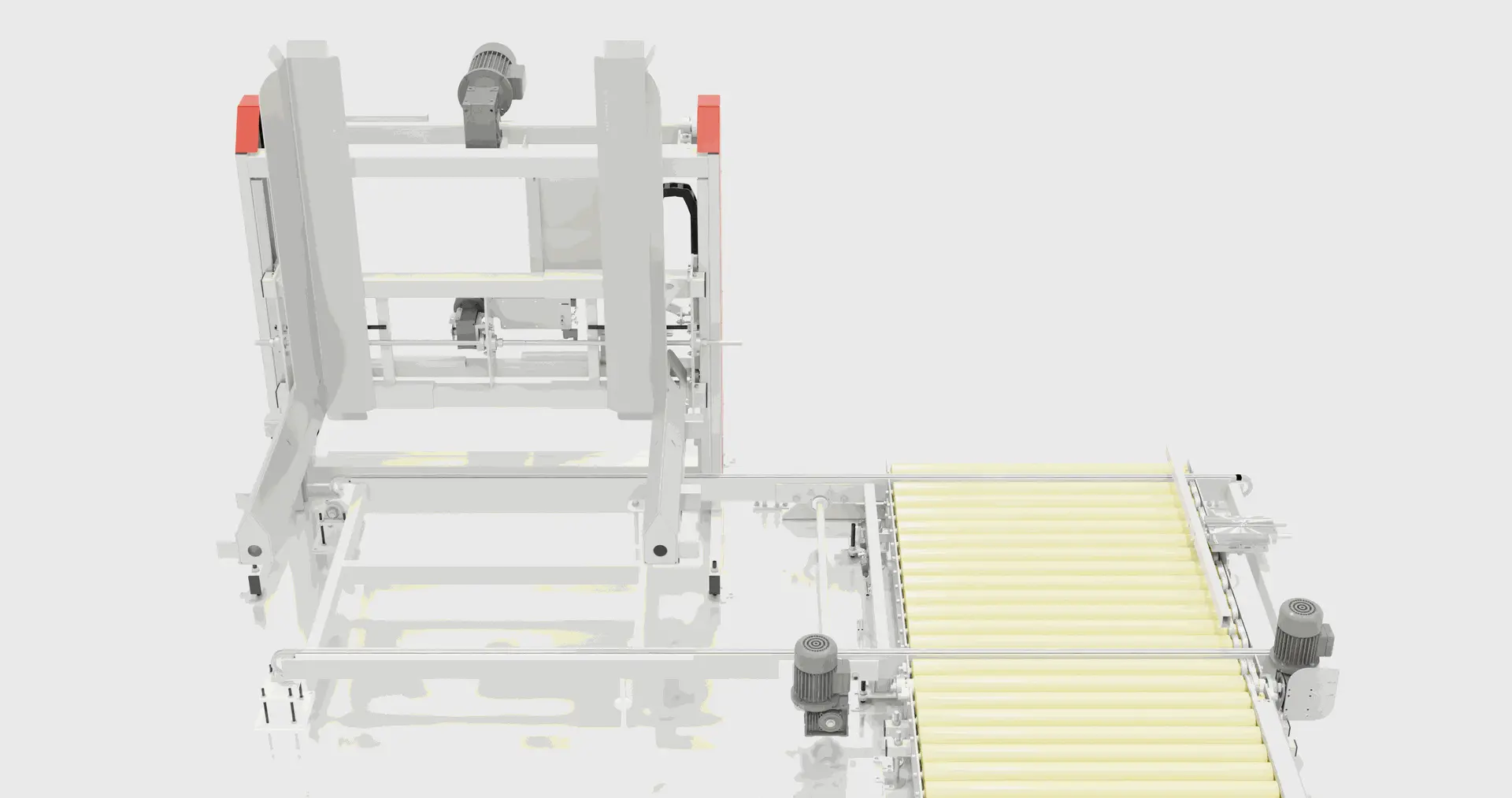

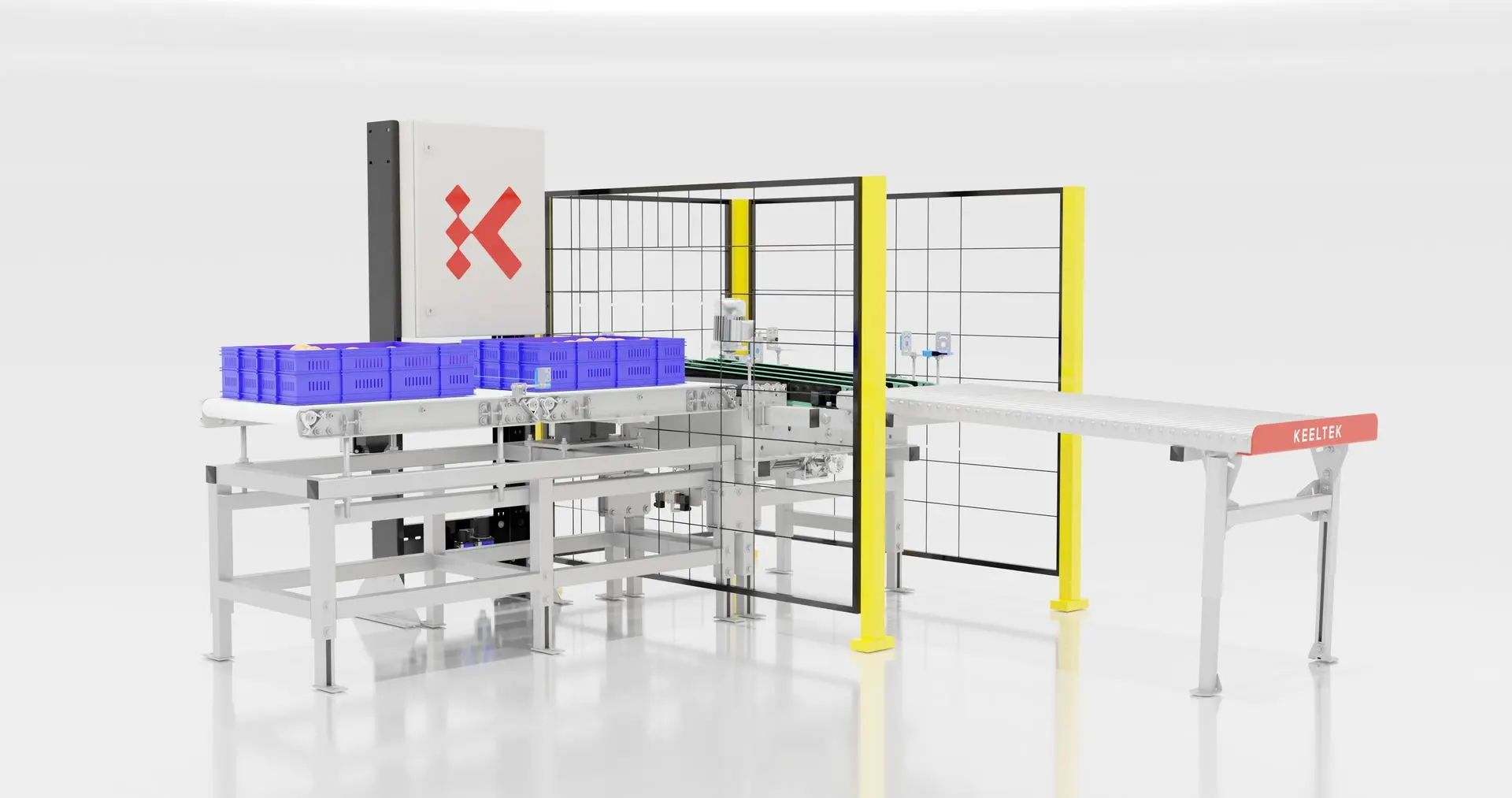

EASYPAL / EASYDEPAL

2-axis Cartesian palletizer by layers

2-axis Cartesian palletizer/depalletizer with combined chain and roller table, with box gripping system using a clamp equipped with 2 or 4 jaws, designed for palletizing or depalletizing boxes in layers.

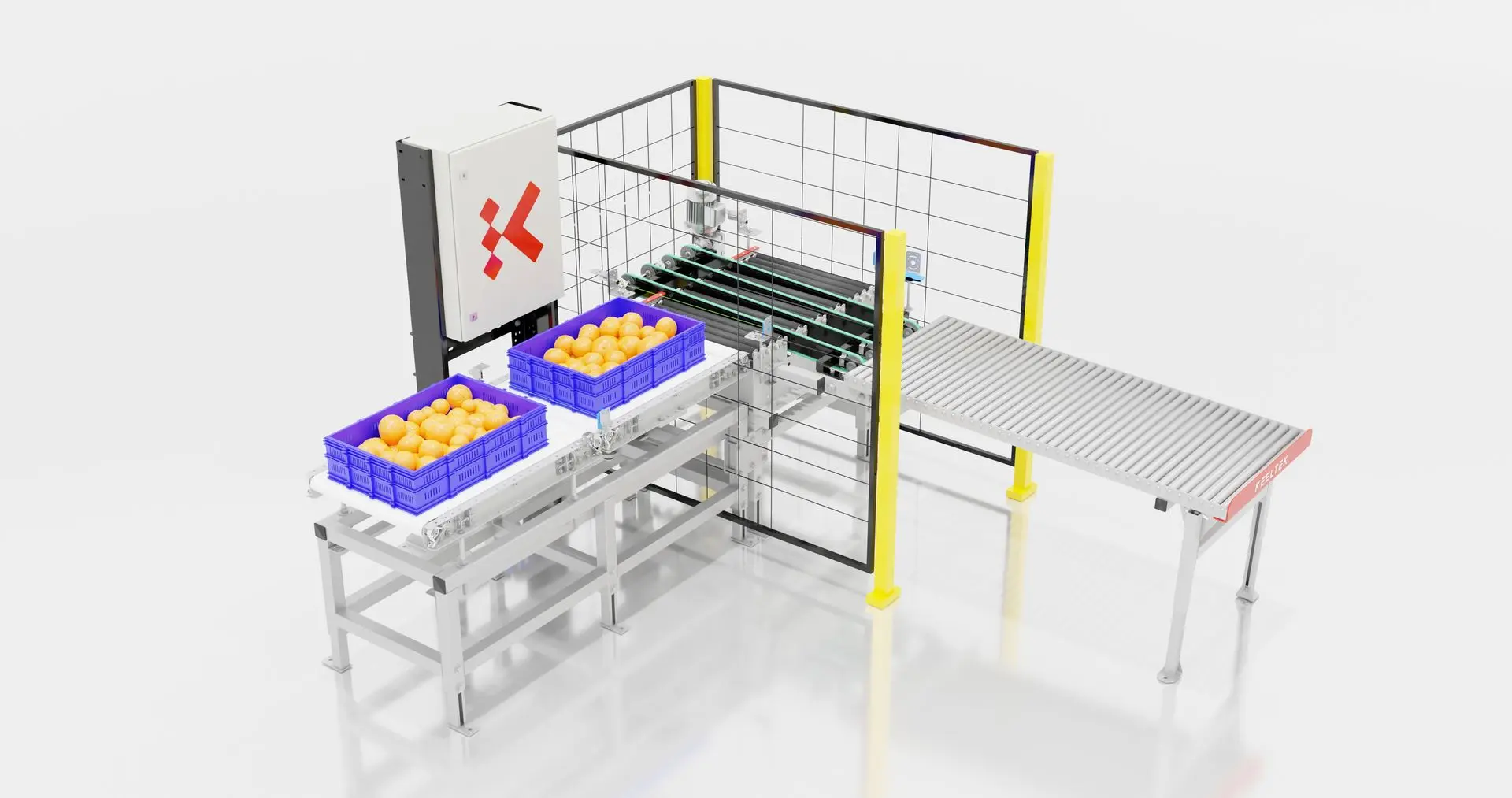

EASYPAL / EASYDEPAL

2-axis Cartesian palletizer by layers

2-axis Cartesian palletizer/depalletizer with combined chain and roller table, with box gripping system using a clamp equipped with 2 or 4 jaws, designed for palletizing or depalletizing boxes in layers.

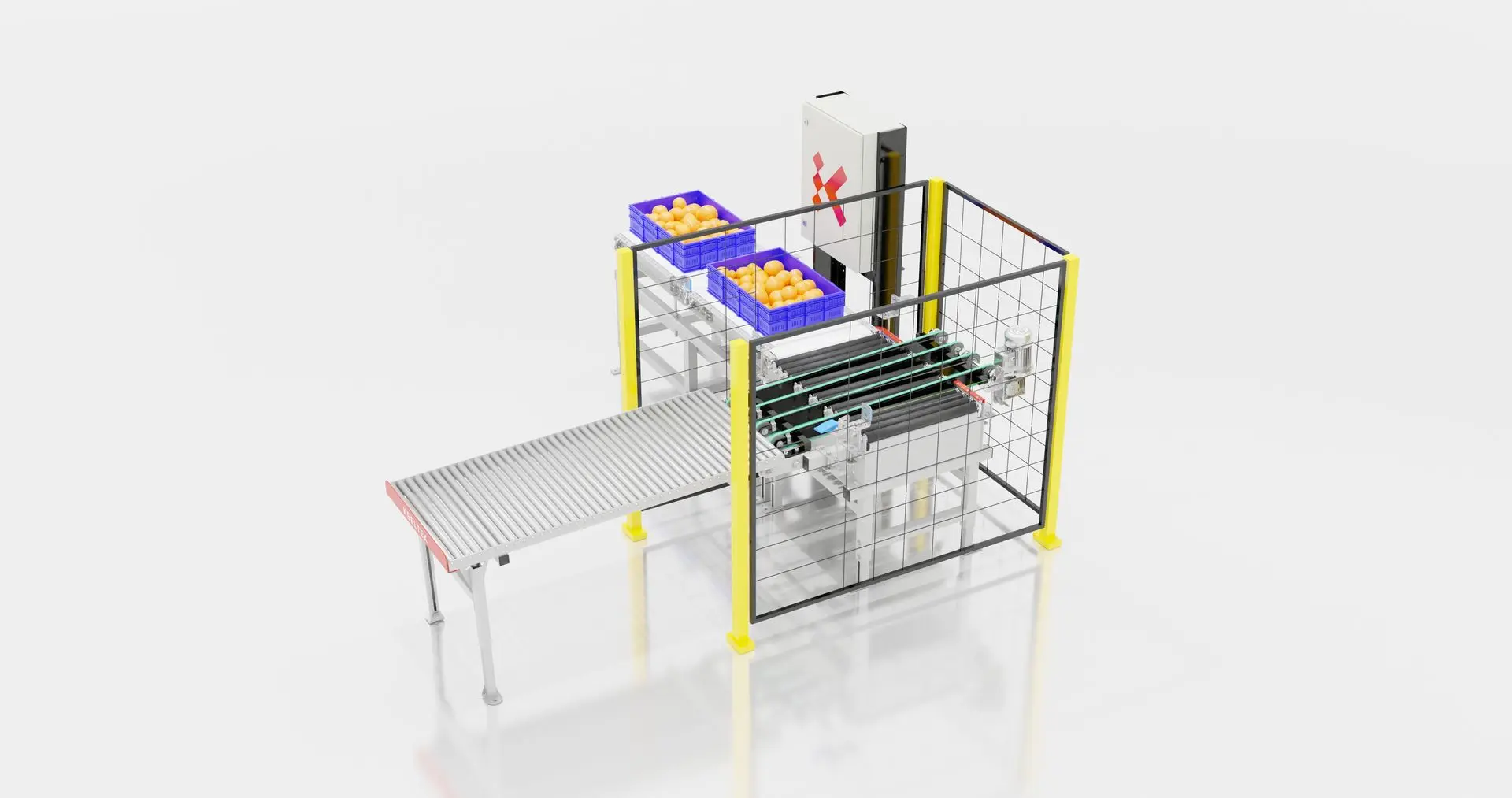

EASYPAL / EASYDEPAL

2-axis Cartesian palletizer by layers

2-axis Cartesian palletizer/depalletizer with combined chain and roller table, with box gripping system using a clamp equipped with 2 or 4 jaws, designed for palletizing or depalletizing boxes in layers.

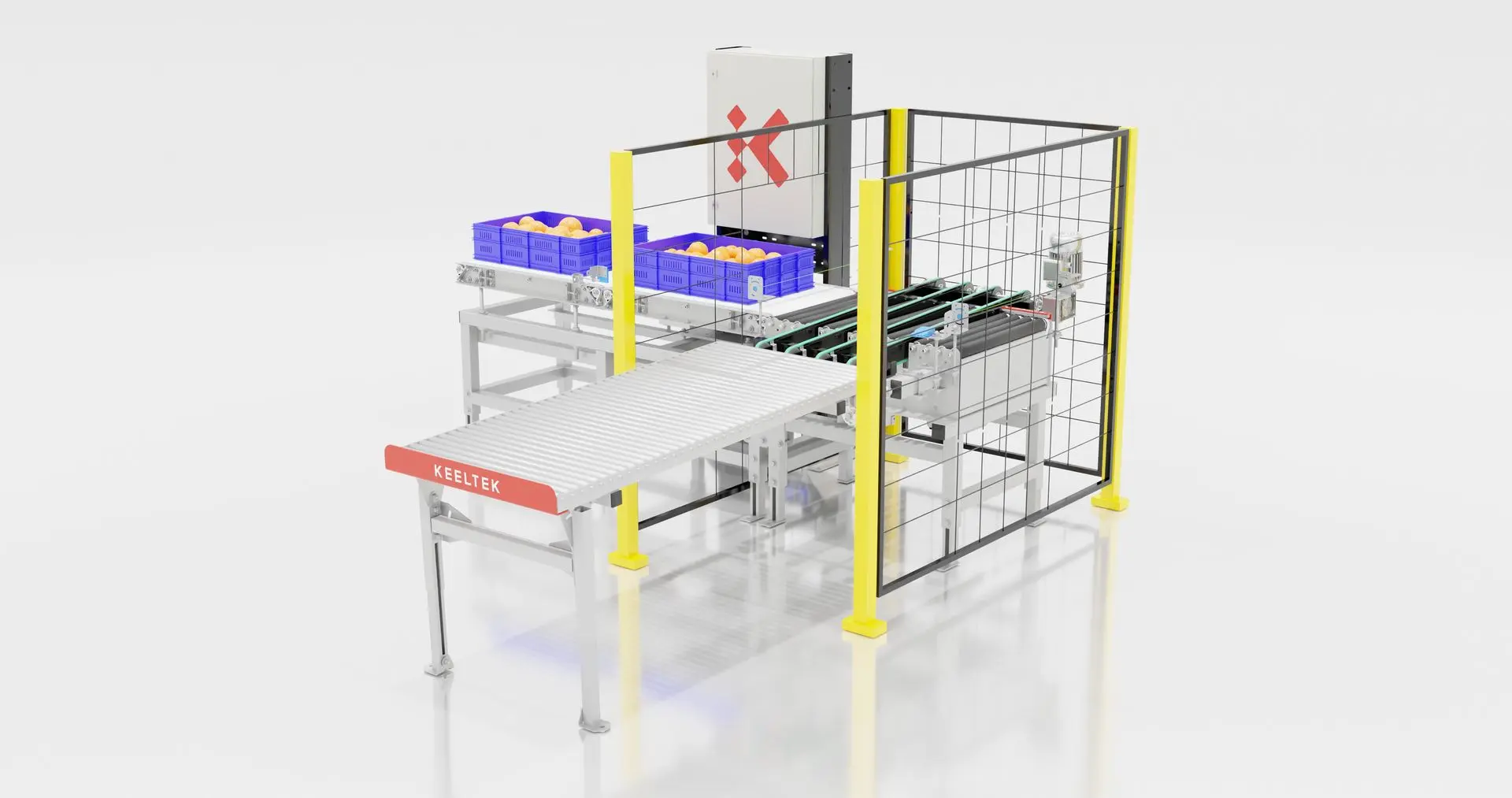

EASYPAL / EASYDEPAL

2-axis Cartesian palletizer by layers

2-axis Cartesian palletizer/depalletizer with combined chain and roller table, with box gripping system using a clamp equipped with 2 or 4 jaws, designed for palletizing or depalletizing boxes in layers.

EASYPAL / EASYDEPAL

2-axis Cartesian palletizer by layers

2-axis Cartesian palletizer/depalletizer with combined chain and roller table, with box gripping system using a clamp equipped with 2 or 4 jaws, designed for palletizing or depalletizing boxes in layers.

| Reference product | Boxes of any size compatible with the pallet |

| Tiles | Any tile configuration |

| Maximum permissible load | Up to 175 kg. |

|

Connectivity

|

Industry 4.0 Ready |

| Cadences | Up to 3 shots per minute. |

Equipment | Rotator with selectable label positioning. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Features:

- Simple and intuitive creation of mosaics by the operator using proprietary software.

- Reversed layer function for improved stability.

Safety and ergonomy:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed by laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Labeling machine integration.

- Automatic pallet dispenser and changer.

- Reversed layer function for improved stability.

- Add pallet between layers function. (Manual or automatic).

- KTS, remote assistance.

- Full stainless steel finishes

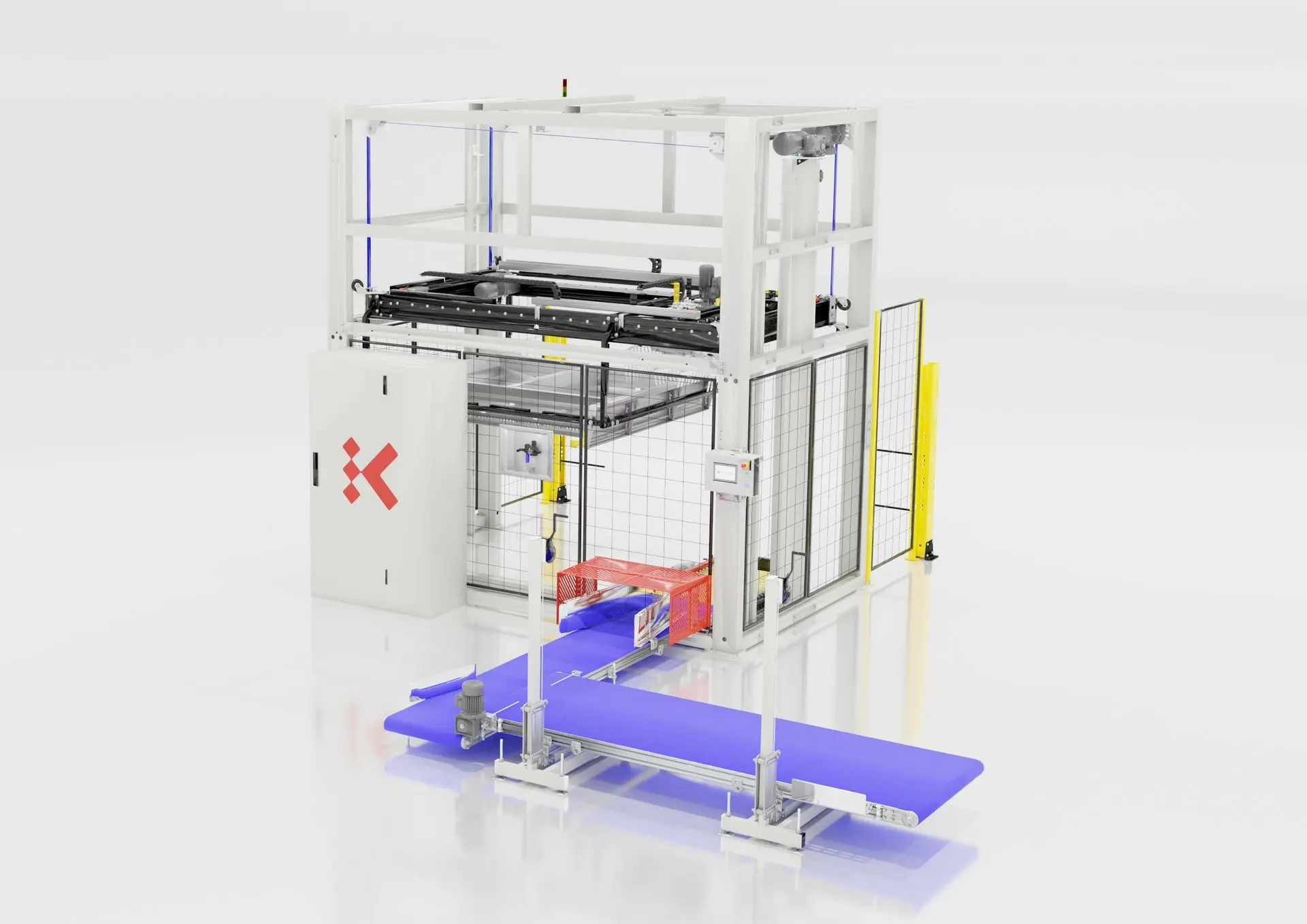

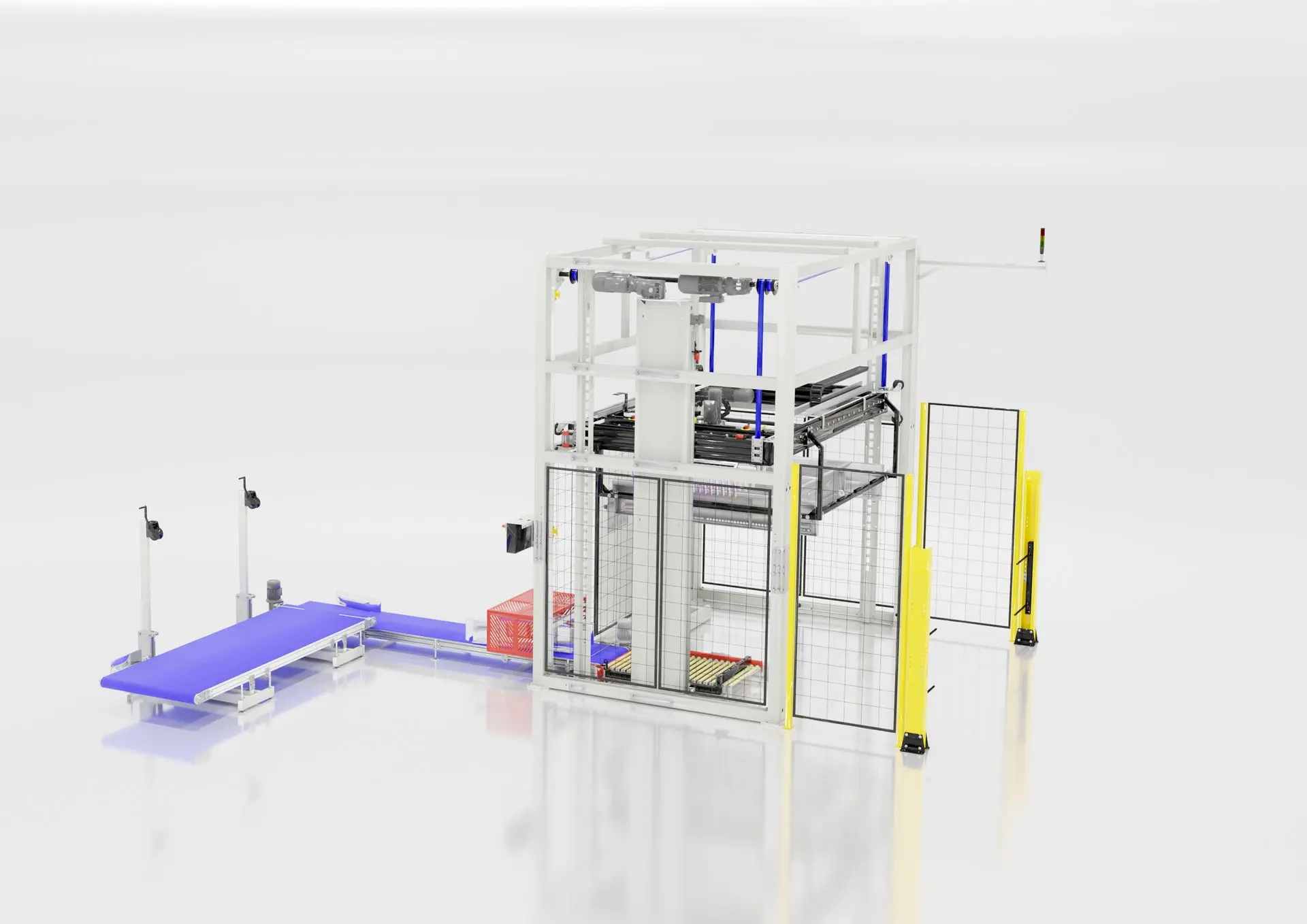

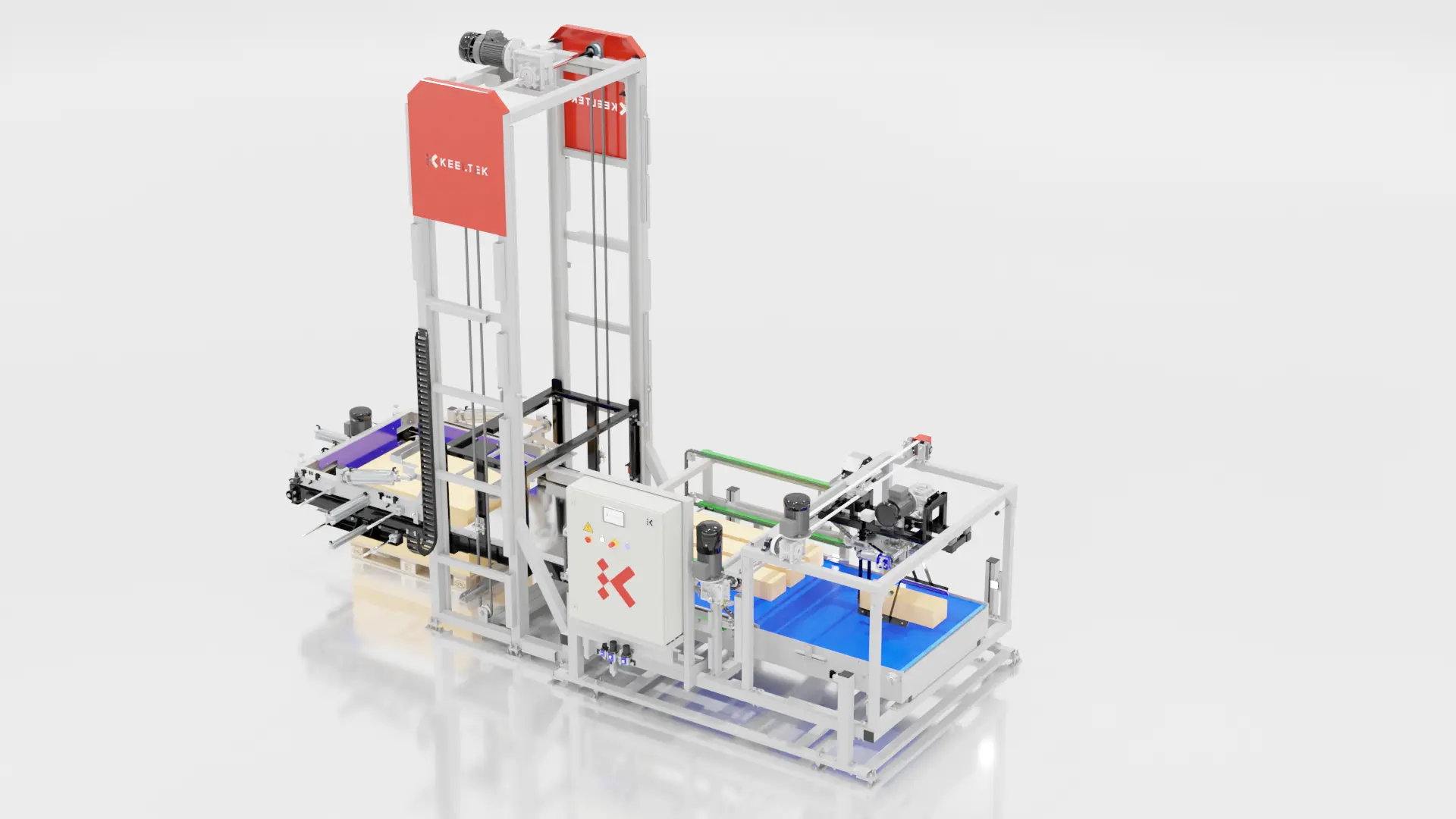

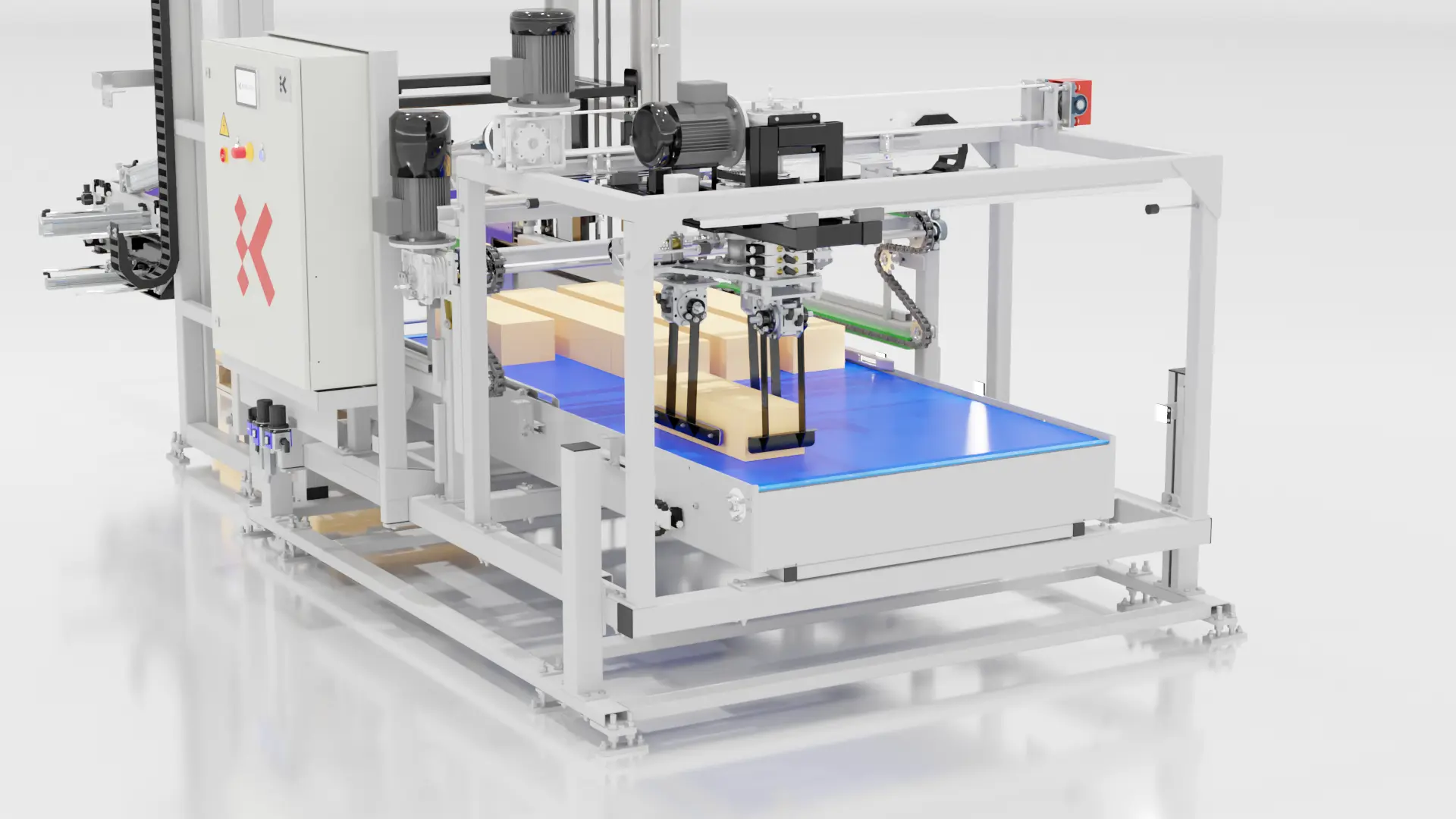

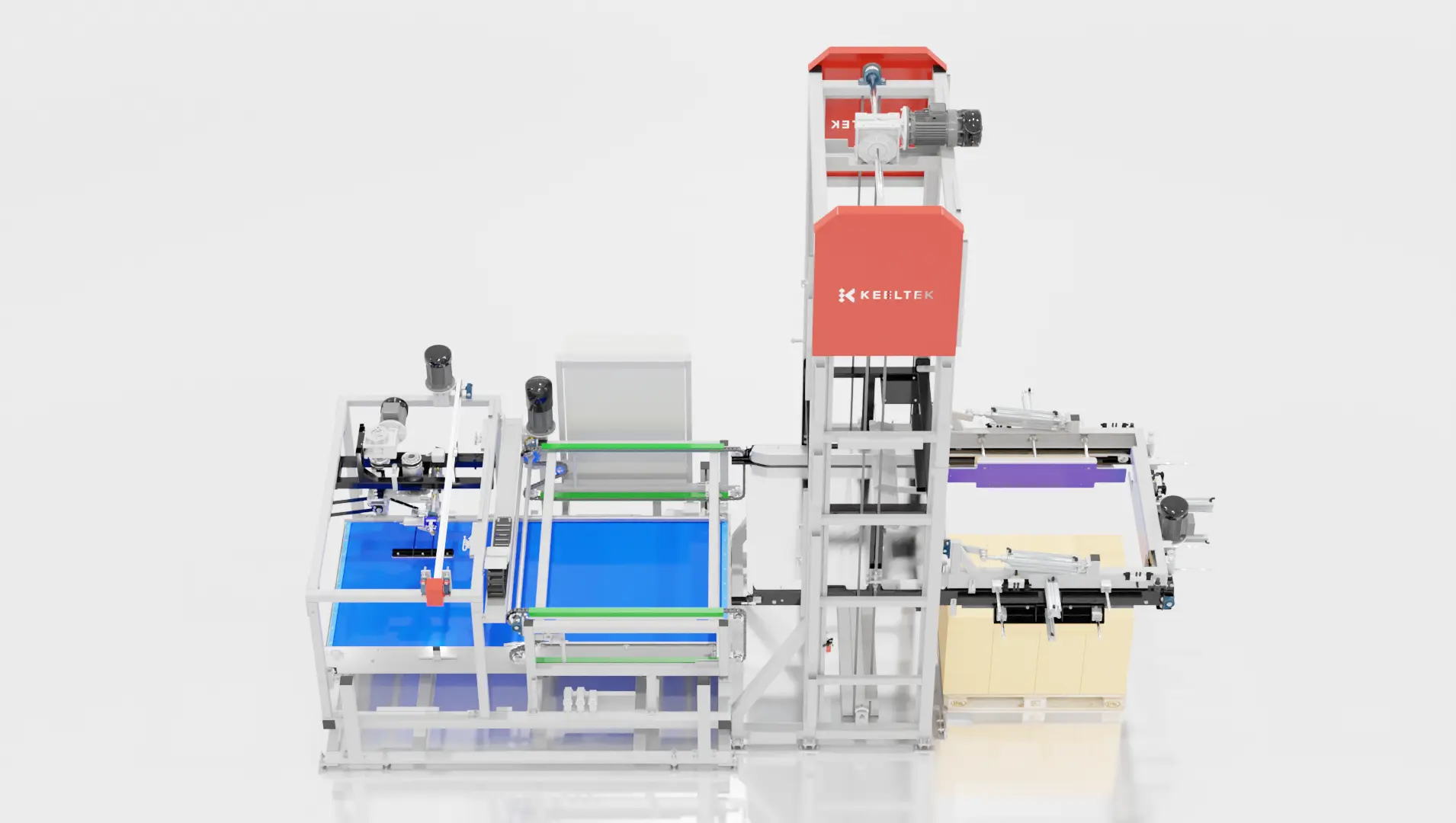

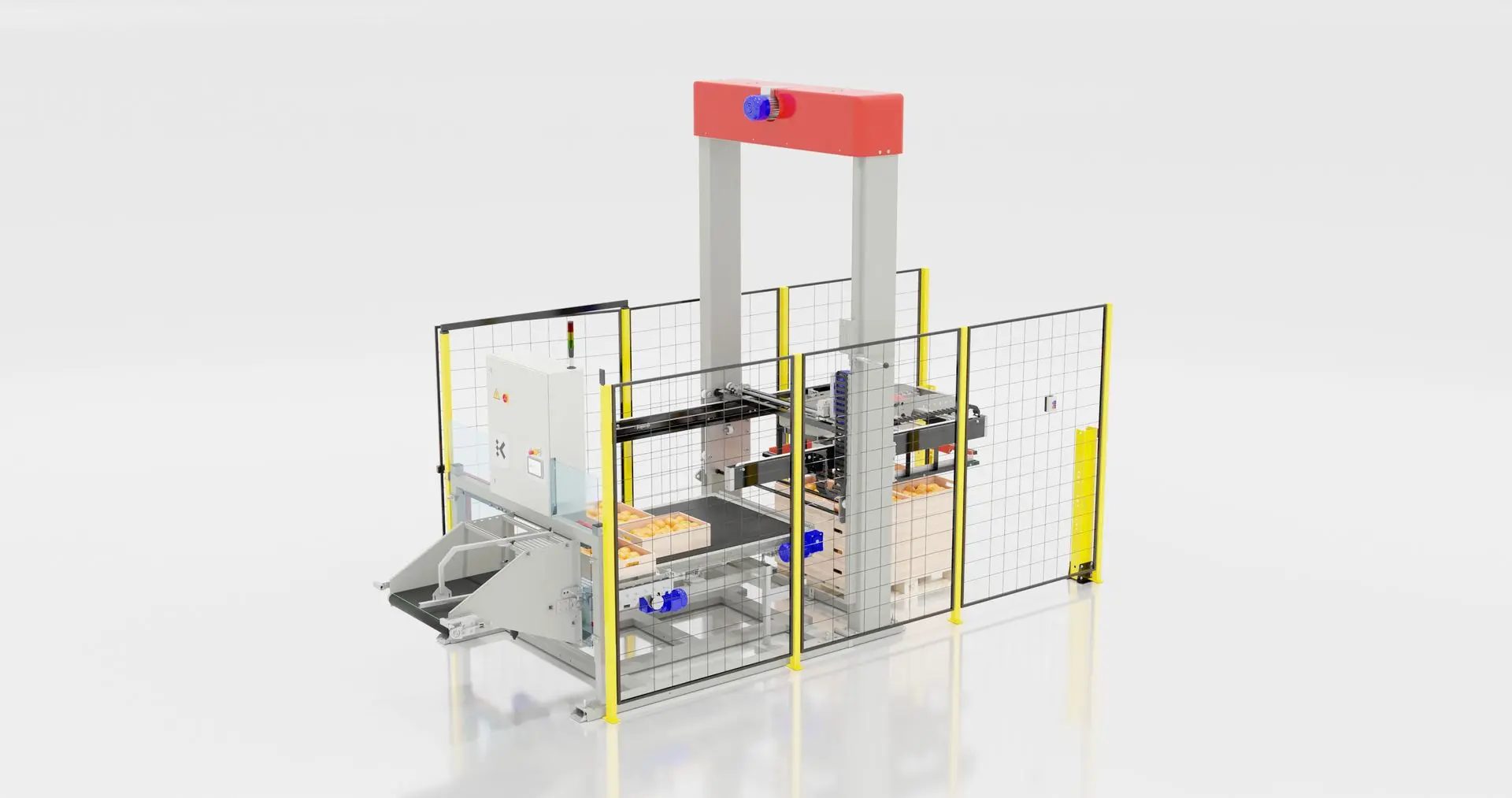

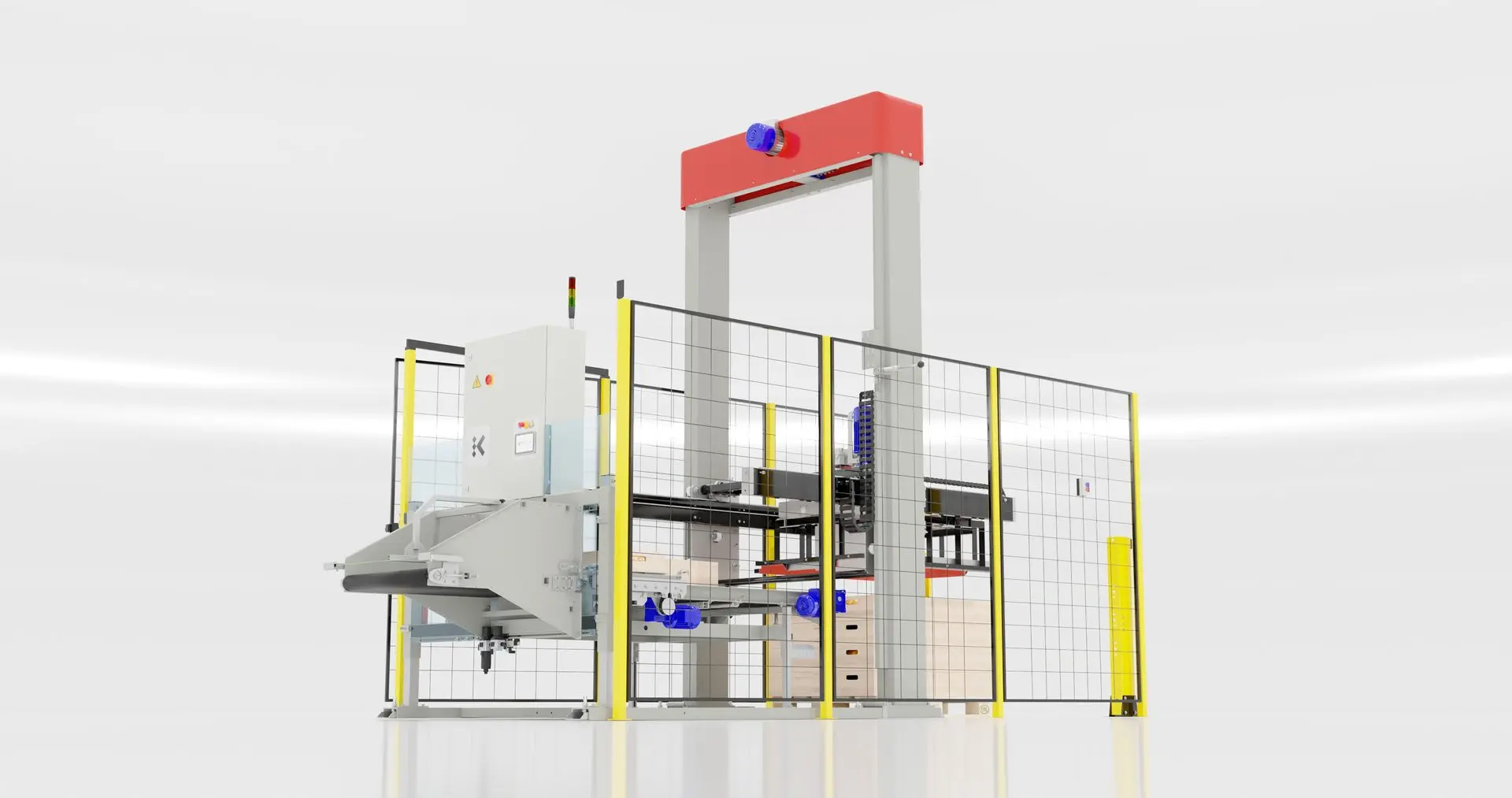

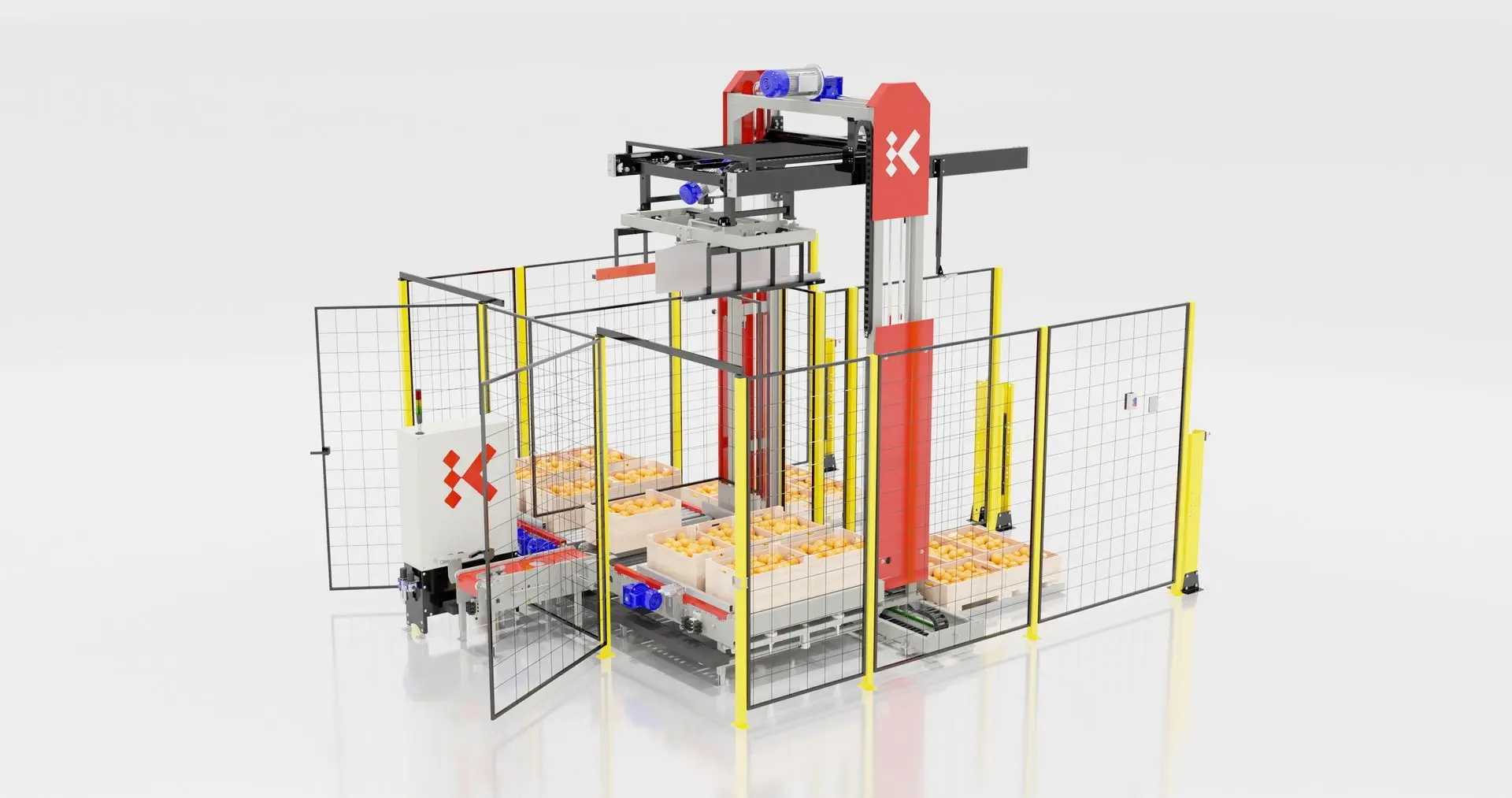

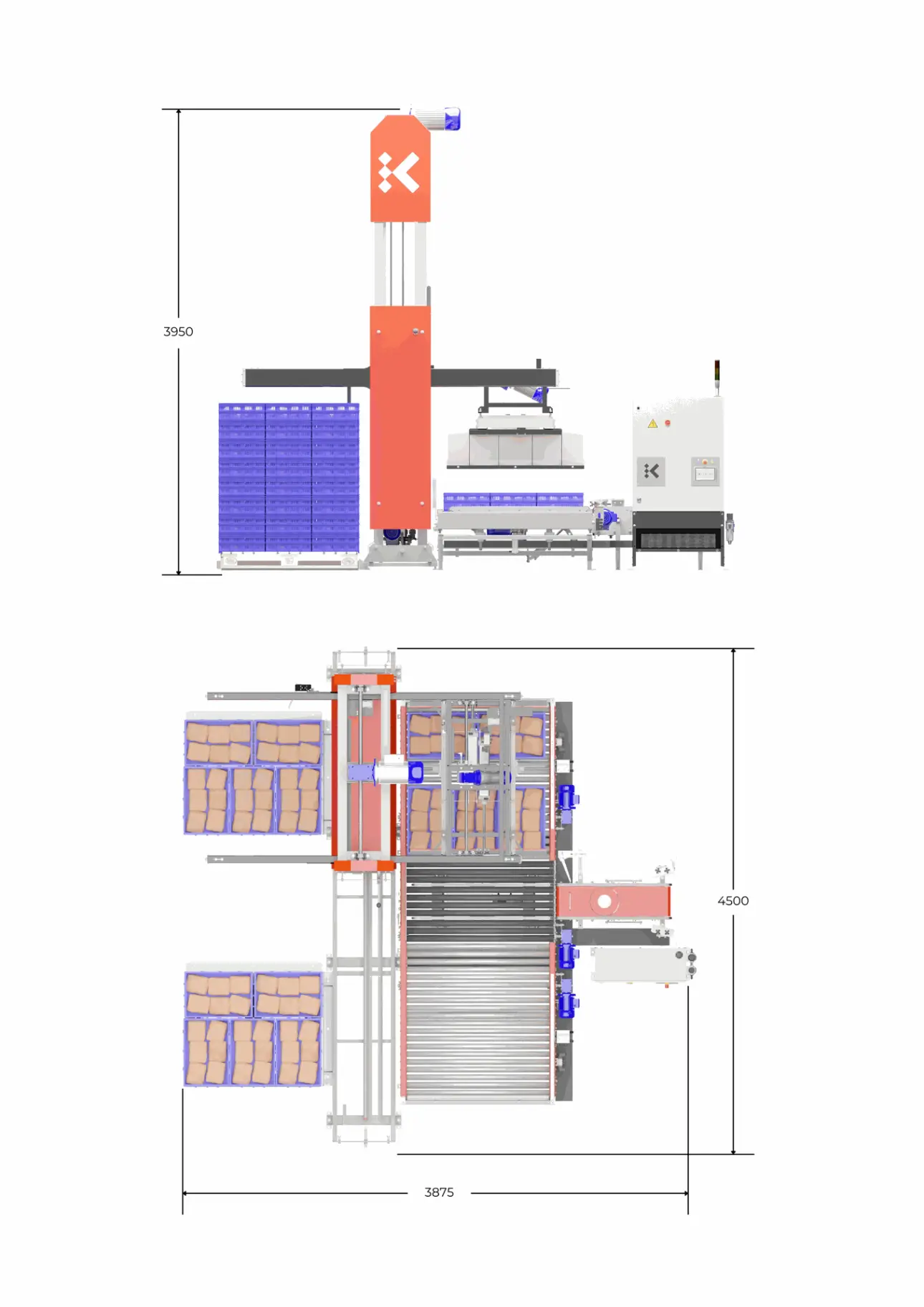

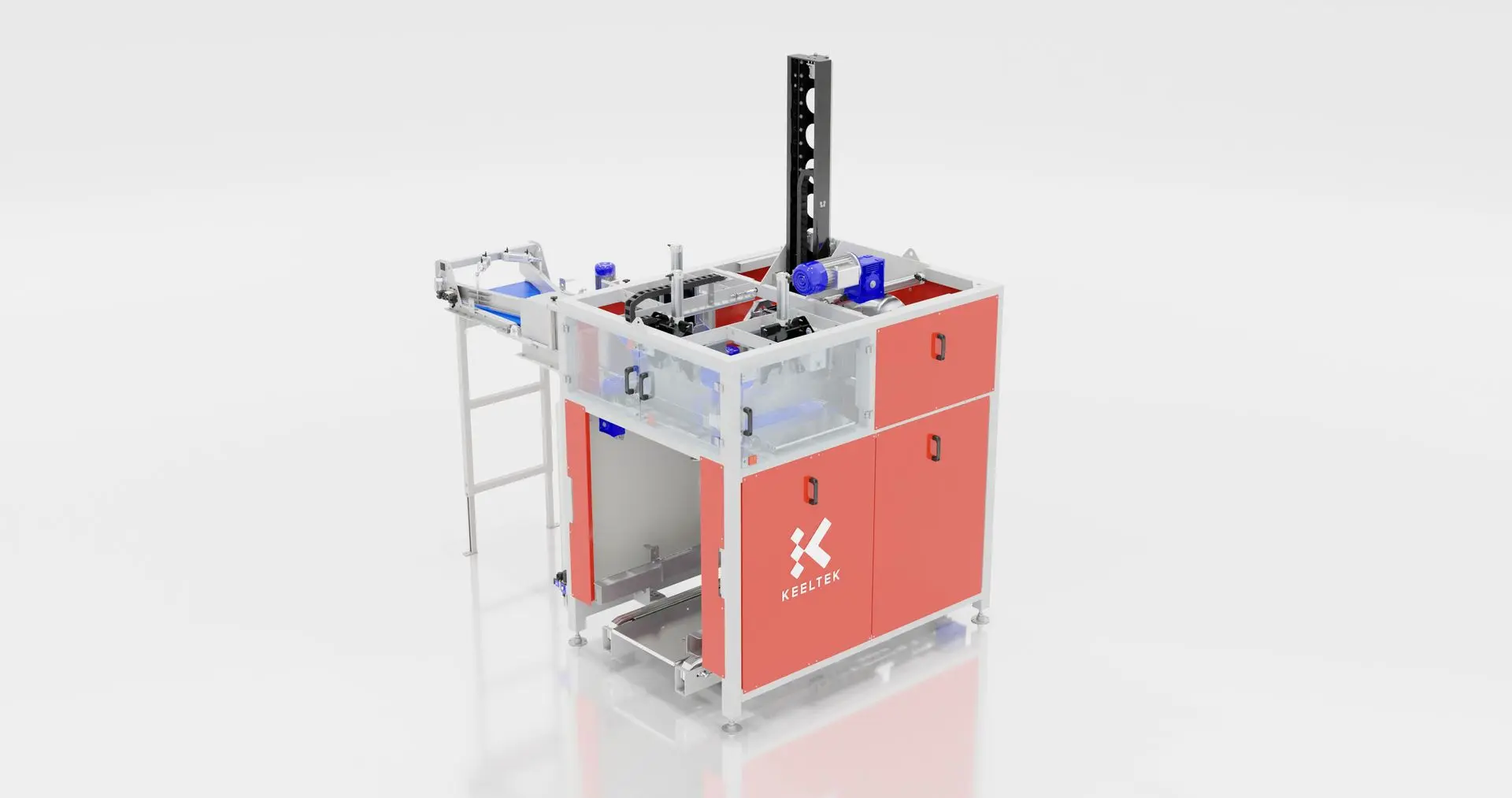

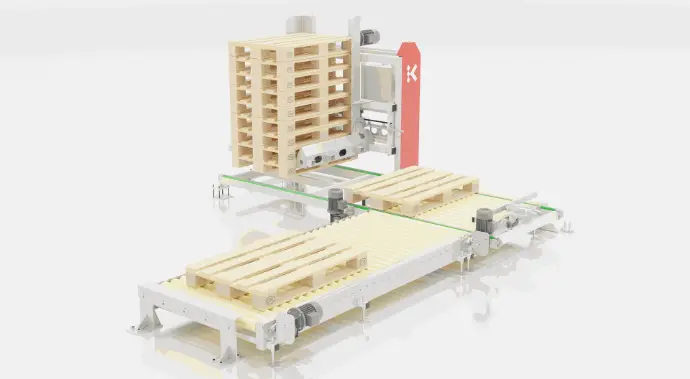

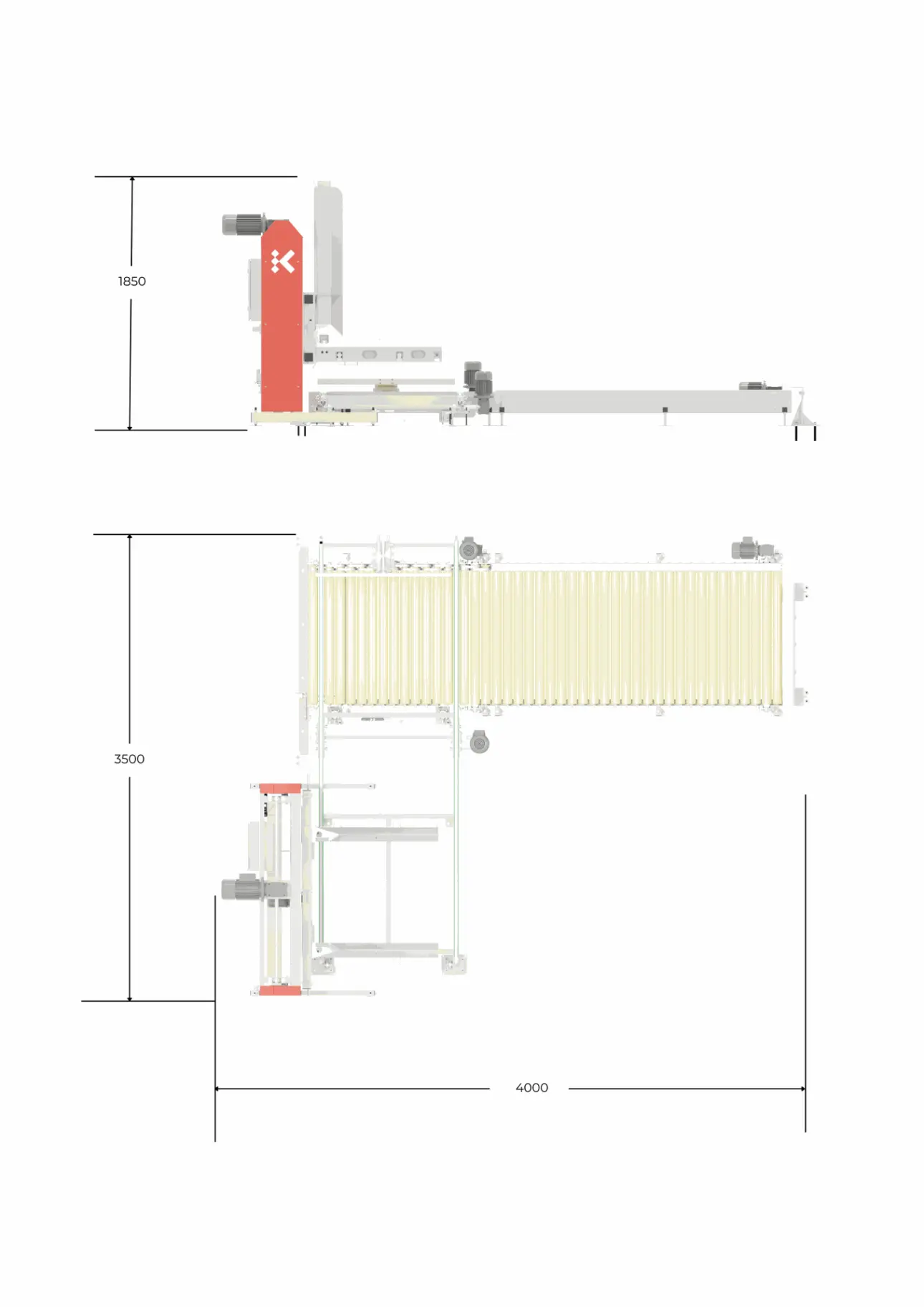

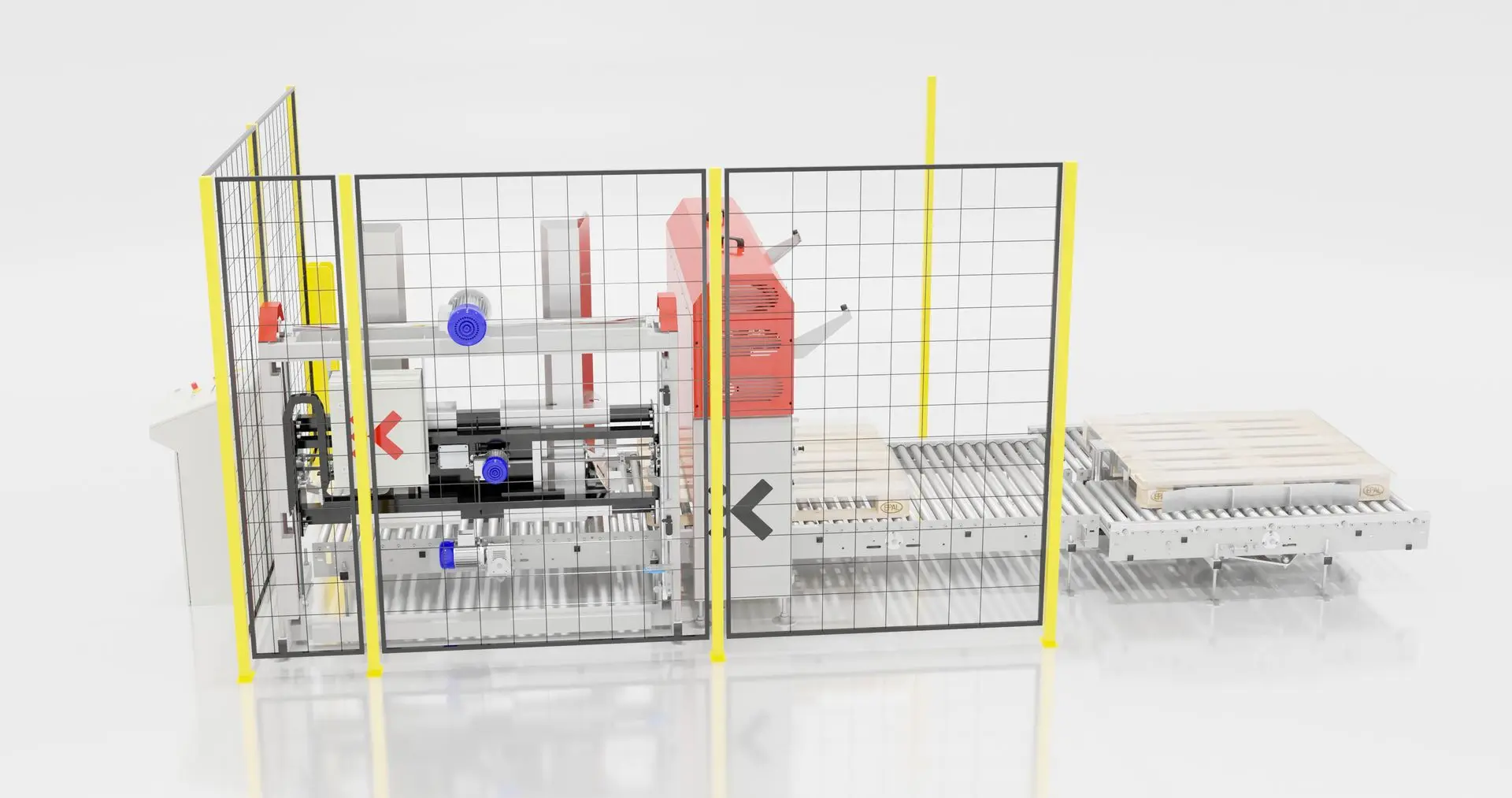

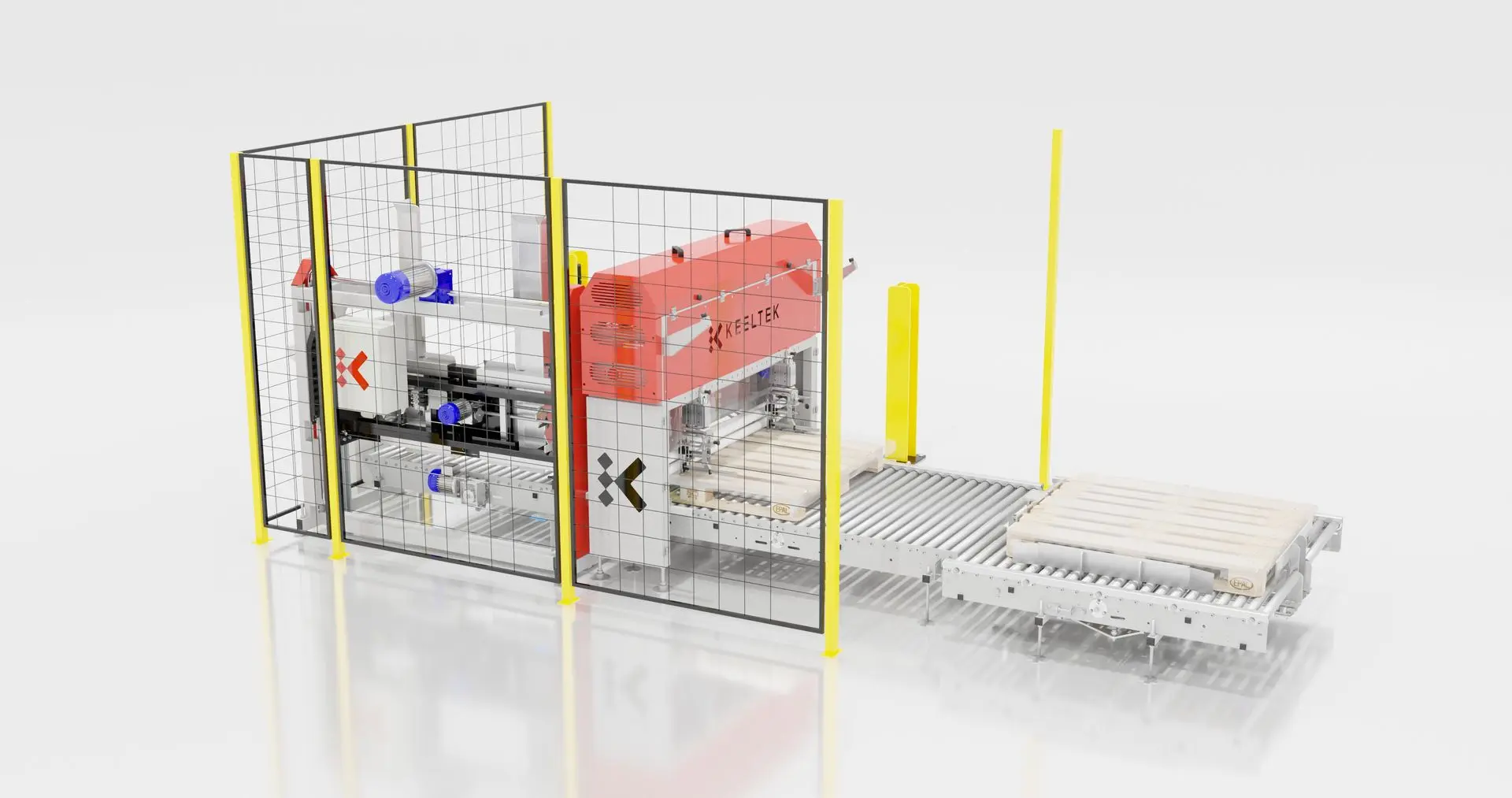

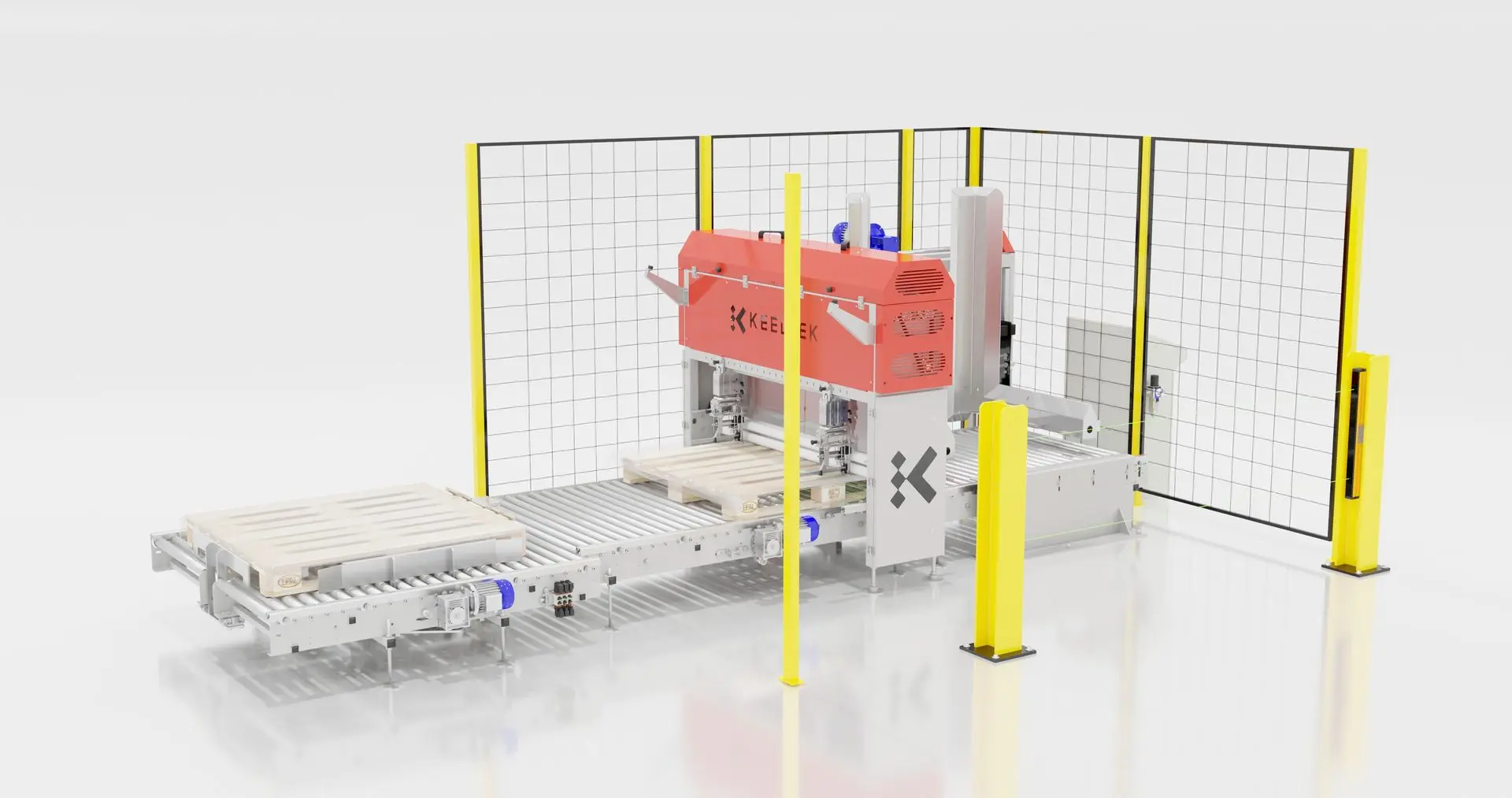

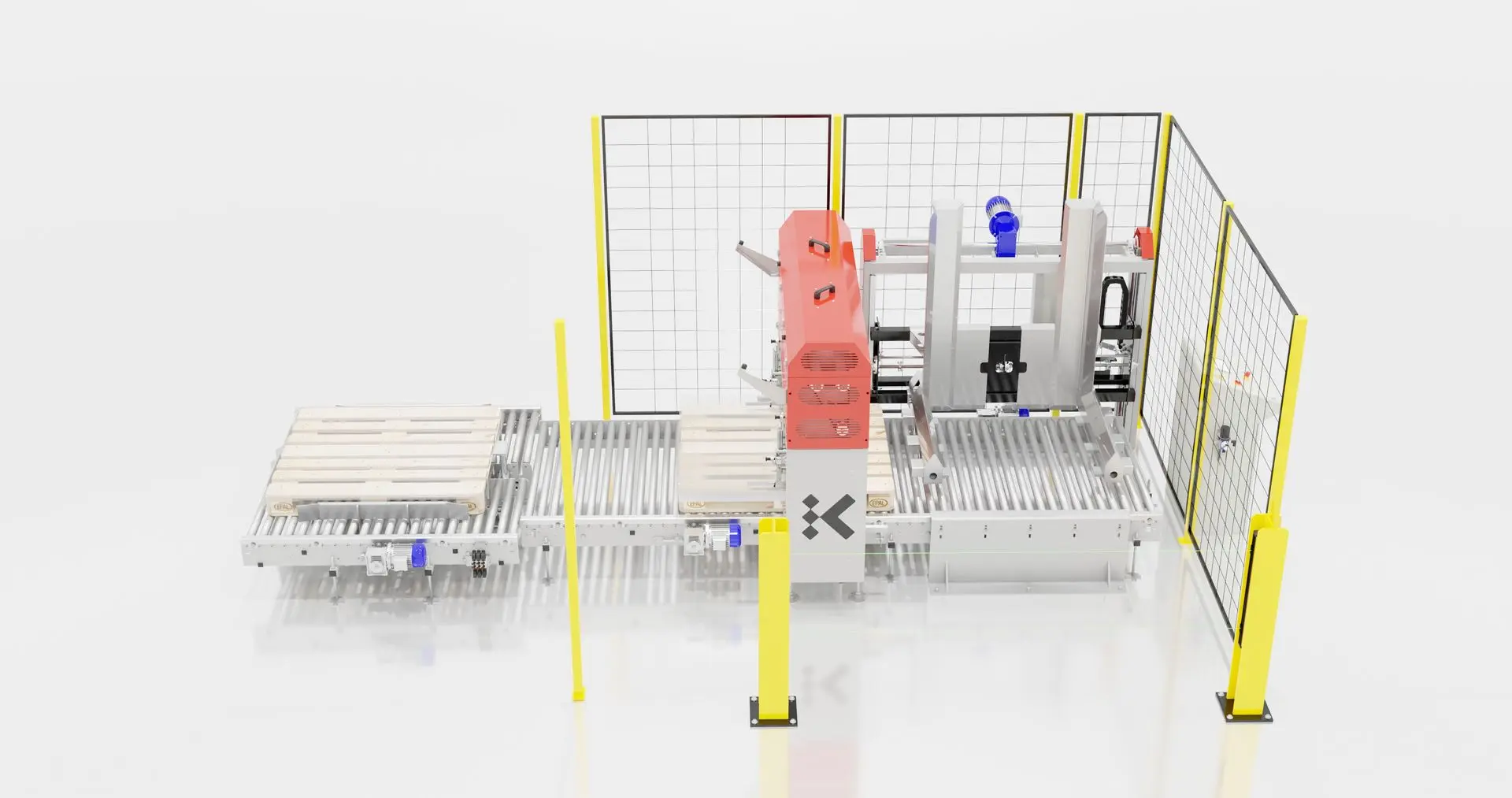

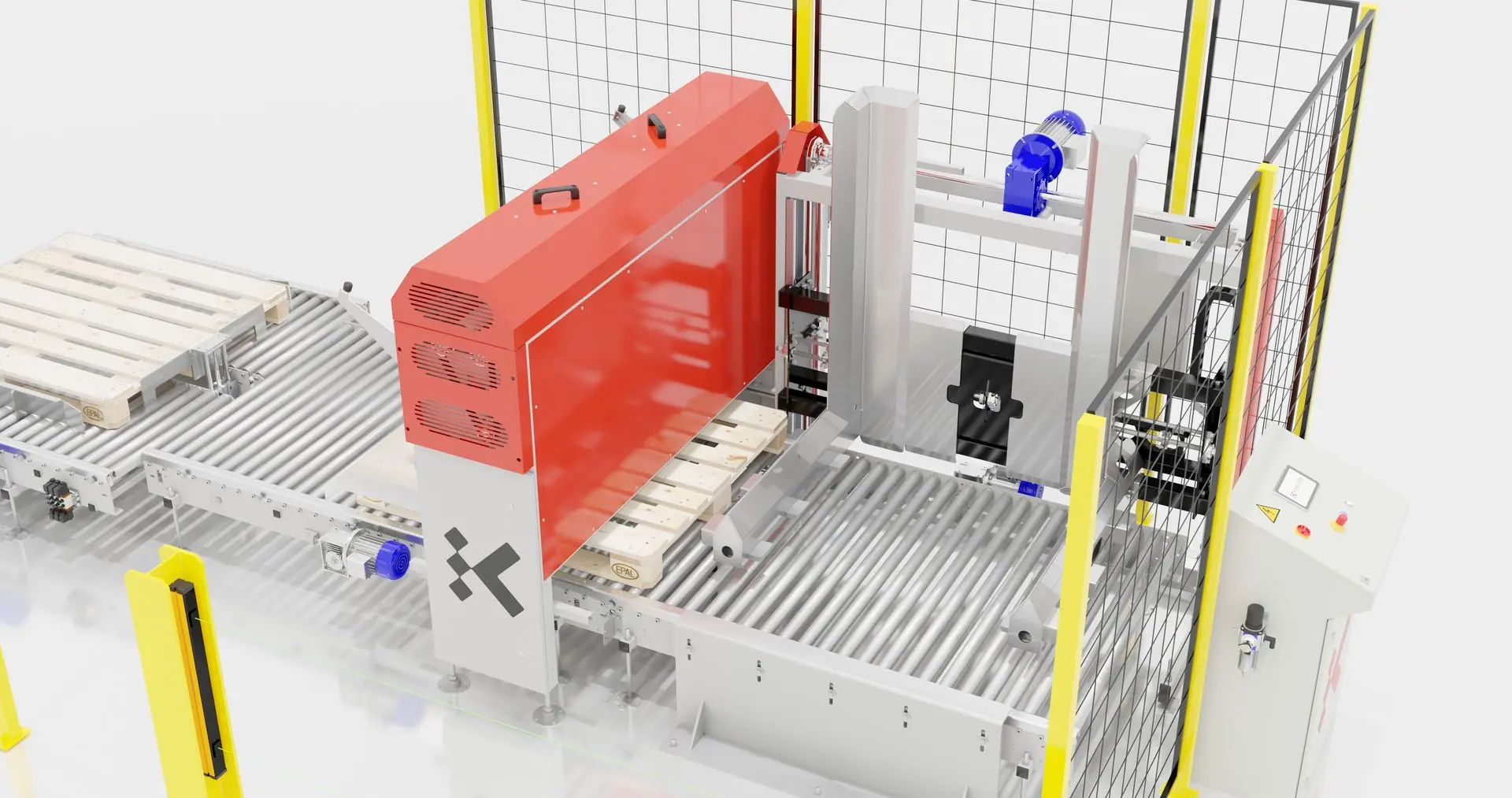

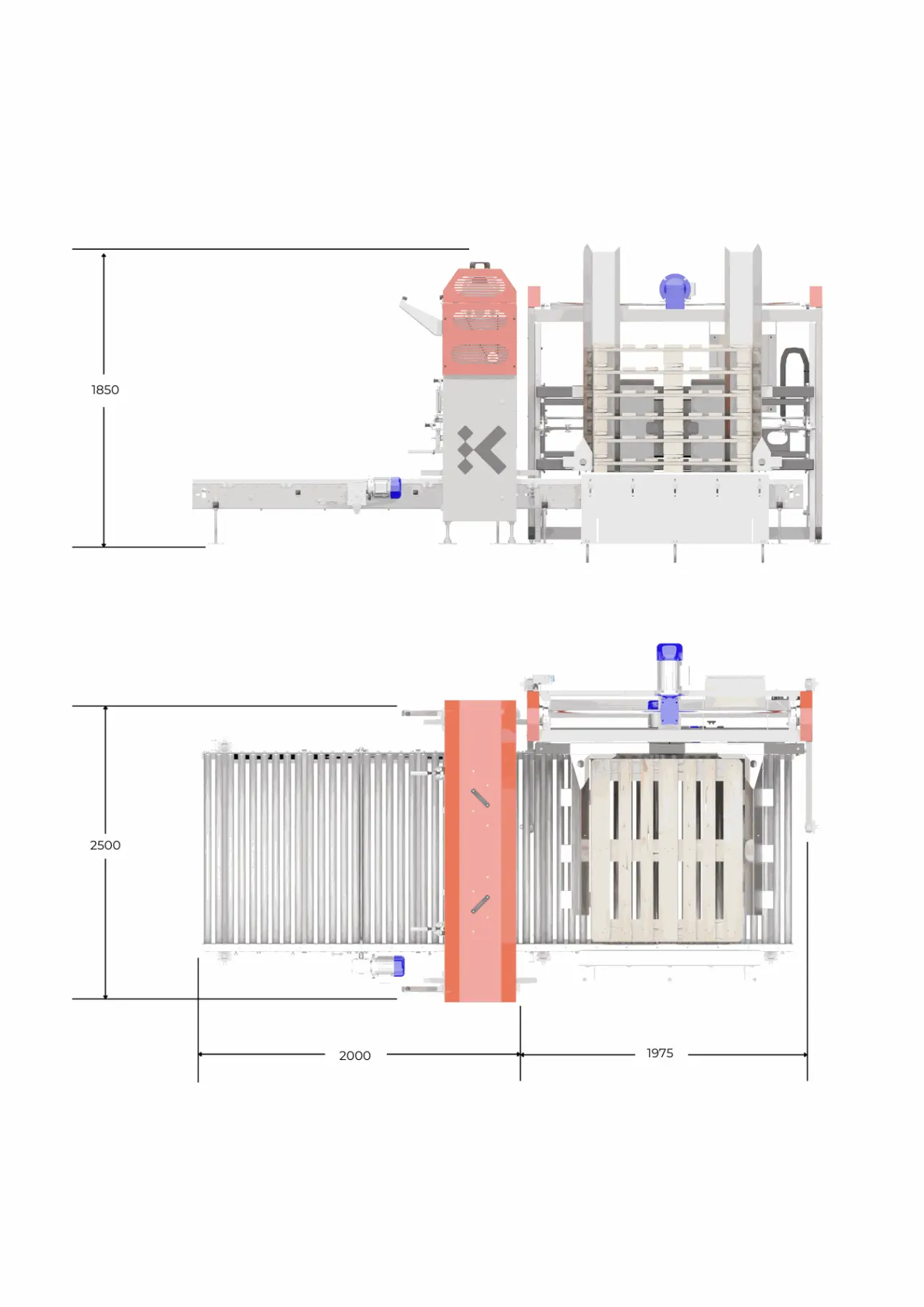

EASYPAL PLUS

2-axis Cartesian palletizer for boxes with pallet destacker

2-axis Cartesian palletizer with combined chain and roller table, with box gripping system using a clamp equipped with 2 or 4 jaws, designed for palletizing boxes in layers. It incorporates an automatic pallet destacker to maximize production and avoid unnecessary stoppages to replenish the pallet.

EASYPAL PLUS

2-axis Cartesian palletizer for boxes with pallet destacker

2-axis Cartesian palletizer with combined chain and roller table, with box gripping system using a clamp equipped with 2 or 4 jaws, designed for palletizing boxes in layers. It incorporates an automatic pallet destacker to maximize production and avoid unnecessary stoppages to replenish the pallet.

EASYPAL PLUS

2-axis Cartesian palletizer for boxes with pallet destacker

2-axis Cartesian palletizer with combined chain and roller table, with box gripping system using a clamp equipped with 2 or 4 jaws, designed for palletizing boxes in layers. It incorporates an automatic pallet destacker to maximize production and avoid unnecessary stoppages to replenish the pallet.

EASYPAL PLUS

2-axis Cartesian palletizer for boxes with pallet destacker

2-axis Cartesian palletizer with combined chain and roller table, with box gripping system using a clamp equipped with 2 or 4 jaws, designed for palletizing boxes in layers. It incorporates an automatic pallet destacker to maximize production and avoid unnecessary stoppages to replenish the pallet.

EASYPAL PLUS

2-axis Cartesian palletizer for boxes with pallet destacker

2-axis Cartesian palletizer with combined chain and roller table, with box gripping system using a clamp equipped with 2 or 4 jaws, designed for palletizing boxes in layers. It incorporates an automatic pallet destacker to maximize production and avoid unnecessary stoppages to replenish the pallet.

| Reference product | Boxes of any size compatible with the pallet |

| Tiles | Any tile configuration. |

| Maximum permissible load | Up to 175 kg. |

|

Connectivity

|

Industry 4.0 Ready |

| Cadences | Up to 3 shots per minute. |

Equipment | Automatic pallet dispenser |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Features:

- Simple and intuitive creation of mosaics by the operator using proprietary software.

- Reversed layer function for improved stability.

Safety and ergonomy:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed by laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Rotator with selectable label positioning, high performance.

- Labeling machine integration.

- Reversed layer function for improved stability.

- Add pallet between layers function. (Manual or automatic).

- KTS, remote assistance.

- Full stainless steel finishes

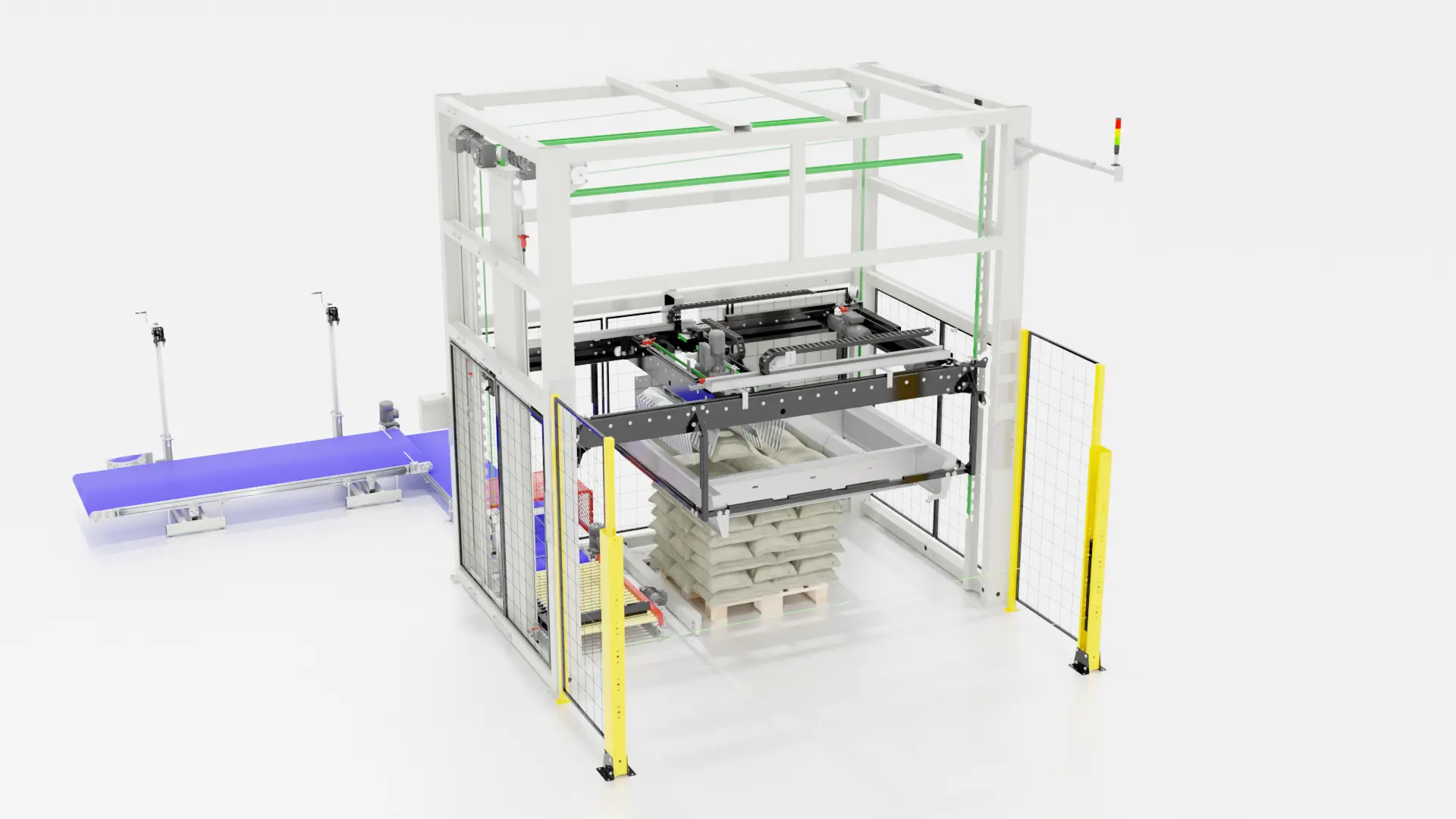

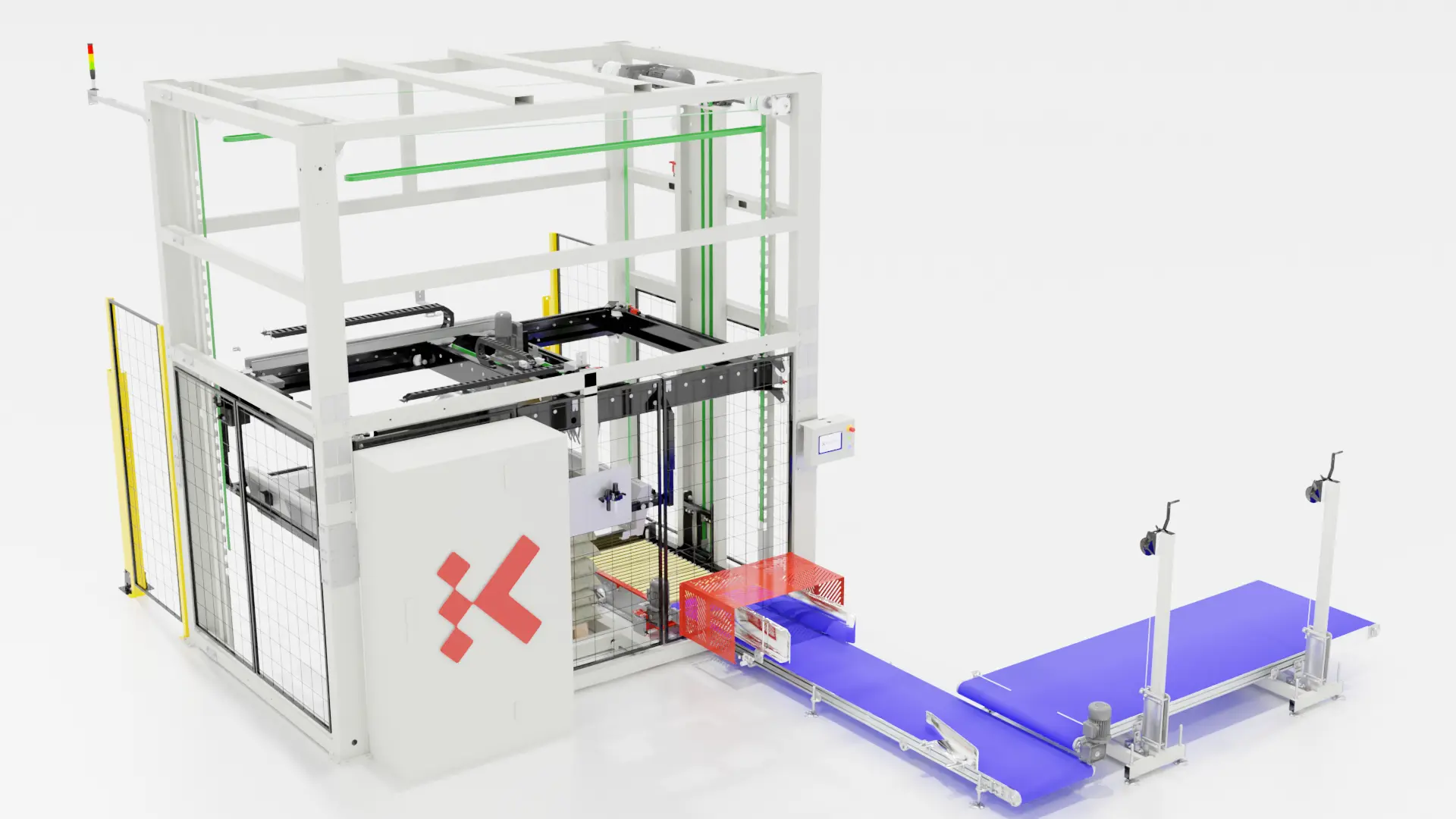

BAGPAL

4-axis Cartesian palletizer for bags

4-axis Cartesian palletizer with gripper and rotation system, primarily designed for palletizing bags, but capable of handling other products.

BAGPAL

4-axis Cartesian palletizer for bags

4-axis Cartesian palletizer with gripper and rotation system, primarily designed for palletizing bags, but capable of handling other products.

BAGPAL

4-axis Cartesian palletizer for bags

4-axis Cartesian palletizer with gripper and rotation system, primarily designed for palletizing bags, but capable of handling other products.

BAGPAL

4-axis Cartesian palletizer for bags

4-axis Cartesian palletizer with gripper and rotation system, primarily designed for palletizing bags, but capable of handling other products.

BAGPAL

4-axis Cartesian palletizer for bags

4-axis Cartesian palletizer with gripper and rotation system, primarily designed for palletizing bags, but capable of handling other products.

BAGPAL

4-axis Cartesian palletizer for bags

4-axis Cartesian palletizer with gripper and rotation system, primarily designed for palletizing bags, but capable of handling other products.

BAGPAL

4-axis Cartesian palletizer for bags

4-axis Cartesian palletizer with gripper and rotation system, primarily designed for palletizing bags, but capable of handling other products.

| Reference product | Bags from 5 to 50 kg. For other formats, please inquire. |

| Tiles | Any tile configuration. |

| Maximum permissible load | Up to 50 kg |

|

Connectivity

|

Industry 4.0 Ready |

| Cadences | Up to 10 cycles per minute |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Features:

- Simple and intuitive creation of mosaics by the operator using proprietary software.

- Reversed layer function for improved stability.

Safety and ergonomy:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed by laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Automatic pallet dispenser and changer.

- Multi-clamp for boxes and bags.

- KTS, remote assistance.

- Full stainless steel finishes

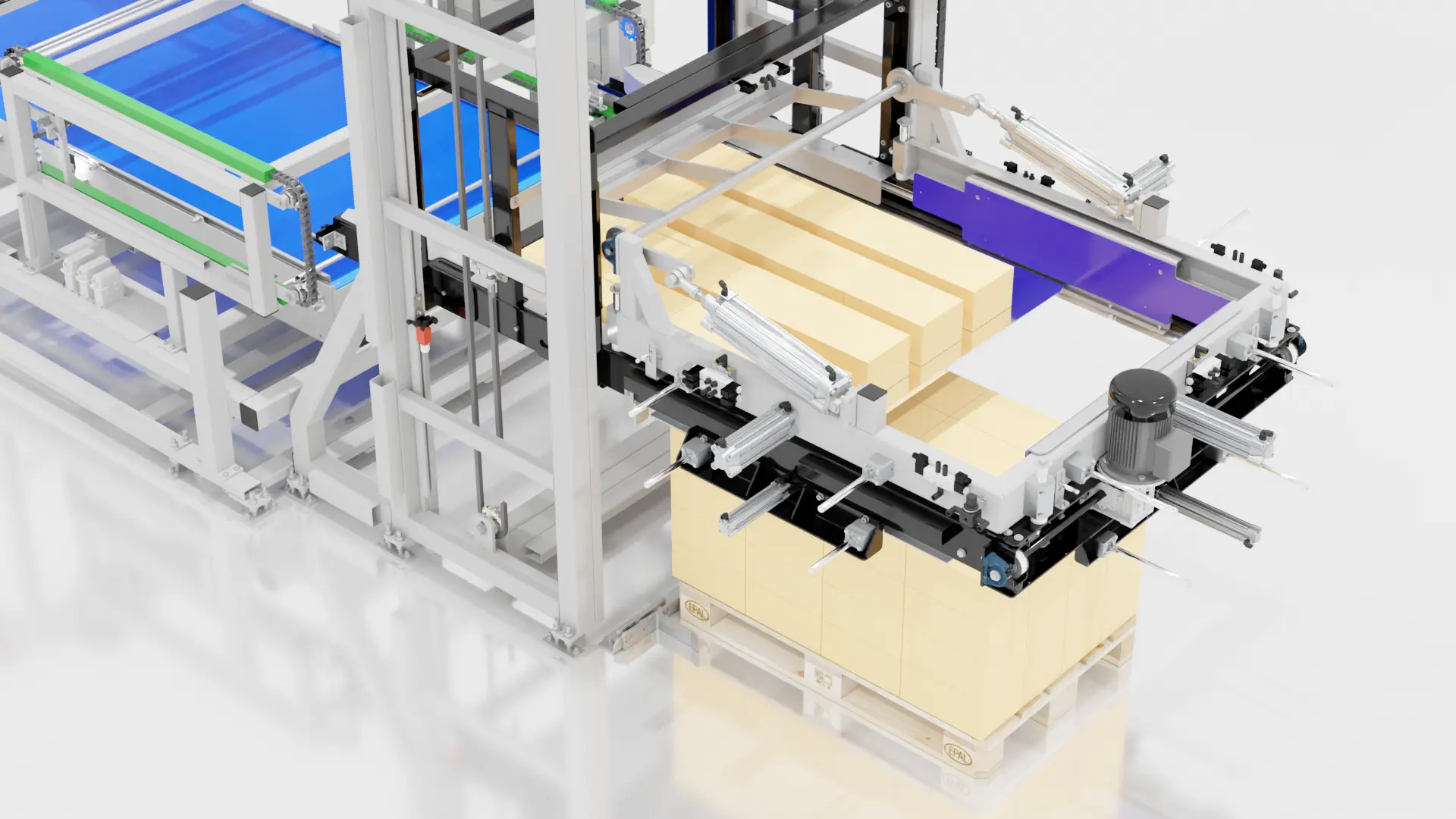

PLATEPAL

Cartesian layer palletizer with horizontal plate

2-axis Cartesian palletizer with horizontal plate, with box positioning and rotation system, designed for palletizing layers of boxes containing products that cannot withstand much lateral pressure.

PLATEPAL

Cartesian layer palletizer with horizontal plate

2-axis Cartesian palletizer with horizontal plate, with box positioning and rotation system, designed for palletizing layers of boxes containing products that cannot withstand much lateral pressure.

PLATEPAL

Cartesian layer palletizer with horizontal plate

2-axis Cartesian palletizer with horizontal plate, with box positioning and rotation system, designed for palletizing layers of boxes containing products that cannot withstand much lateral pressure.

PLATEPAL

Cartesian layer palletizer with horizontal plate

2-axis Cartesian palletizer with horizontal plate, with box positioning and rotation system, designed for palletizing layers of boxes containing products that cannot withstand much lateral pressure.

PLATEPAL

Cartesian layer palletizer with horizontal plate

2-axis Cartesian palletizer with horizontal plate, with box positioning and rotation system, designed for palletizing layers of boxes containing products that cannot withstand much lateral pressure.

| Reference product | Boxes of any size compatible with the pallet |

| Tiles | Any tile configuration. |

| Maximum permissible load | Up to 175 kg |

|

Connectivity

|

Industry 4.0 Ready |

| Cadences | Up to 3 shots per minute |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Features:

- Simple and intuitive creation of mosaics by the operator using proprietary software.

- Reversed layer function for improved stability.

Safety and ergonomy:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed by laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Rotator with selectable label positioning, high performance.

- Labeling machine integration.

- Automatic pallet dispenser and changer.

- Add pallet between layers function. (Manual or automatic)

- KTS, remote assistance.

- Full stainless steel finishes

UNIPAL

Two-axis Cartesian palletizer by layers for any type of box

2-axis Cartesian palletizer with combined canvas and roller table, with box gripping system using a clamp equipped with 4 jaws, designed for palletizing layers of any type of box.

UNIPAL

Two-axis Cartesian palletizer by layers for any type of box

2-axis Cartesian palletizer with combined canvas and roller table, with box gripping system using a clamp equipped with 4 jaws, designed for palletizing layers of any type of box.

UNIPAL

Two-axis Cartesian palletizer by layers for any type of box

2-axis Cartesian palletizer with combined canvas and roller table, with box gripping system using a clamp equipped with 4 jaws, designed for palletizing layers of any type of box.

UNIPAL

Two-axis Cartesian palletizer by layers for any type of box

2-axis Cartesian palletizer with combined canvas and roller table, with box gripping system using a clamp equipped with 4 jaws, designed for palletizing layers of any type of box.

UNIPAL

Two-axis Cartesian palletizer by layers for any type of box

2-axis Cartesian palletizer with combined canvas and roller table, with box gripping system using a clamp equipped with 4 jaws, designed for palletizing layers of any type of box.

| Reference product | Boxes of any size compatible with the pallet |

| Tiles | Any tile configuration. |

| Maximum permissible load | Up to 175 kg. |

|

Connectivity

|

Industry 4.0 Ready |

| Cadences | Up to 3 shots per minute. |

Equipment | Rotator with selectable label positioning. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Features:

- Simple and intuitive creation of mosaics by the operator using proprietary software.

- Reversed layer function for improved stability.

Safety and ergonomy:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed by laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Rotator with selectable label positioning.

- Labeling machine integration.

- Automatic pallet dispenser and changer.

- Reversed layer function for improved stability.

- Add pallet between layers function. (Manual or automatic)

- KTS, remote assistance.

- Full stainless steel finishes

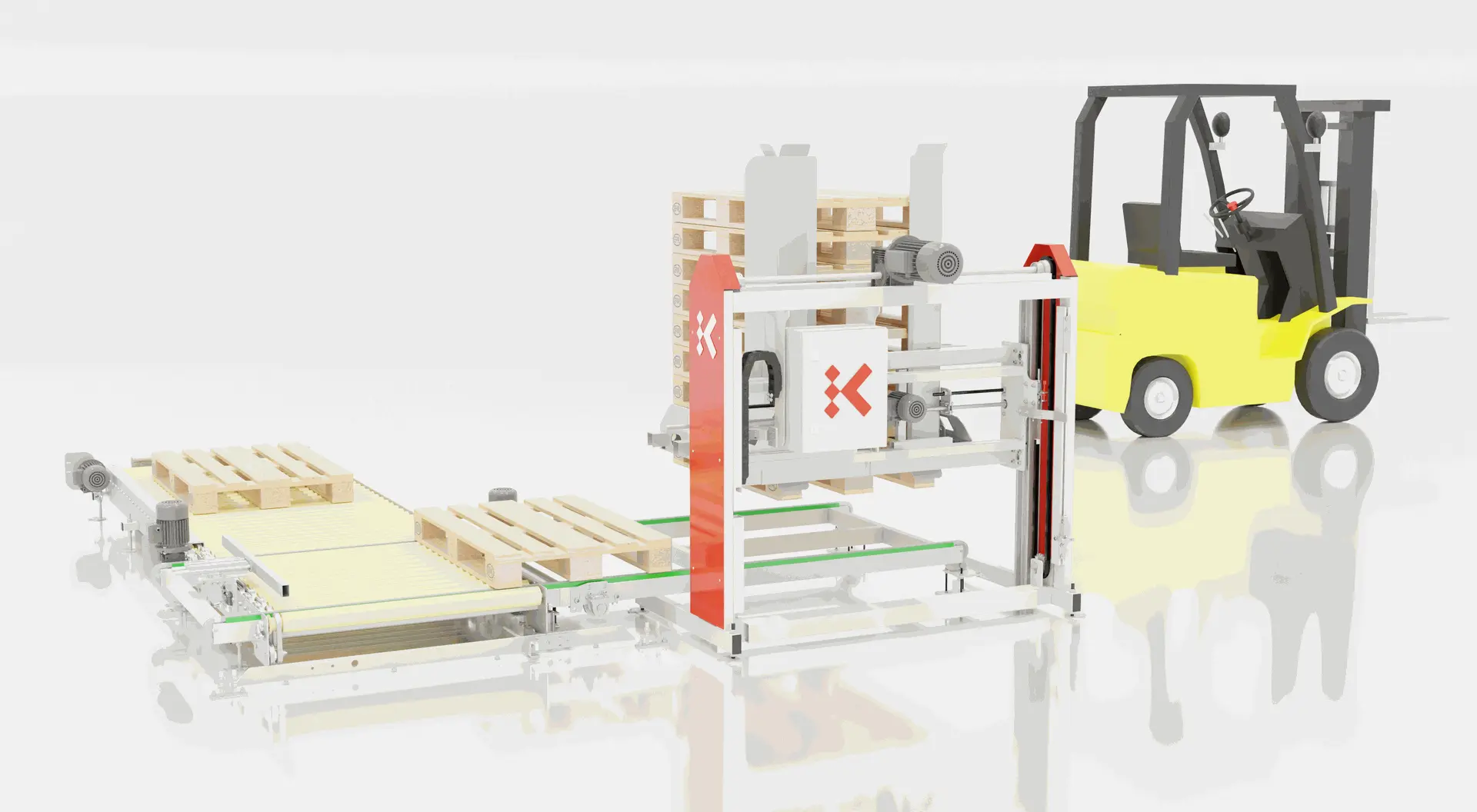

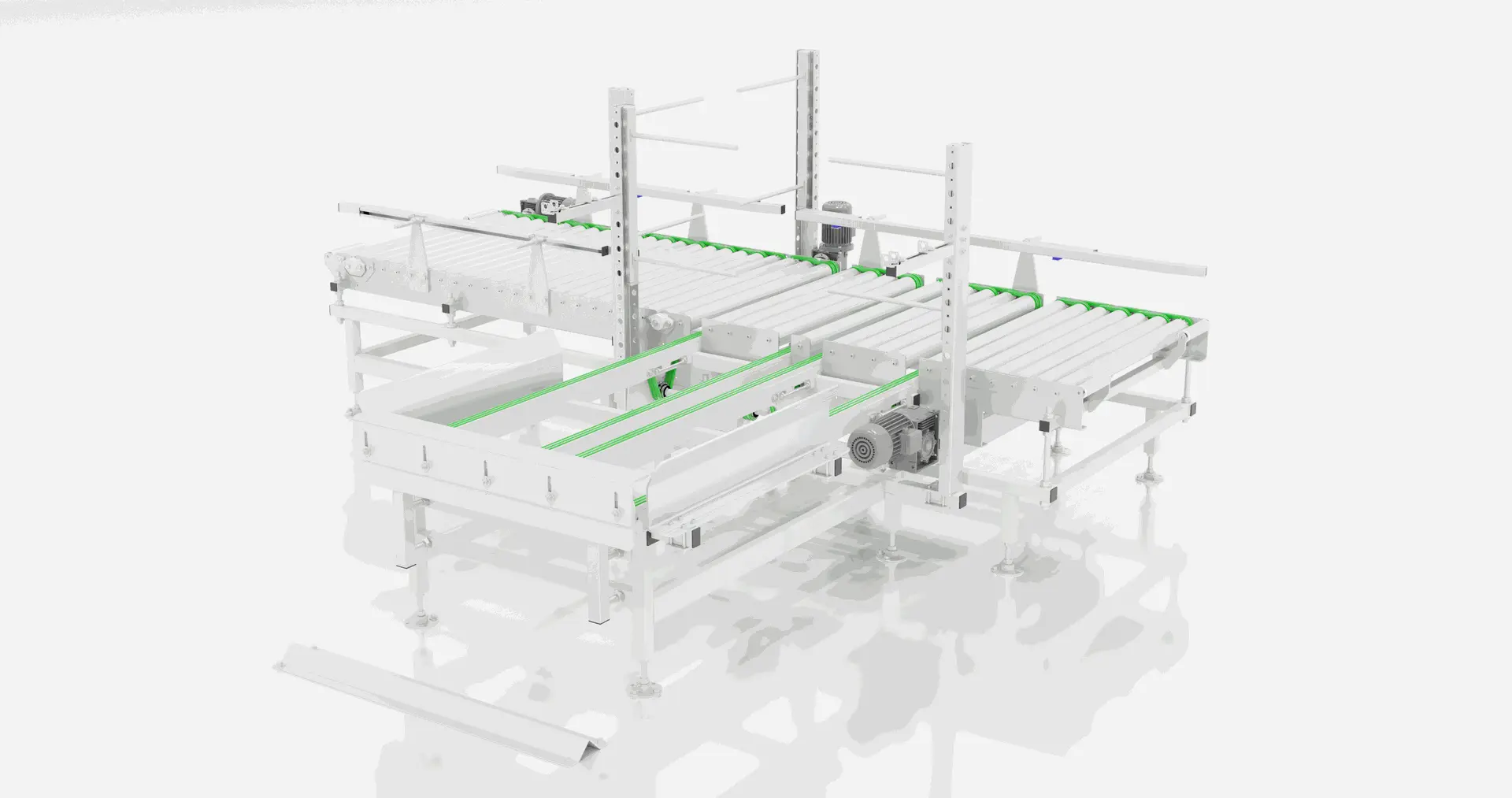

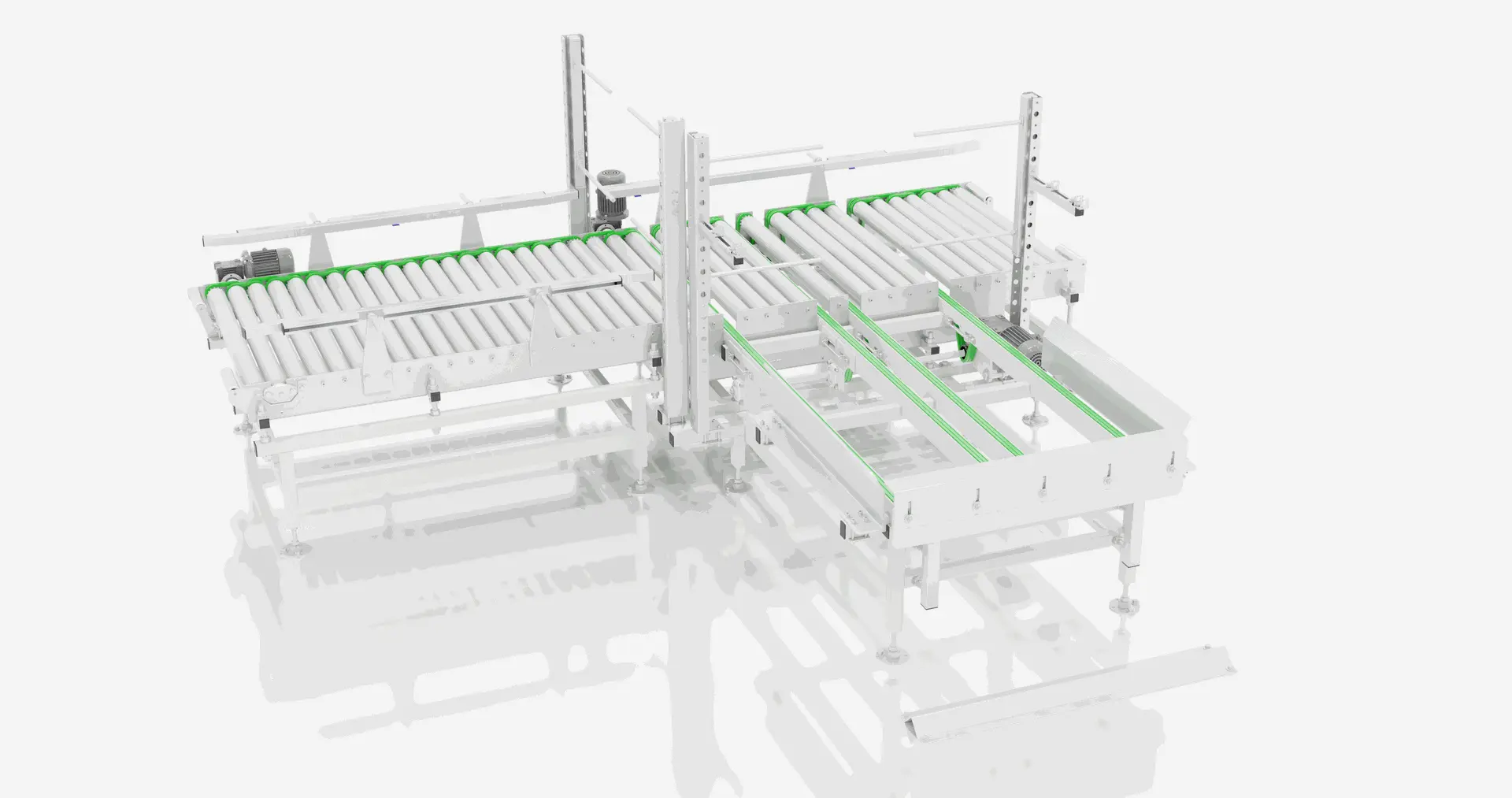

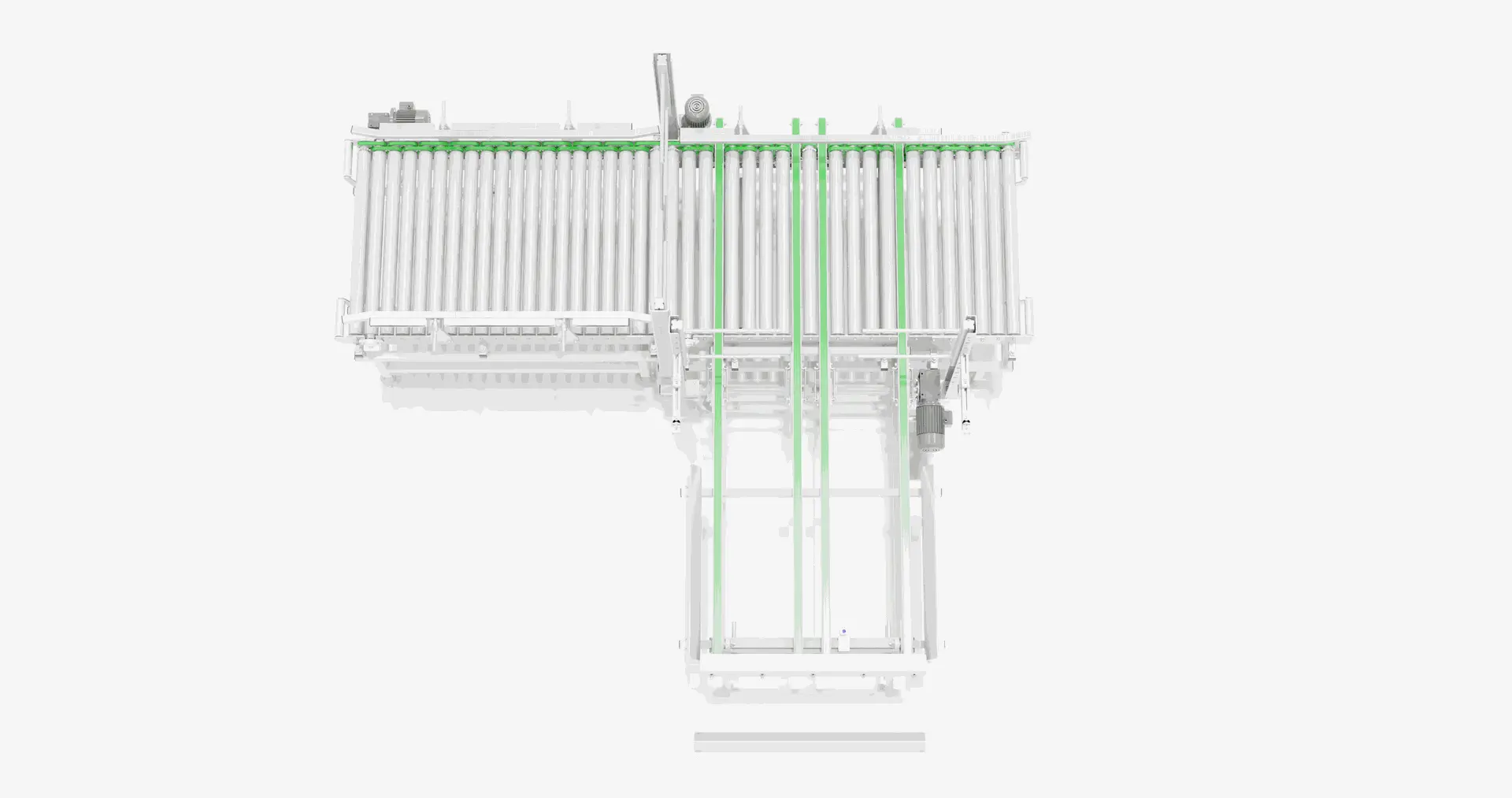

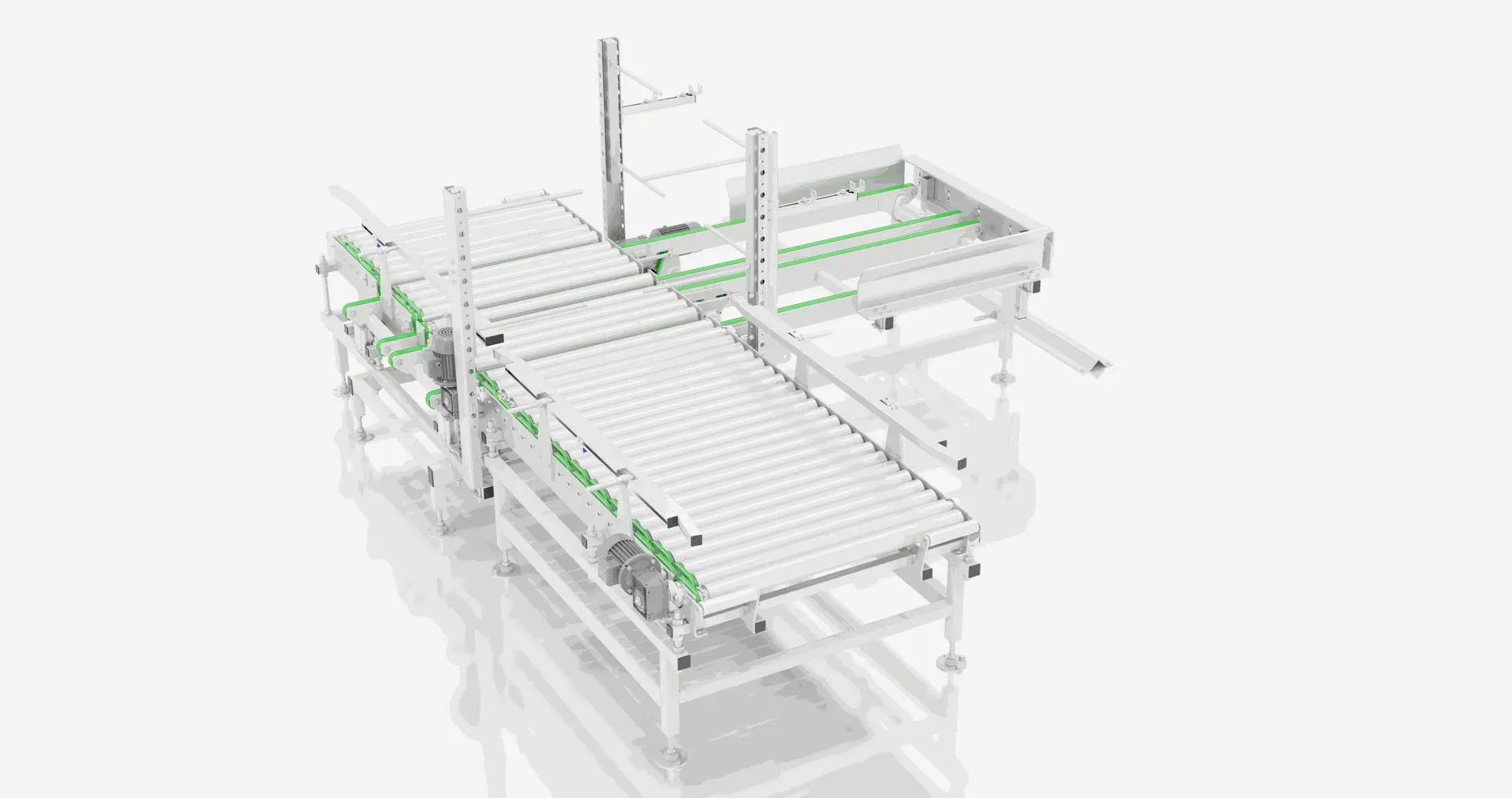

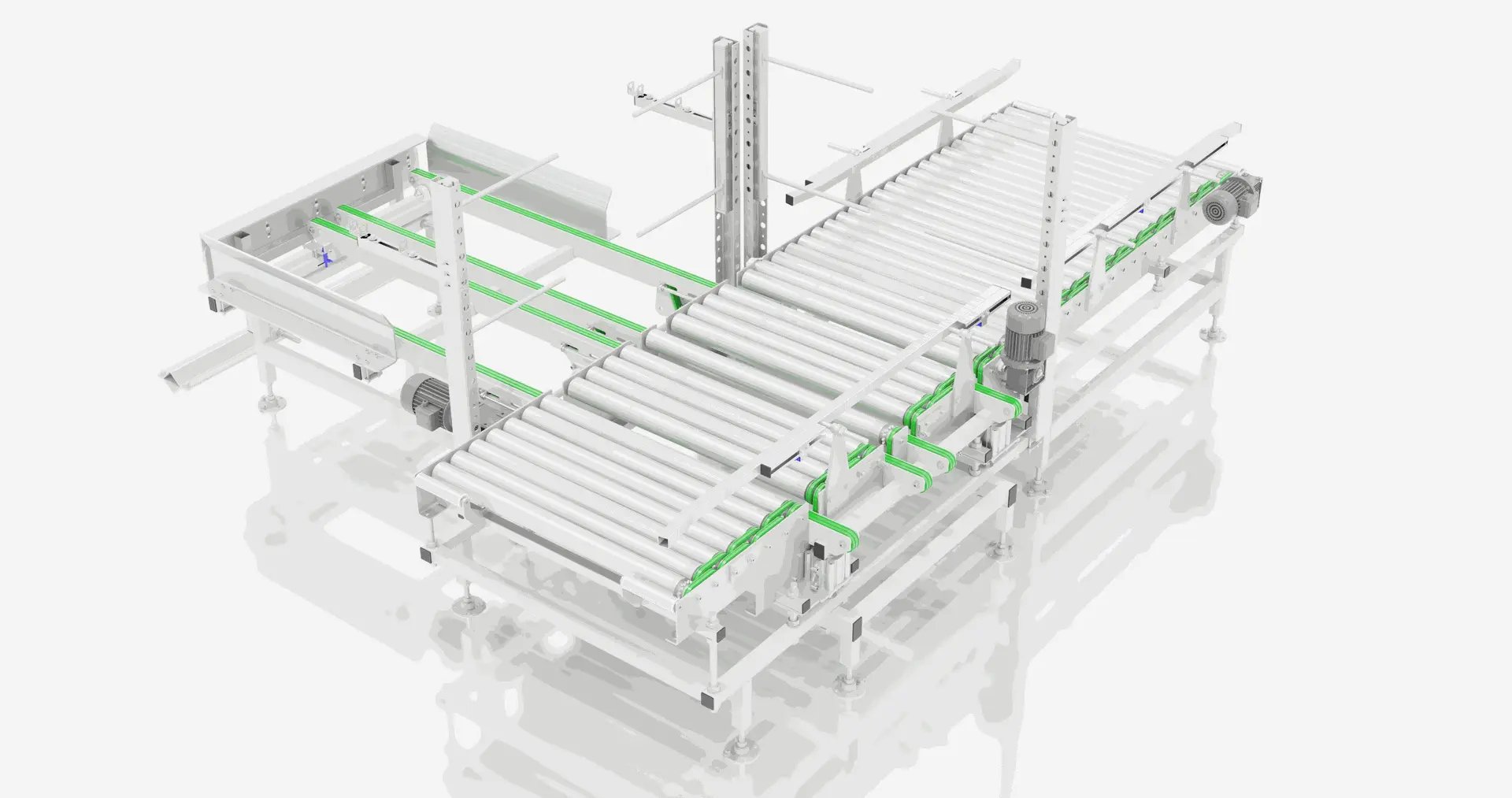

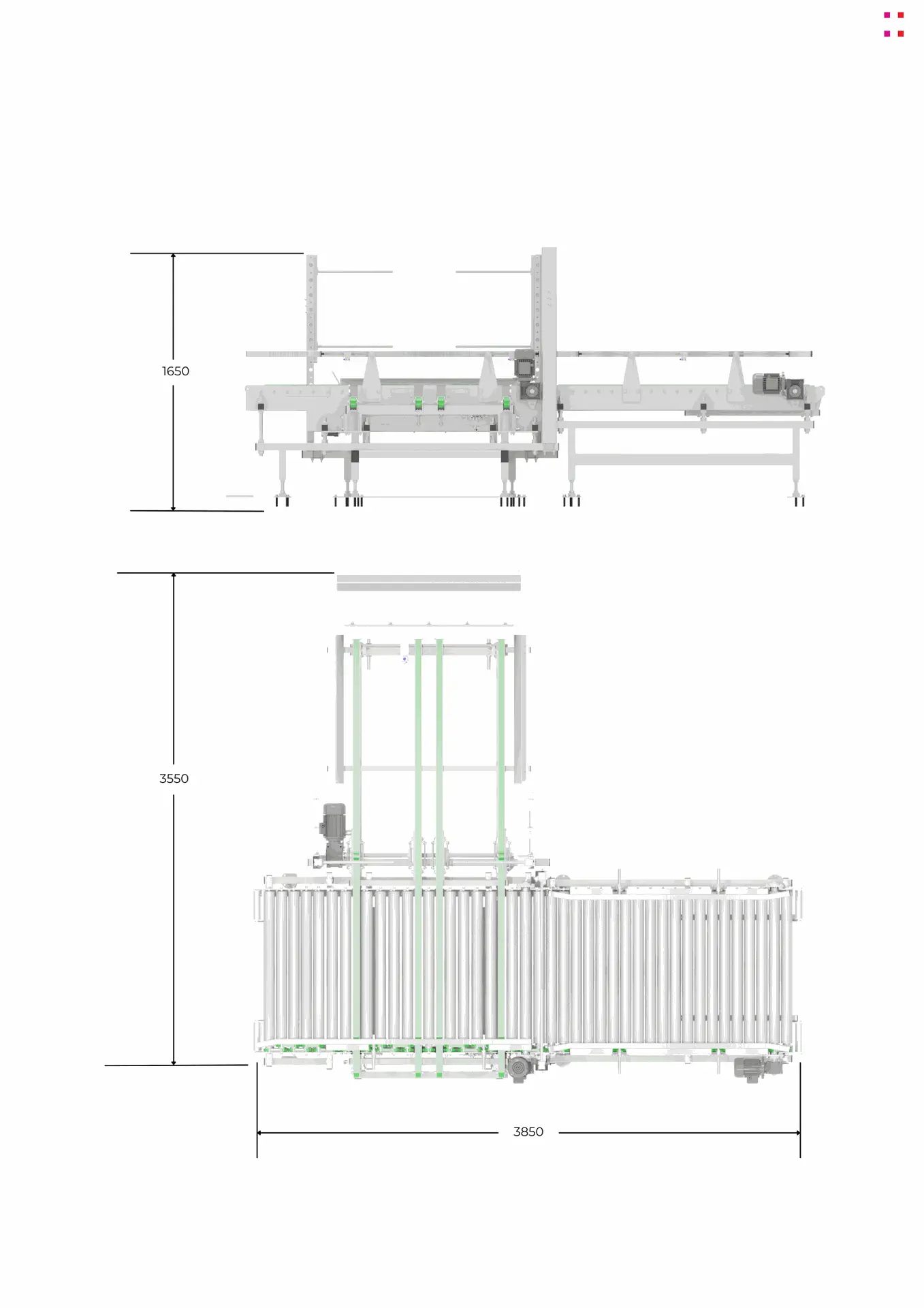

TRACKPAL

Cartesian layer palletizer on track

Two-axis Cartesian palletizer mounted on a track, enabling work in two different palletizing positions to maximize performance. The product is automatically diverted to the active palletizing area, achieving 100% continuous production.

TRACKPAL

Cartesian layer palletizer on track

Two-axis Cartesian palletizer mounted on a track, enabling work in two different palletizing positions to maximize performance. The product is automatically diverted to the active palletizing area, achieving 100% continuous production.

TRACKPAL

Cartesian layer palletizer on track

Two-axis Cartesian palletizer mounted on a track, enabling work in two different palletizing positions to maximize performance. The product is automatically diverted to the active palletizing area, achieving 100% continuous production.

TRACKPAL

Cartesian layer palletizer on track

Two-axis Cartesian palletizer mounted on a track, enabling work in two different palletizing positions to maximize performance. The product is automatically diverted to the active palletizing area, achieving 100% continuous production.

TRACKPAL

Cartesian layer palletizer on track

Two-axis Cartesian palletizer mounted on a track, enabling work in two different palletizing positions to maximize performance. The product is automatically diverted to the active palletizing area, achieving 100% continuous production.

| Reference product | Boxes of any size compatible with the pallet |

| Tiles | Any tile configuration. |

| Maximum permissible load | Up to 175 kg. |

|

Connectivity

|

Industry 4.0 Ready |

| Cadences | Up to 3 shots per minute. |

Equipment | Rotator with selectable label positioning. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Features:

- Simple and intuitive creation of mosaics by the operator using proprietary software.

- Reversed layer function for improved stability.

Safety and ergonomy:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed by laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Labeling machine integration.

- Automatic pallet dispenser and changer.

- Reversed layer function for improved stability.

- Add pallet between layers function. (Manual or automatic).

- KTS, remote assistance.

- Full stainless steel finishes

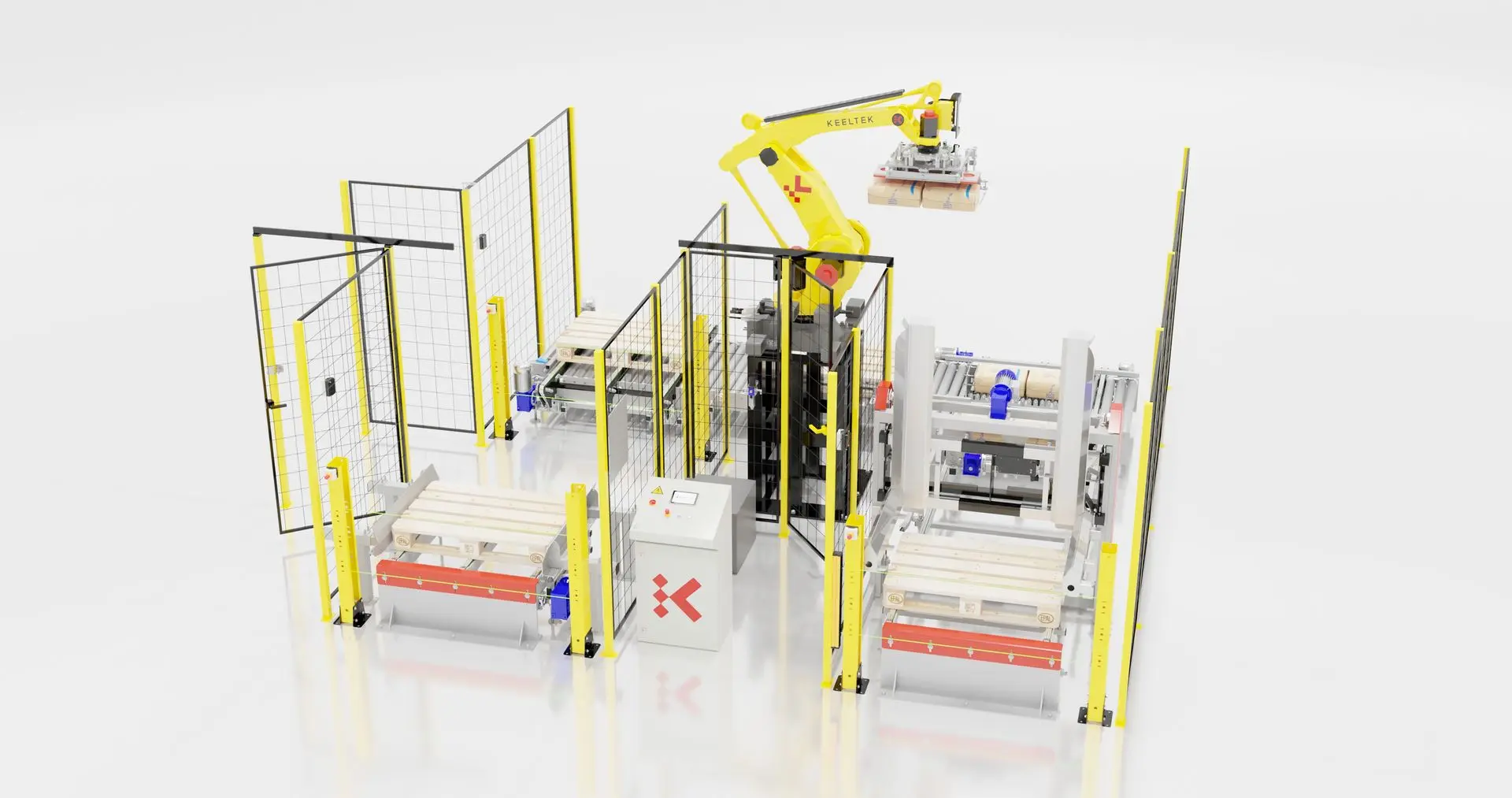

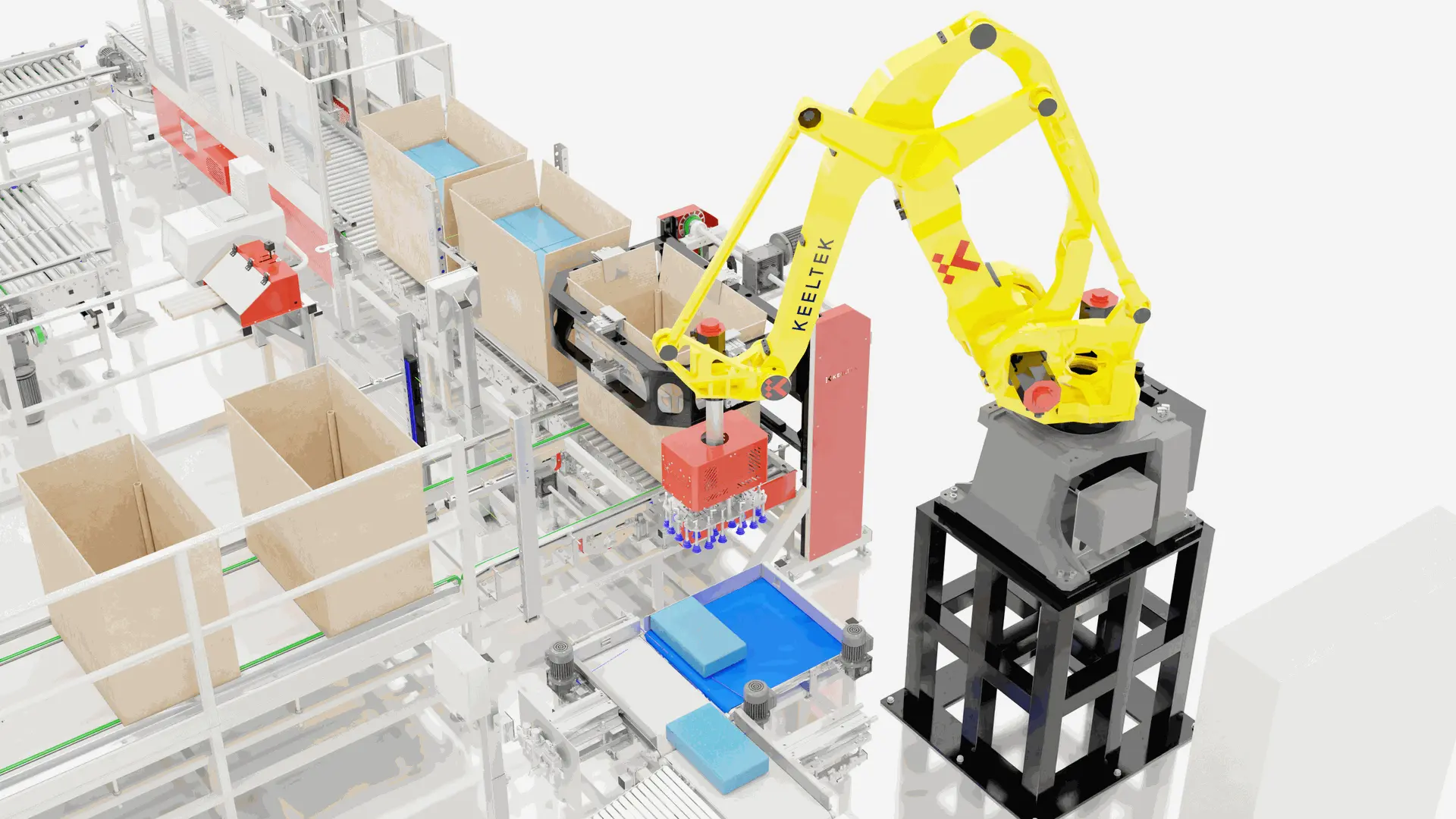

BRIOPAL/BRIODEPAL

Robotic palletizing cell

Robotic cell capable of palletizing/depalletizing any type of box, bag, and other products equipped with a robot, generally anthropomorphic with 4 to 6 axes and tools and peripherals customized for each application.

BRIOPAL/BRIODEPAL

Robotic palletizing cell

Robotic cell capable of palletizing/depalletizing any type of box, bag, and other products equipped with a robot, generally anthropomorphic with 4 to 6 axes and tools and peripherals customized for each application.

BRIOPAL/BRIODEPAL

Robotic palletizing cell

Robotic cell capable of palletizing/depalletizing any type of box, bag, and other products equipped with a robot, generally anthropomorphic with 4 to 6 axes and tools and peripherals customized for each application.

BRIOPAL/BRIODEPAL

Robotic palletizing cell

Robotic cell capable of palletizing/depalletizing any type of box, bag, and other products equipped with a robot, generally anthropomorphic with 4 to 6 axes and tools and peripherals customized for each application.

BRIOPAL/BRIODEPAL

Robotic palletizing cell

Robotic cell capable of palletizing/depalletizing any type of box, bag, and other products equipped with a robot, generally anthropomorphic with 4 to 6 axes and tools and peripherals customized for each application.

| Referencee product | Any |

| Tiles | Any tile configuration. |

| Maximum permissible load | Consult. |

| Connectivity | LAN. |

| Cadences | Consult. |

Application for tile configuration | Pallet Manager |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Features:

- Simple and intuitive creation of mosaics by the operator using proprietary software.

- Reversed layer function for improved stability.

Safety and ergonomy:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

- Custom-designed for the client

- Robot environment 100% configurable according to requirements

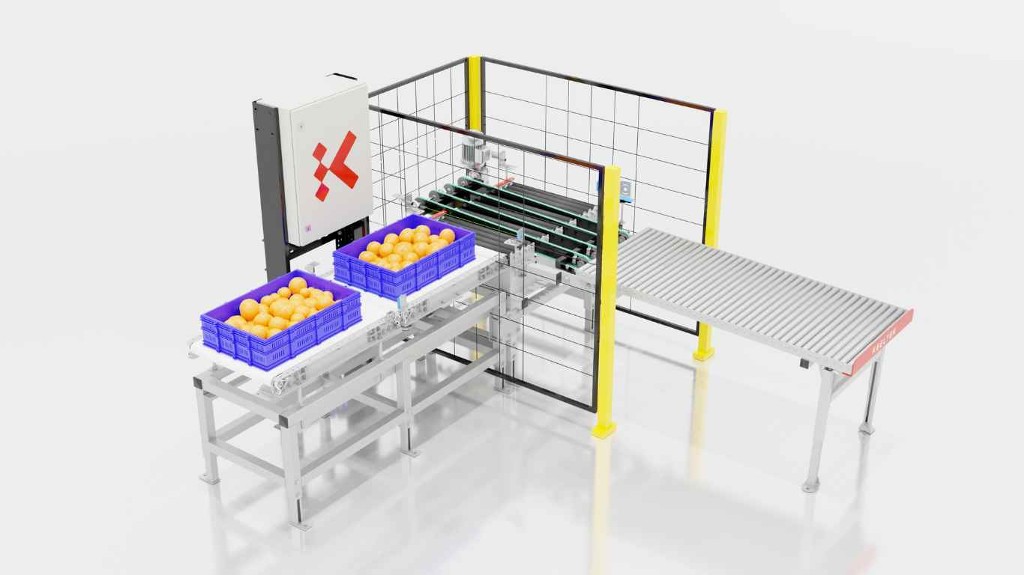

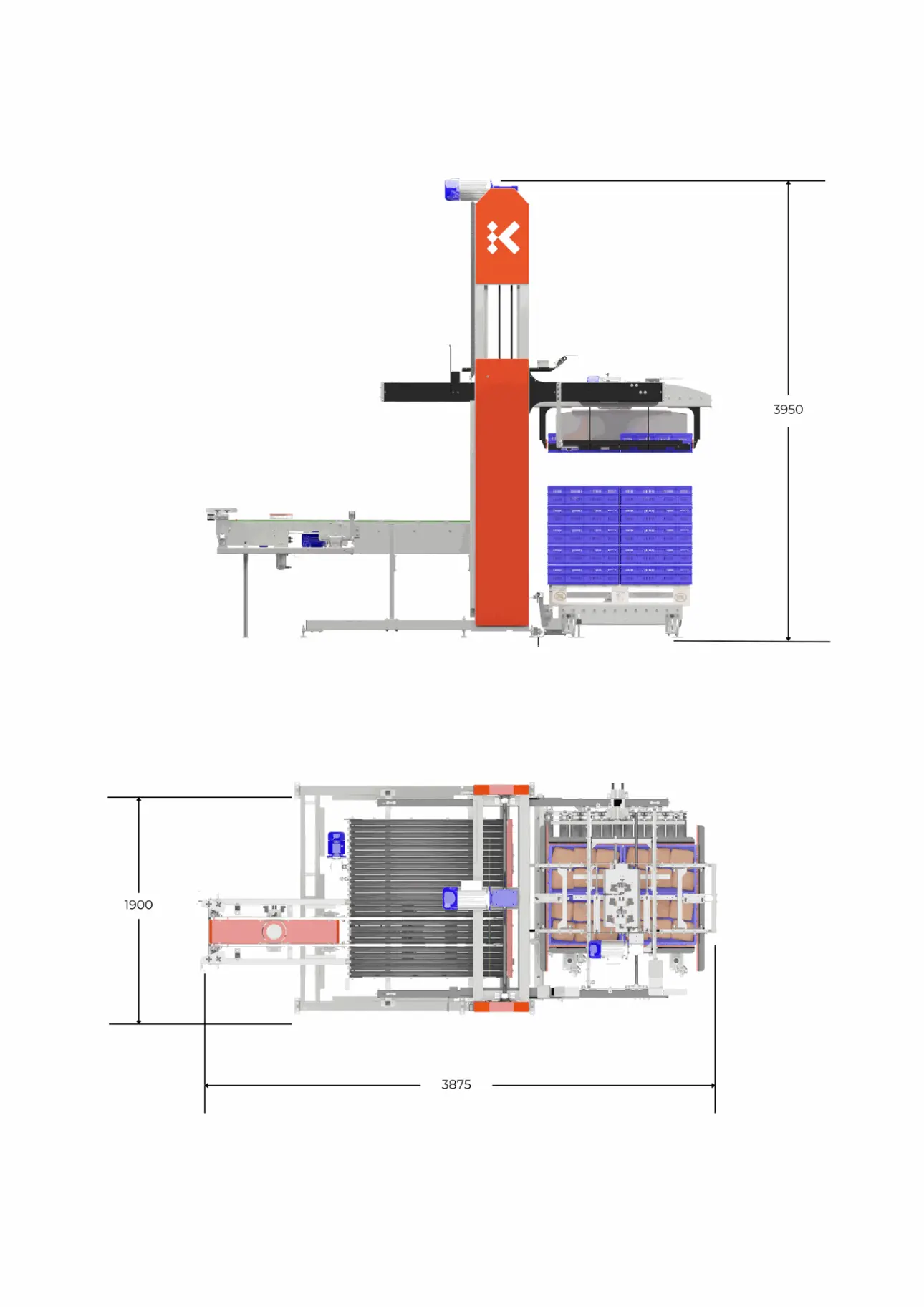

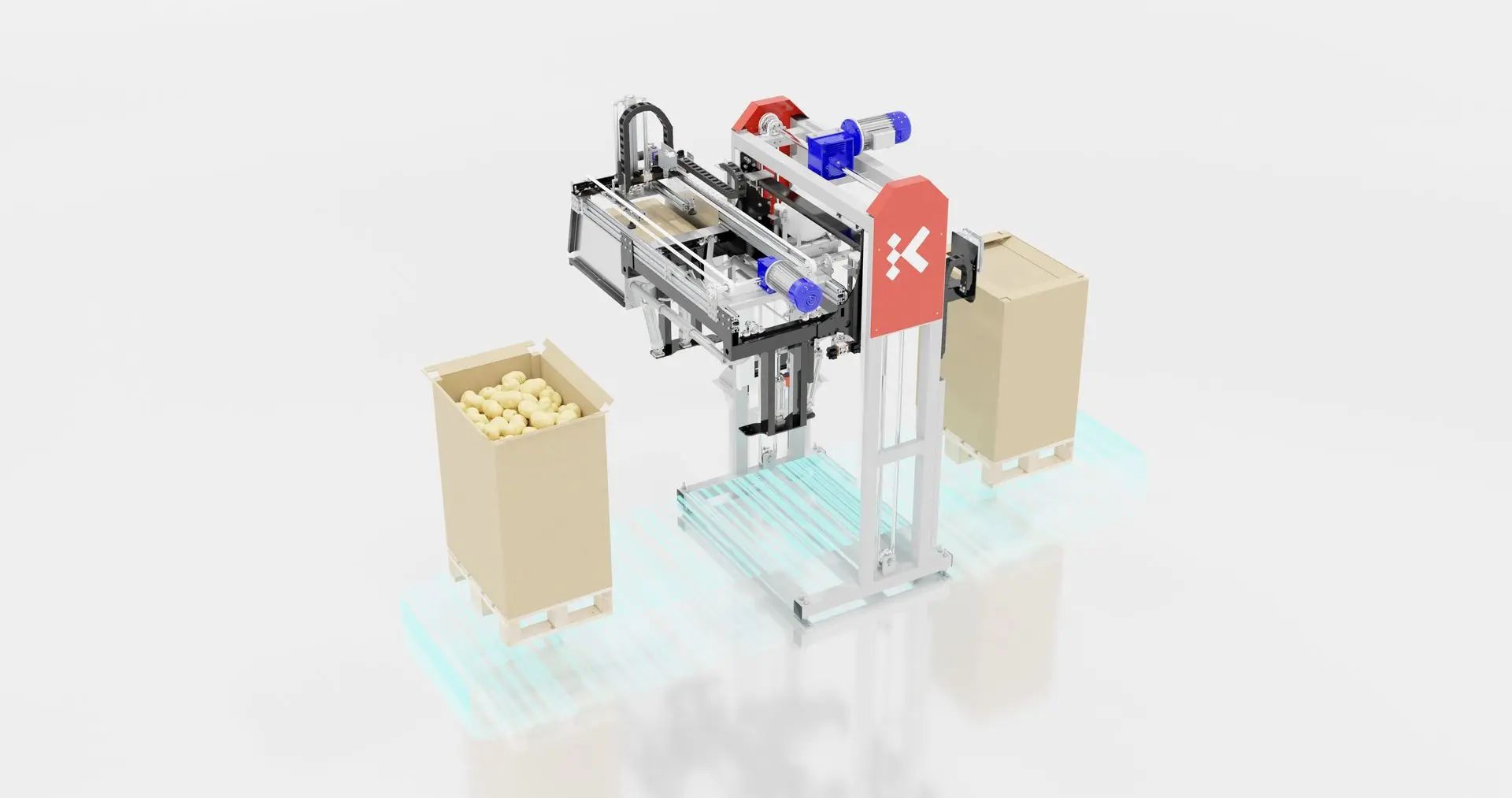

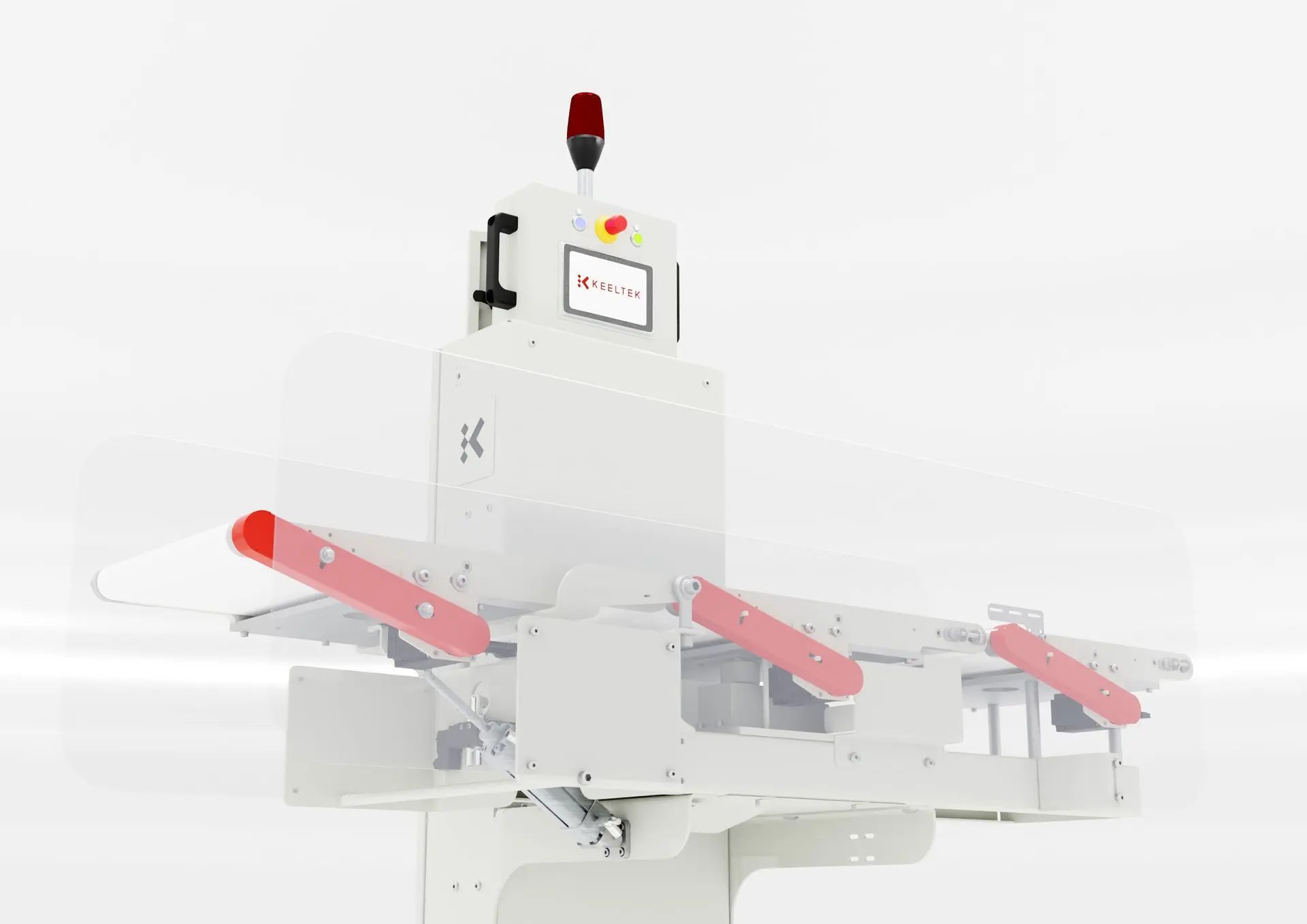

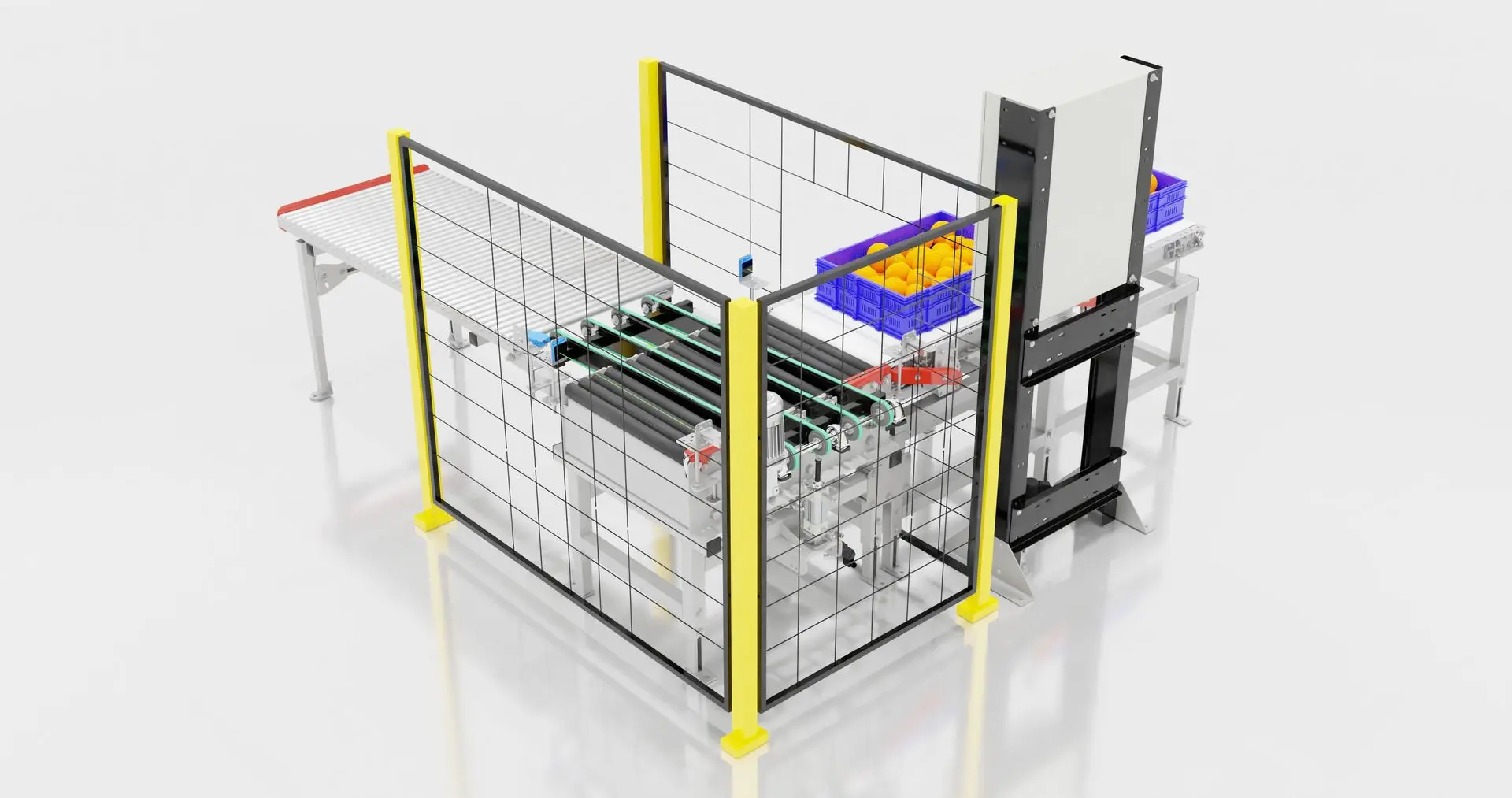

BAGPACKER (W25)

Bag packaging machine

Machine for packing and counting pre-packaged products in plastic, mesh, and recyclable and compostable paper bags, etc., in boxes weighing up to 30 kg.

BAGPACKER (W25)

Bag packaging machine

Machine for packing and counting pre-packaged products in plastic, mesh, and recyclable and compostable paper bags, etc., in boxes weighing up to 30 kg.

BAGPACKER (W25)

Bag packaging machine

Machine for packing and counting pre-packaged products in plastic, mesh, and recyclable and compostable paper bags, etc., in boxes weighing up to 30 kg.

BAGPACKER (W25)

Bag packaging machine

Machine for packing and counting pre-packaged products in plastic, mesh, and recyclable and compostable paper bags, etc., in boxes weighing up to 30 kg.

BAGPACKER (W25)

Bag packaging machine

Machine for packing and counting pre-packaged products in plastic, mesh, and recyclable and compostable paper bags, etc., in boxes weighing up to 30 kg.

BAGPACKER (W25)

Bag packaging machine

Machine for packing and counting pre-packaged products in plastic, mesh, and recyclable and compostable paper bags, etc., in boxes weighing up to 30 kg.

Configurable box and product entry direction

| Reference product | Boxes measuring 600 mm x 400 mm – Bags up to 5 kg |

| Maximum permissible load | Up to 50 kg |

|

Connectivity

|

LAN |

| Cadences | Up to 90 units per minute. |

- Conveyor circuit for upstream product management.

- Automatic box dispenser.

- Stacking or palletizing full boxes.

- Kit for accommodating boxes measuring 400 mm x 300 mm.

- KTS, remote assistance.

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Features:

- Simple and intuitive creation of mosaics by the operator using proprietary software.

- Reversed layer function for improved stability.

Safety and ergonomy:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed by laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

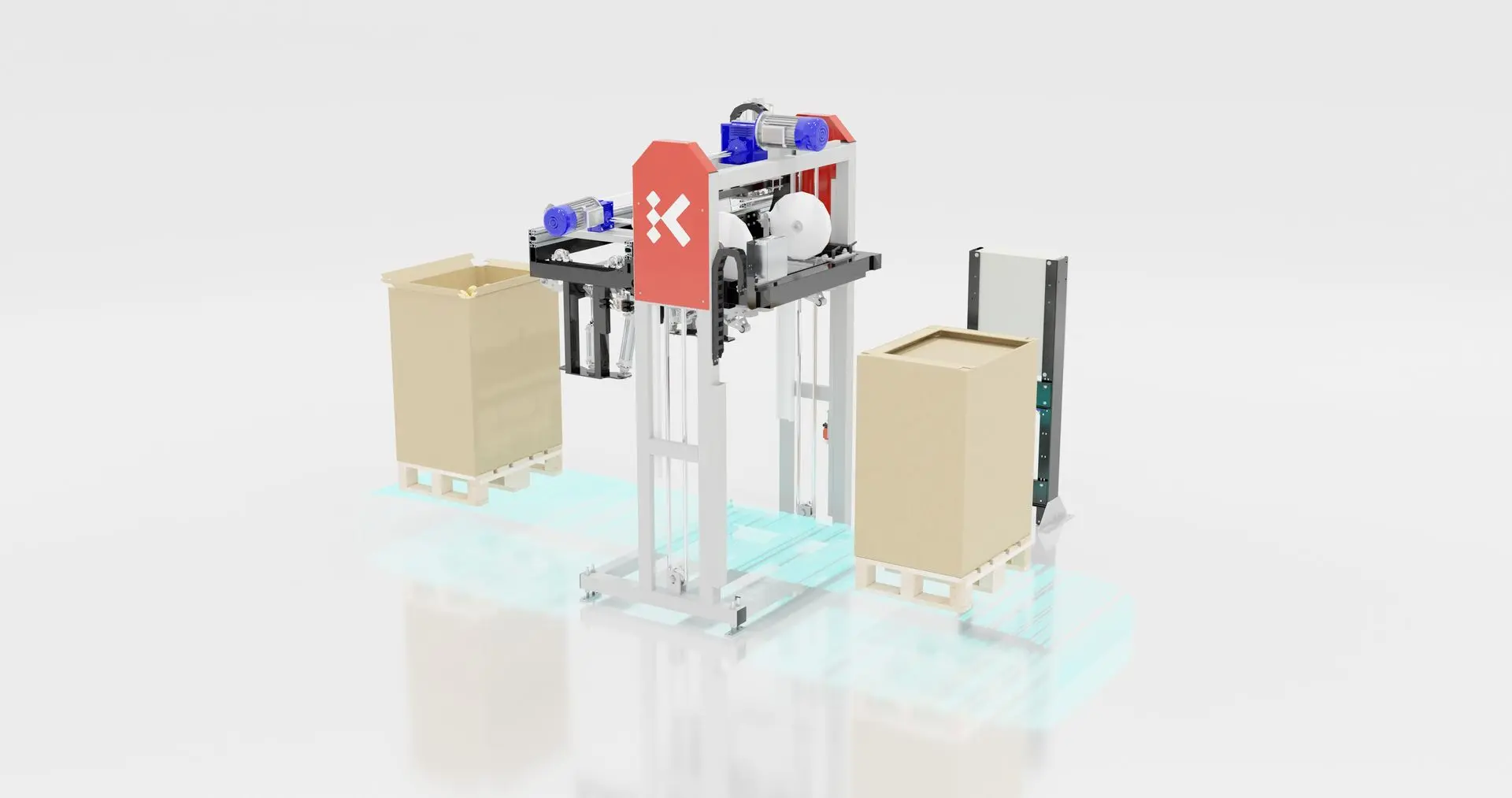

BAGPACKER W250

Bag-into-box packing machine

Machine for packing and counting pre-packaged products in plastic, mesh, and recyclable and compostable paper bags, etc., in boxes weighing up to 250 kg.

BAGPACKER W250

Bag-into-box packing machine

Machine for packing and counting pre-packaged products in plastic, mesh, and recyclable and compostable paper bags, etc., in boxes weighing up to 250 kg.

BAGPACKER W250

Bag-into-box packing machine

Machine for packing and counting pre-packaged products in plastic, mesh, and recyclable and compostable paper bags, etc., in boxes weighing up to 250 kg.

BAGPACKER W250

Bag-into-box packing machine

Machine for packing and counting pre-packaged products in plastic, mesh, and recyclable and compostable paper bags, etc., in boxes weighing up to 250 kg.

BAGPACKER W250

Bag-into-box packing machine

Machine for packing and counting pre-packaged products in plastic, mesh, and recyclable and compostable paper bags, etc., in boxes weighing up to 250 kg.

| Reference product | Boxes measuring 800 mm x 600 mm – Bags up to 10 kg |

| Tiles | |

| Maximum permissible load | |

|

Connectivity

|

LAN |

| Cadences | up to 60 units per minute. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Features:

- Simple and intuitive creation of mosaics by the operator using proprietary software.

- Reversed layer function for improved stability.

Safety and ergonomy:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed by laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Conveyor circuit for upstream product management.

- Folding and sealing of boxes. (FOLDBOX)

- Strapping and stacking the boxes.

- KTS, remote assistance.

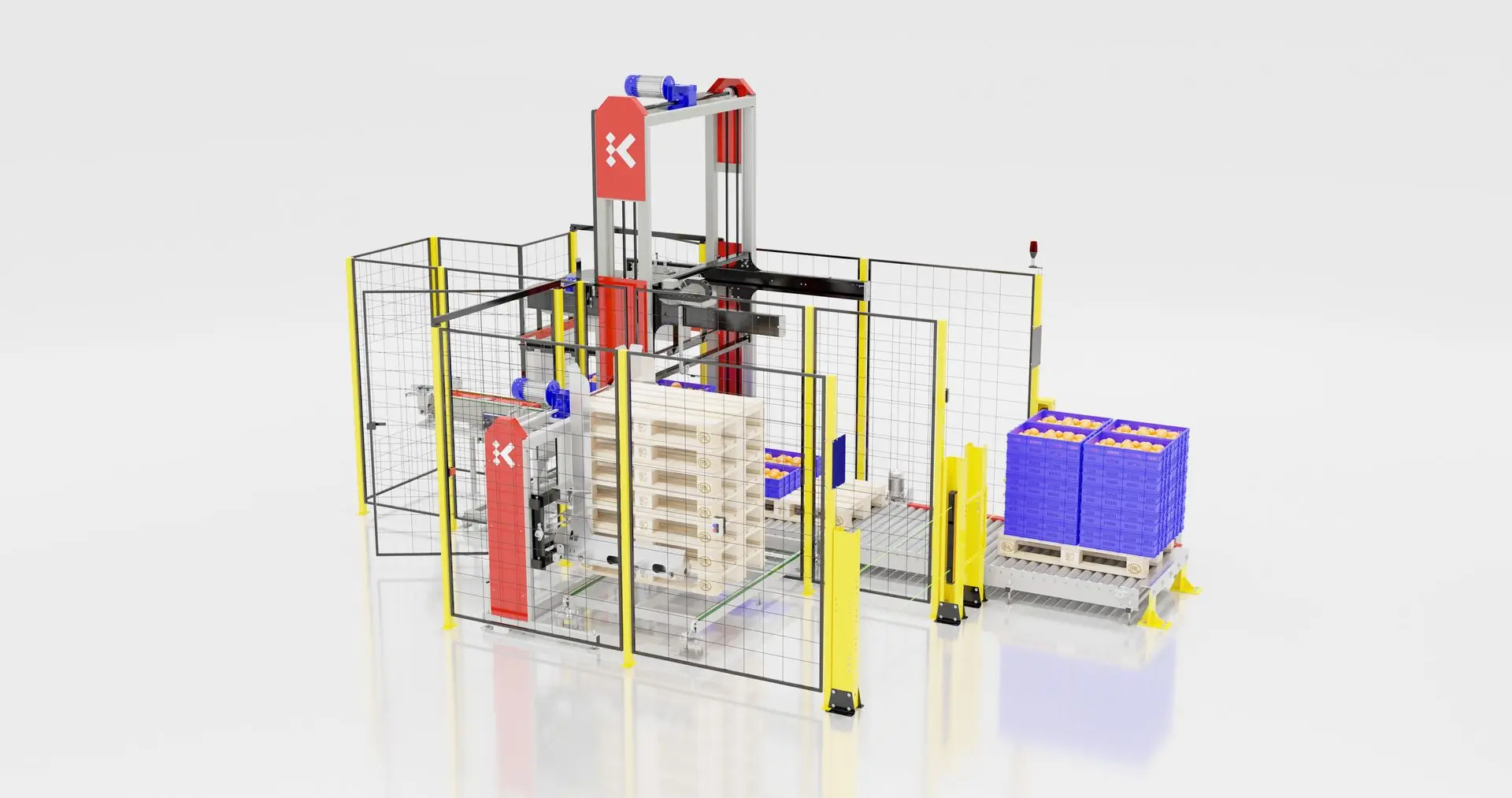

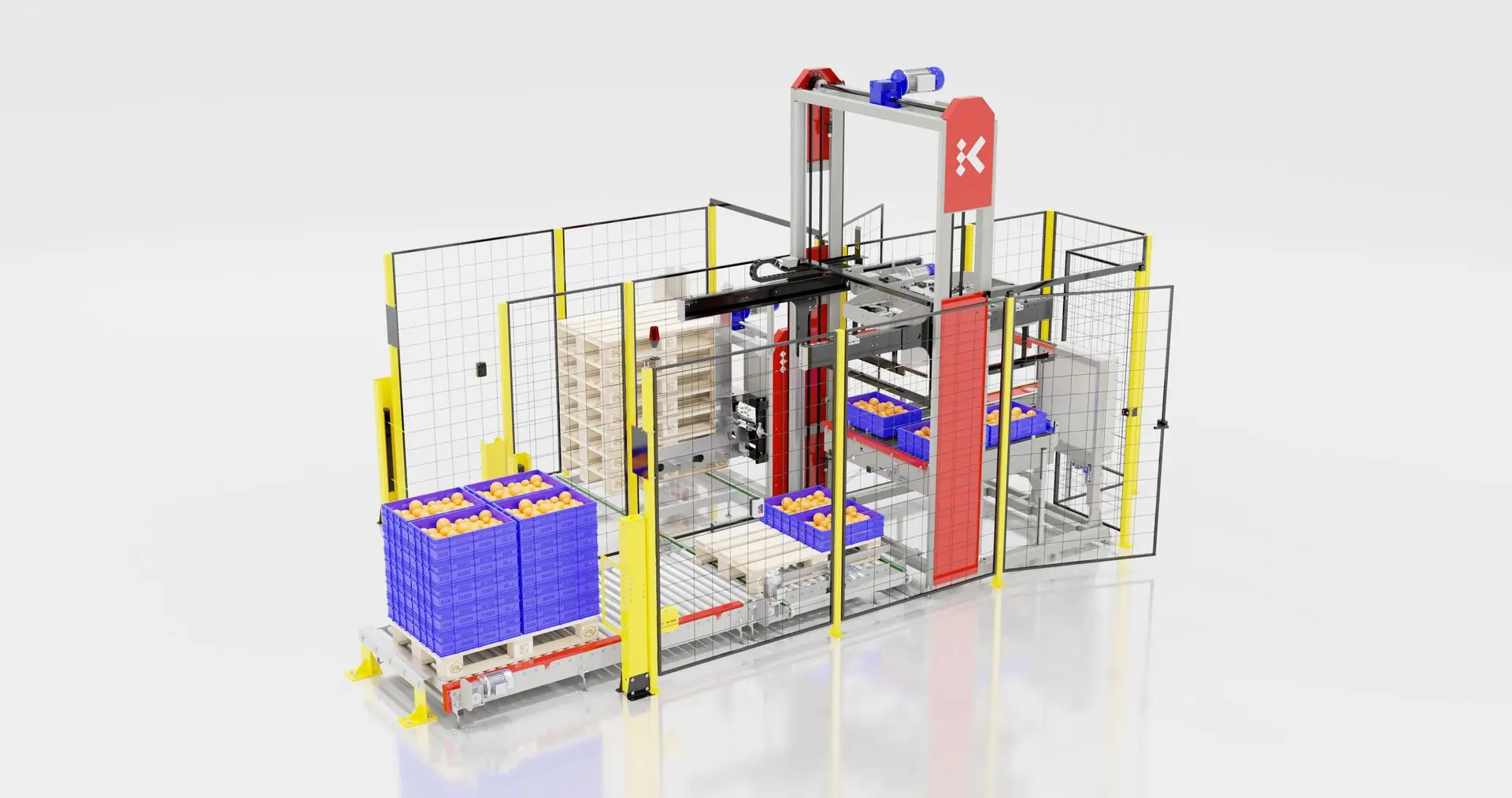

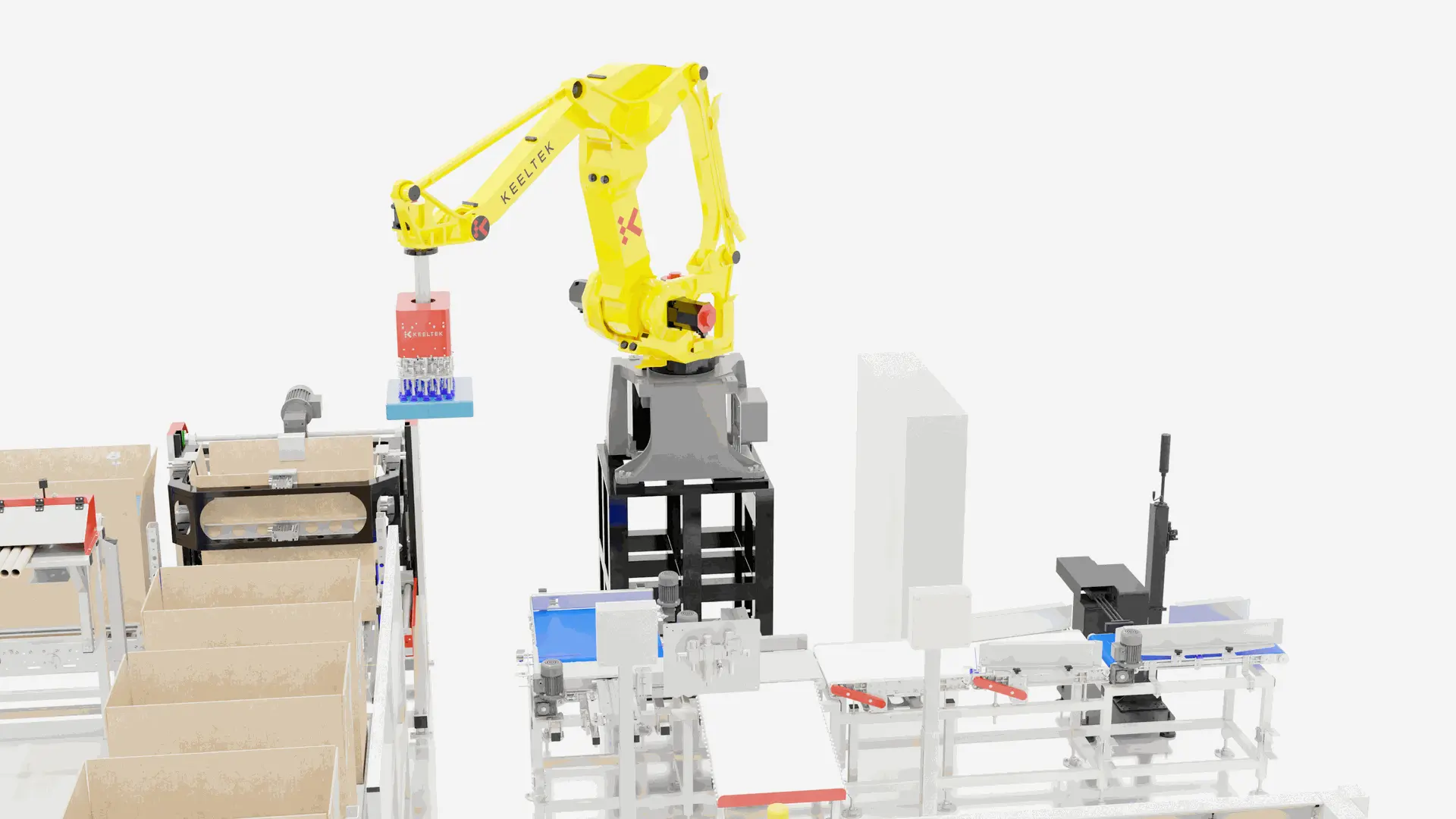

BRIOPACKER

Robotic packing cell

Robotic cell for packing or filling multiple containers with products of any kind

BRIOPACKER

Robotic packing cell

Robotic cell for packing or filling multiple containers with products of any kind

BRIOPACKER

Robotic packing cell

Robotic cell for packing or filling multiple containers with products of any kind

BRIOPACKER

Robotic packing cell

Robotic cell for packing or filling multiple containers with products of any kind

BRIOPACKER

Robotic packing cell

Robotic cell for packing or filling multiple containers with products of any kind

| Reference product | Depending on application. (Boxes, bins, blister packs, bags, nets, packages, etc.) |

| Maximum permissible load | Consult. |

| Connectivity | LAN. |

| Cadences | Up to 10 pickings/minute |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

- Different options depending on application.

- KTS, remote assistance.

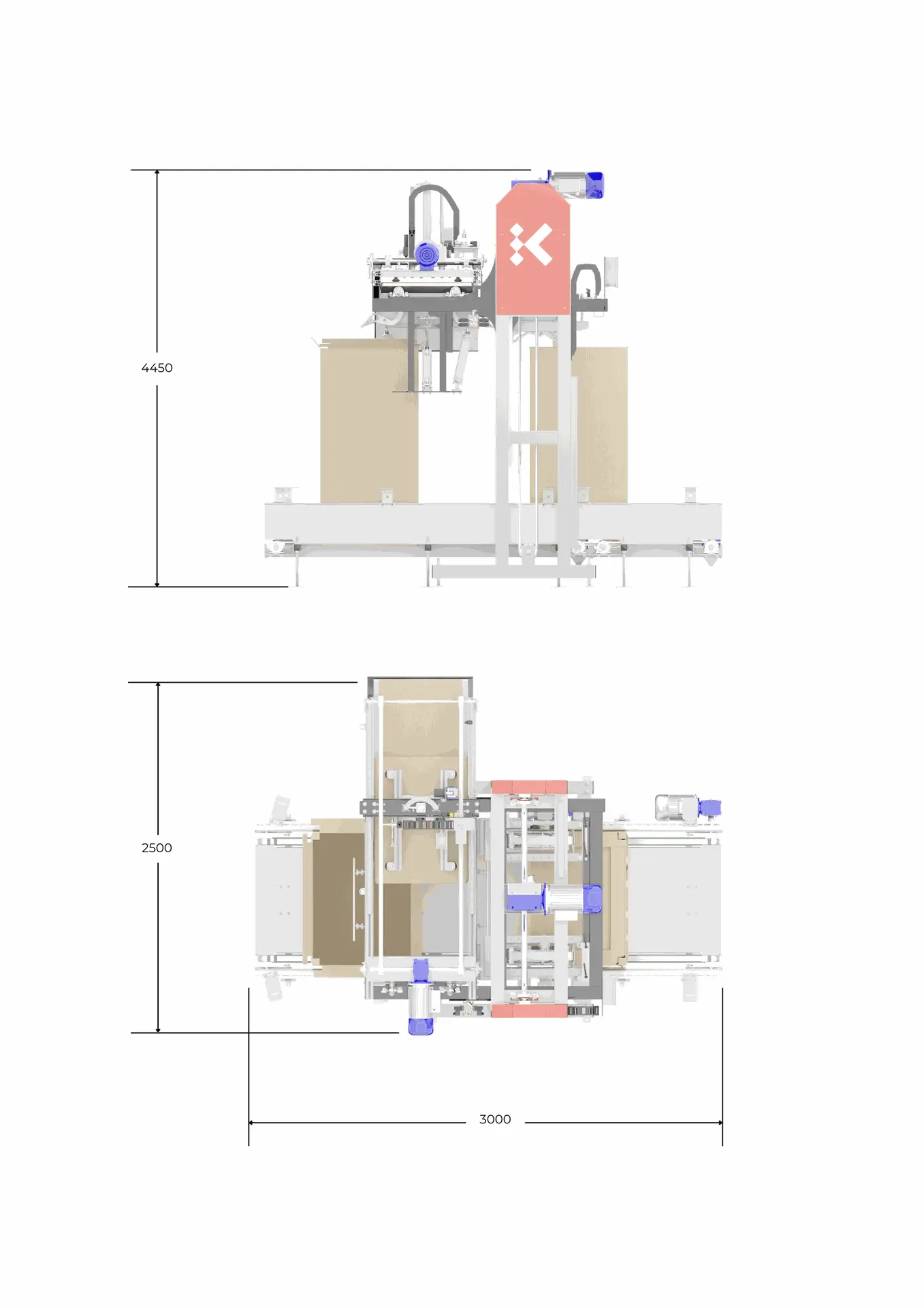

FLAPFOLD

Flap folding and sealing station

Folding and sealing line for flaps on cardboard boxes filled with product.

FLAPFOLD

Flap folding and sealing station

Folding and sealing line for flaps on cardboard boxes filled with product.

FLAPFOLD

Flap folding and sealing station

Folding and sealing line for flaps on cardboard boxes filled with product.

FLAPFOLD

Flap folding and sealing station

Folding and sealing line for flaps on cardboard boxes filled with product.

FLAPFOLD

Flap folding and sealing station

Folding and sealing line for flaps on cardboard boxes filled with product.

| Reference product | Boxes measuring 600x800 and heights ranging from 450mm to 1100mm. |

| Application |

800x600 cardboard semi-box filling line with nets for potatoes, citrus fruits, nuts, rice packages, napkins, etc. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Safety and ergonomy:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed by laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Can be integrated into our Overpack Plus line.

- Possibility of adding an inner cover to the box before folding the flaps.

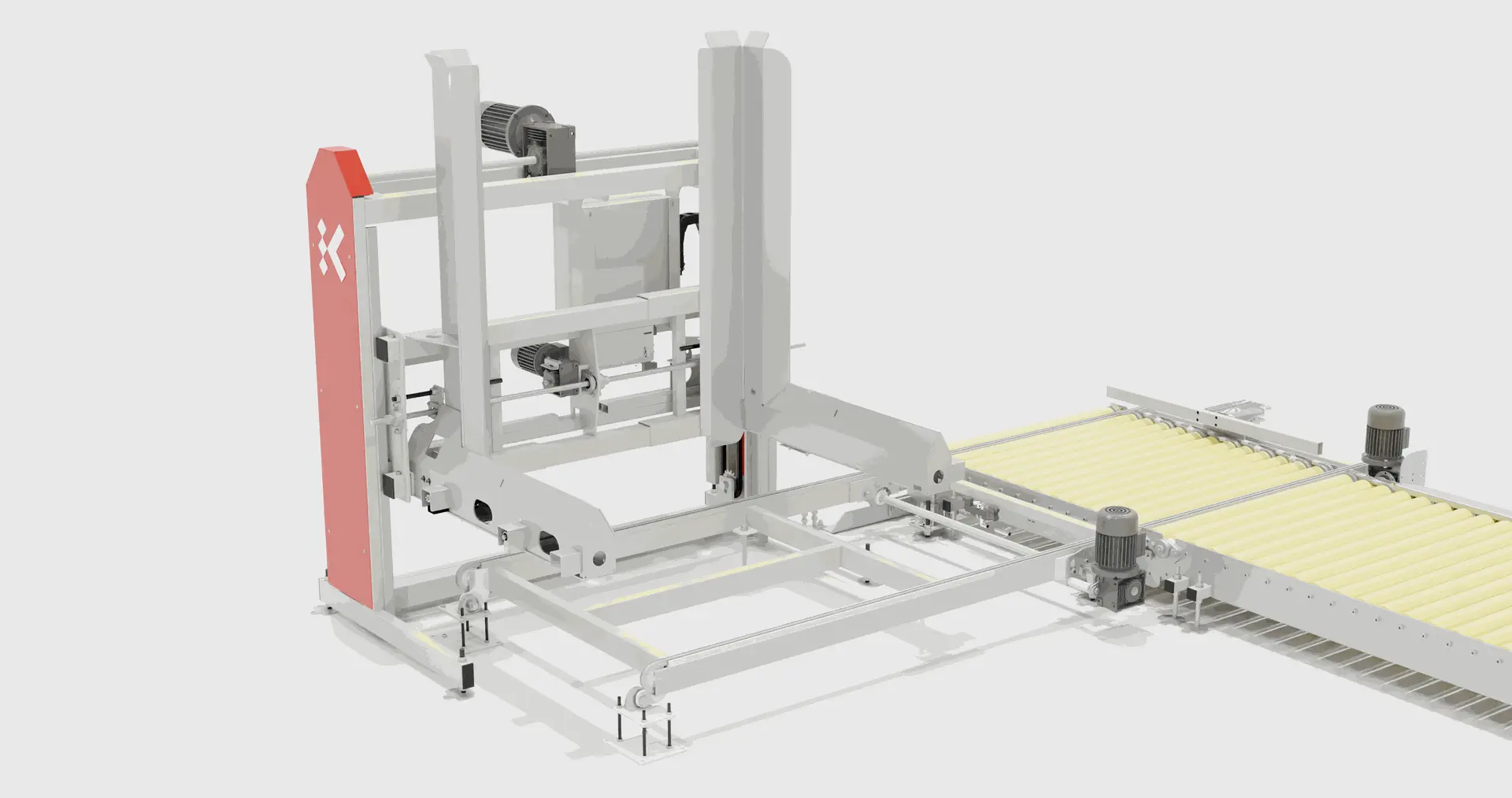

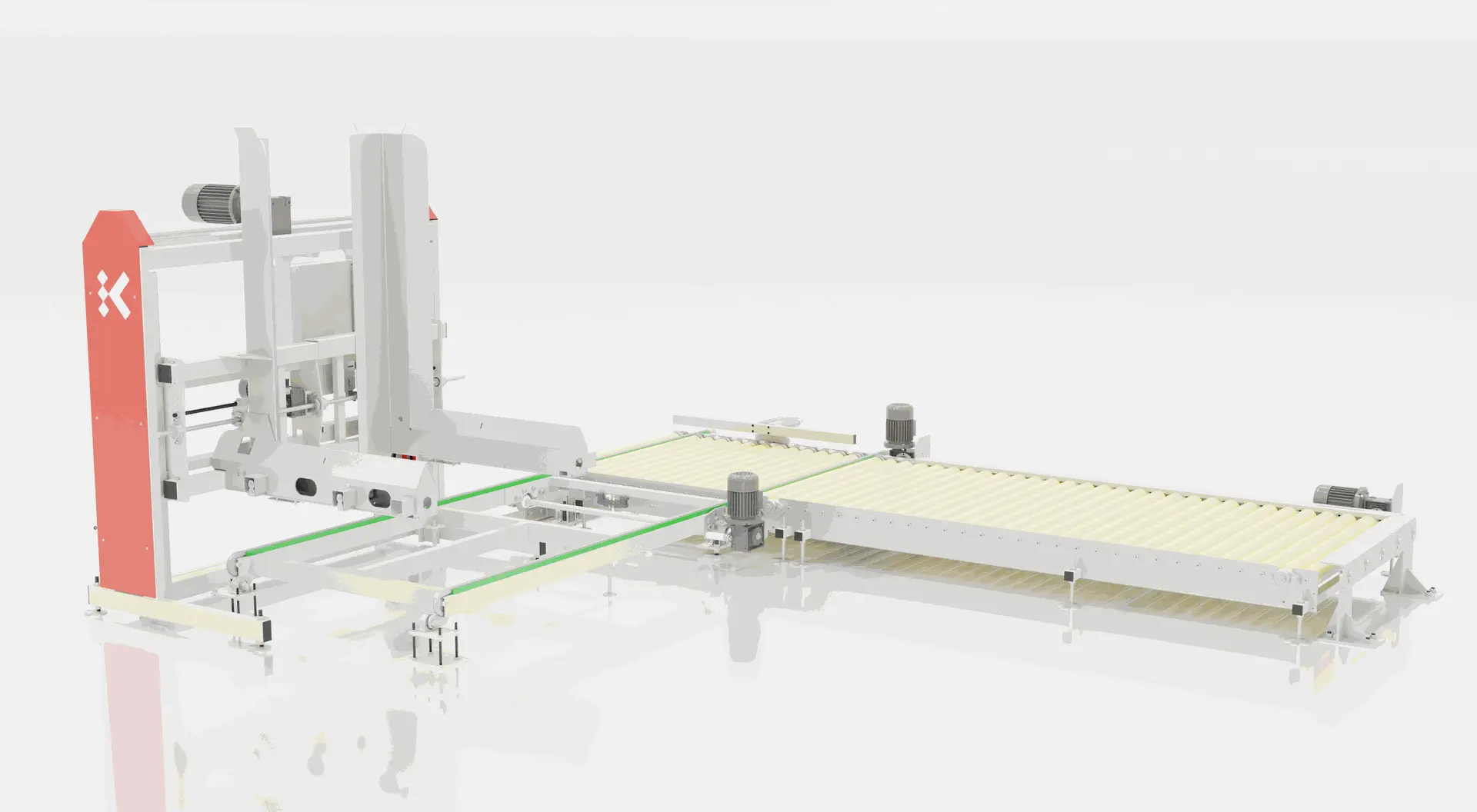

DISPALLET

Automatic pallet destacker

Automatic pallet dispenser for production line. The system is fed by a stack of pallets.

DISPALLET

Automatic pallet destacker

Automatic pallet dispenser for production line. The system is fed by a stack of pallets.

DISPALLET

Automatic pallet destacker

Automatic pallet dispenser for production line. The system is fed by a stack of pallets.

DISPALLET

Automatic pallet destacker

Automatic pallet dispenser for production line. The system is fed by a stack of pallets.

DISPALLET

Automatic pallet destacker

Automatic pallet dispenser for production line. The system is fed by a stack of pallets.

DISPALLET

Automatic pallet destacker

Automatic pallet dispenser for production line. The system is fed by a stack of pallets.

DISPALLET

Automatic pallet destacker

Automatic pallet dispenser for production line. The system is fed by a stack of pallets.

DISPALLET

Automatic pallet destacker

Automatic pallet dispenser for production line. The system is fed by a stack of pallets.

| Reference product | Pallets of different sizes (length, width, and height). |

| Compatibility |

Compatible with any palletizing system. |

Storage capacity | Consult. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Safety and ergonomy:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed by laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Automatic adjustment to different pallet widths.

- Delivery to laminator, palletizer, etc.

DISPALLET + COVERFILM

Pallet destacker with film cover

Pallet dispenser for line. The system is fed by a stack of pallets. Includes plastic film applicator on the pallet.

DISPALLET + COVERFILM

Pallet destacker with film cover

Pallet dispenser for line. The system is fed by a stack of pallets. Includes plastic film applicator on the pallet.

DISPALLET + COVERFILM

Pallet destacker with film cover

Pallet dispenser for line. The system is fed by a stack of pallets. Includes plastic film applicator on the pallet.

DISPALLET + COVERFILM

Pallet destacker with film cover

Pallet dispenser for line. The system is fed by a stack of pallets. Includes plastic film applicator on the pallet.

DISPALLET + COVERFILM

Pallet destacker with film cover

Pallet dispenser for line. The system is fed by a stack of pallets. Includes plastic film applicator on the pallet.

DISPALLET + COVERFILM

Pallet destacker with film cover

Pallet dispenser for line. The system is fed by a stack of pallets. Includes plastic film applicator on the pallet.

| Reference product | Pallets of different sizes (length, width, and height). |

| Compatibility |

Designed to work in line with DISPALLET. |

|

Integration |

It can be inserted into any existing line on the pallet passage. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Safety and ergonomy:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed by laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

-

Paper or other types of materials supplied in rolls can be applied.

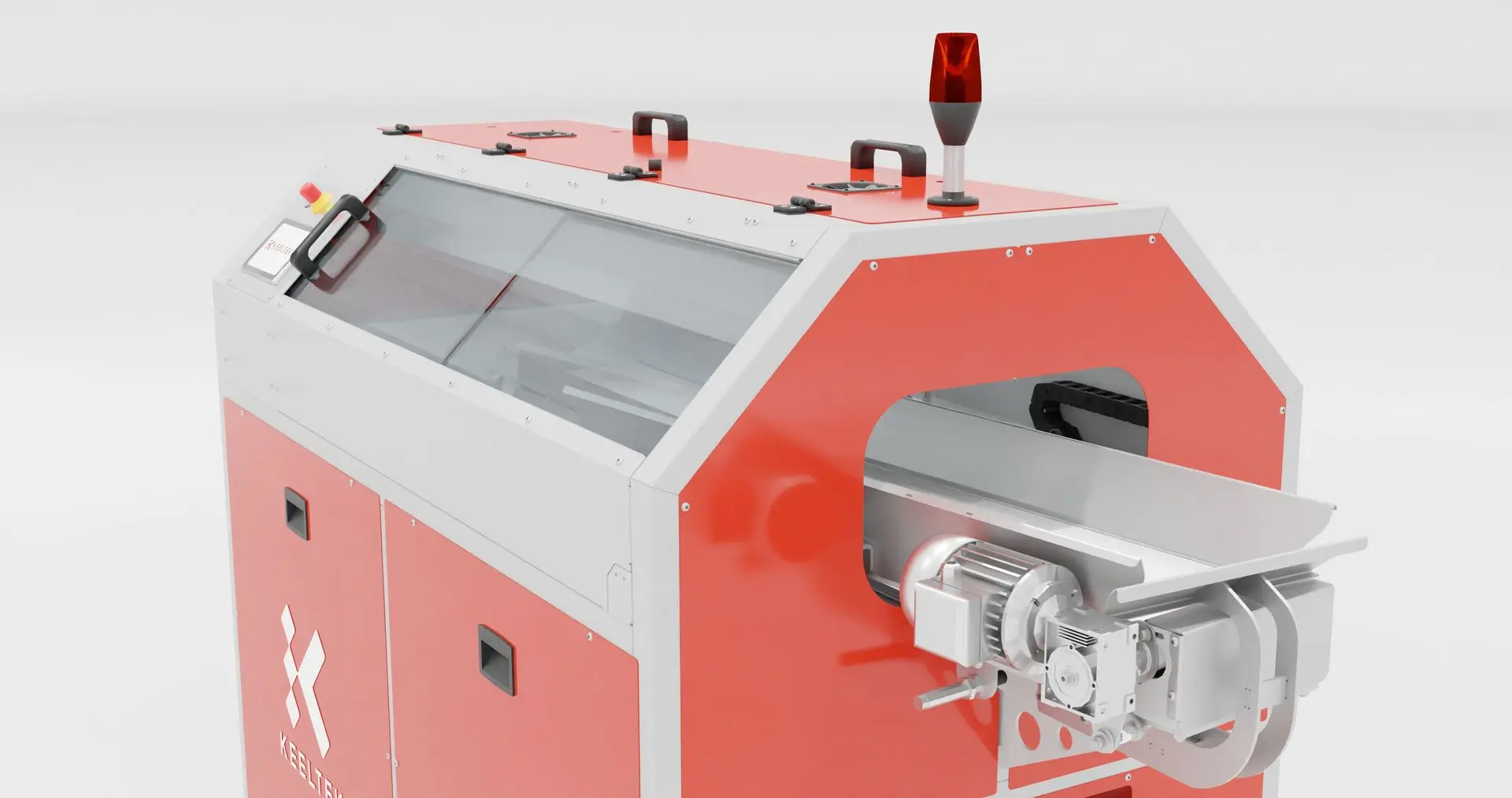

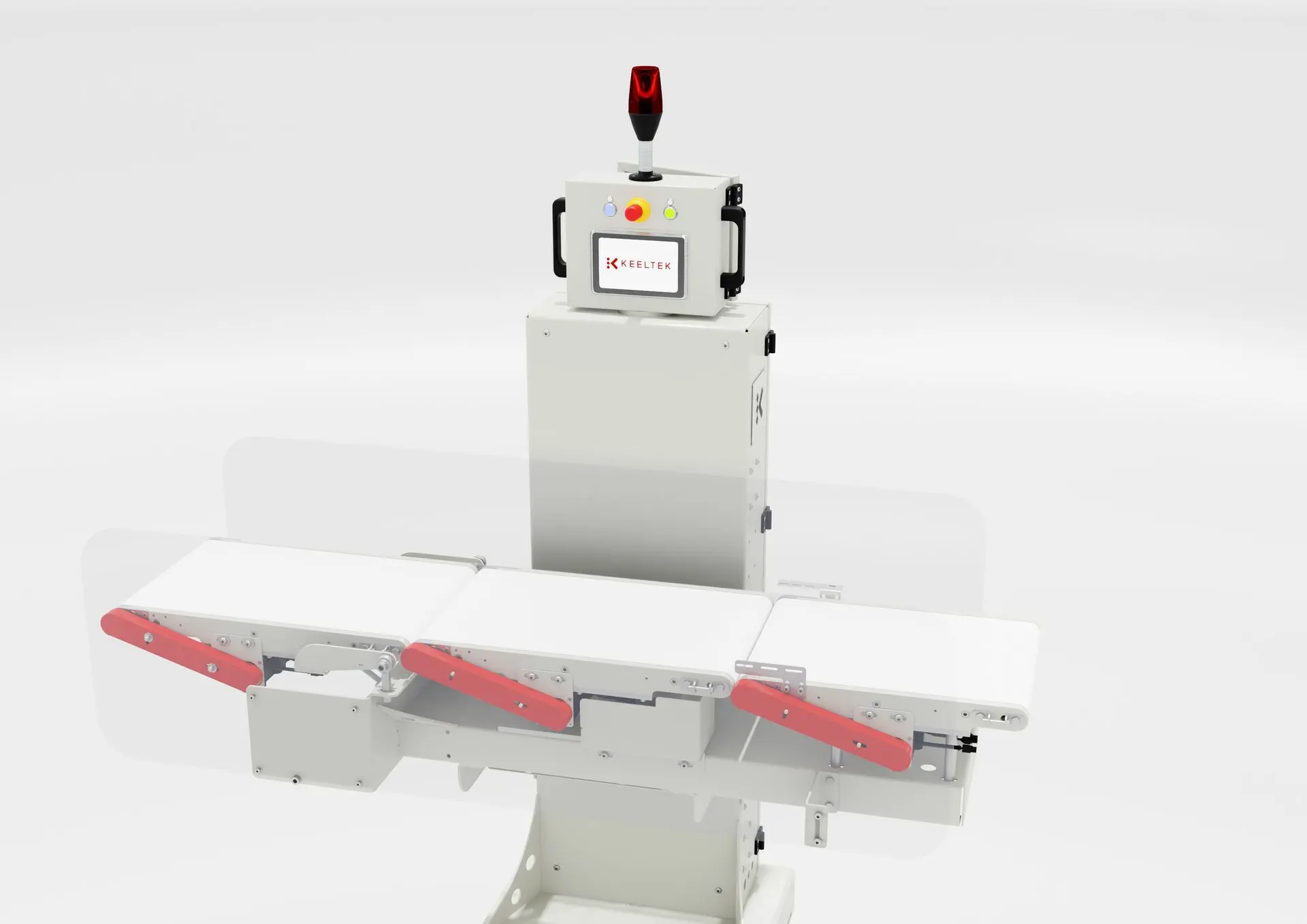

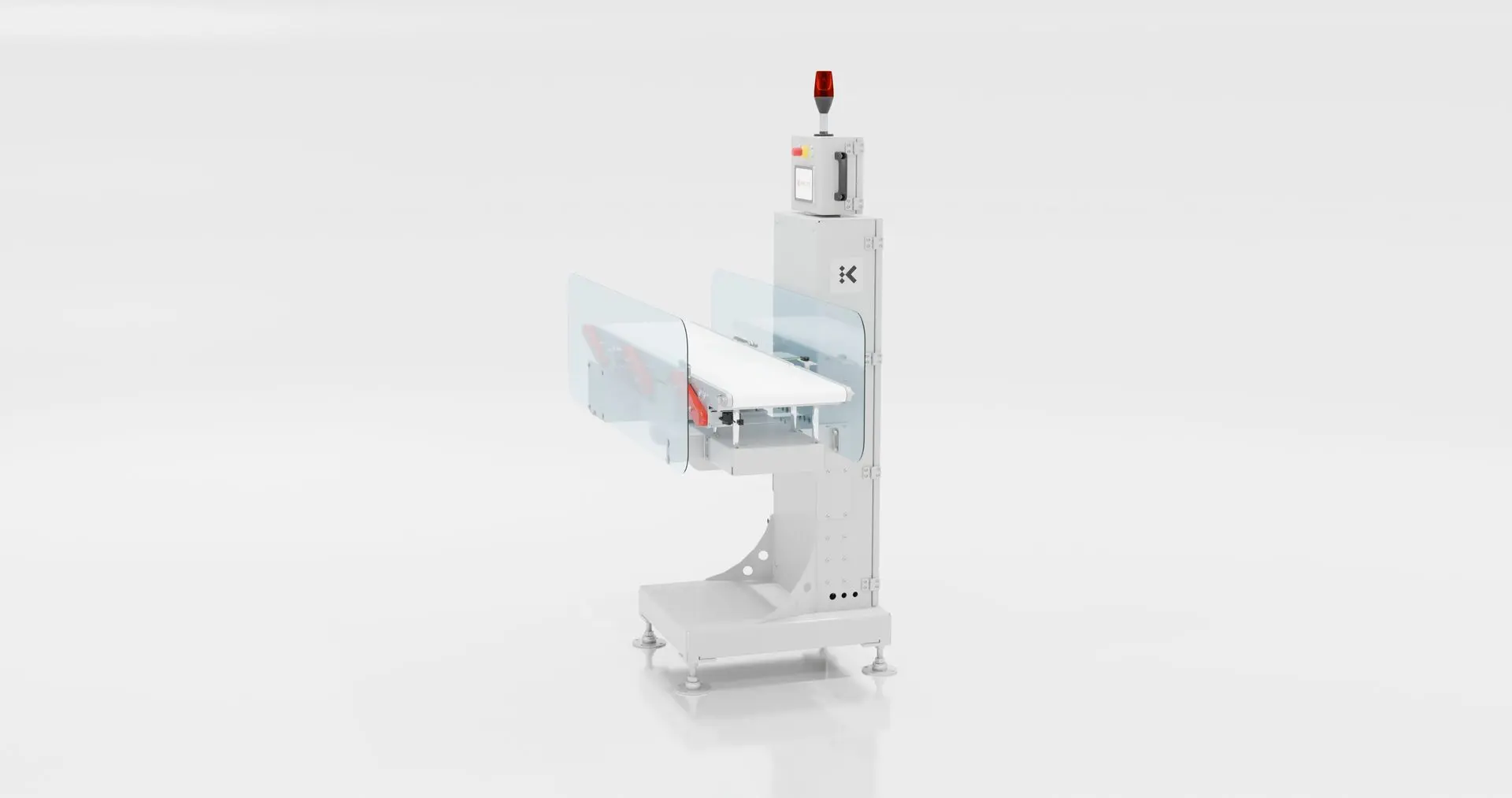

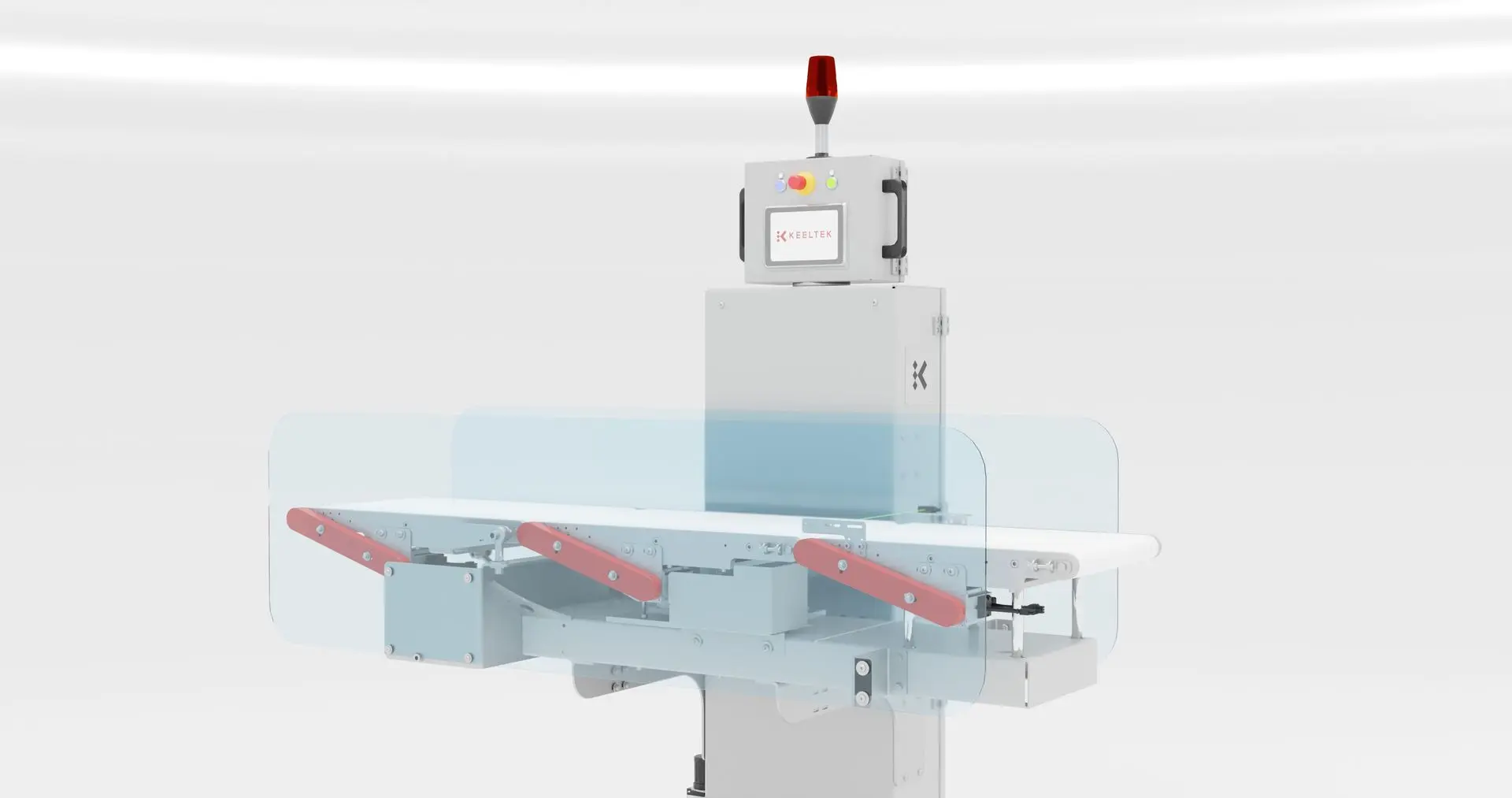

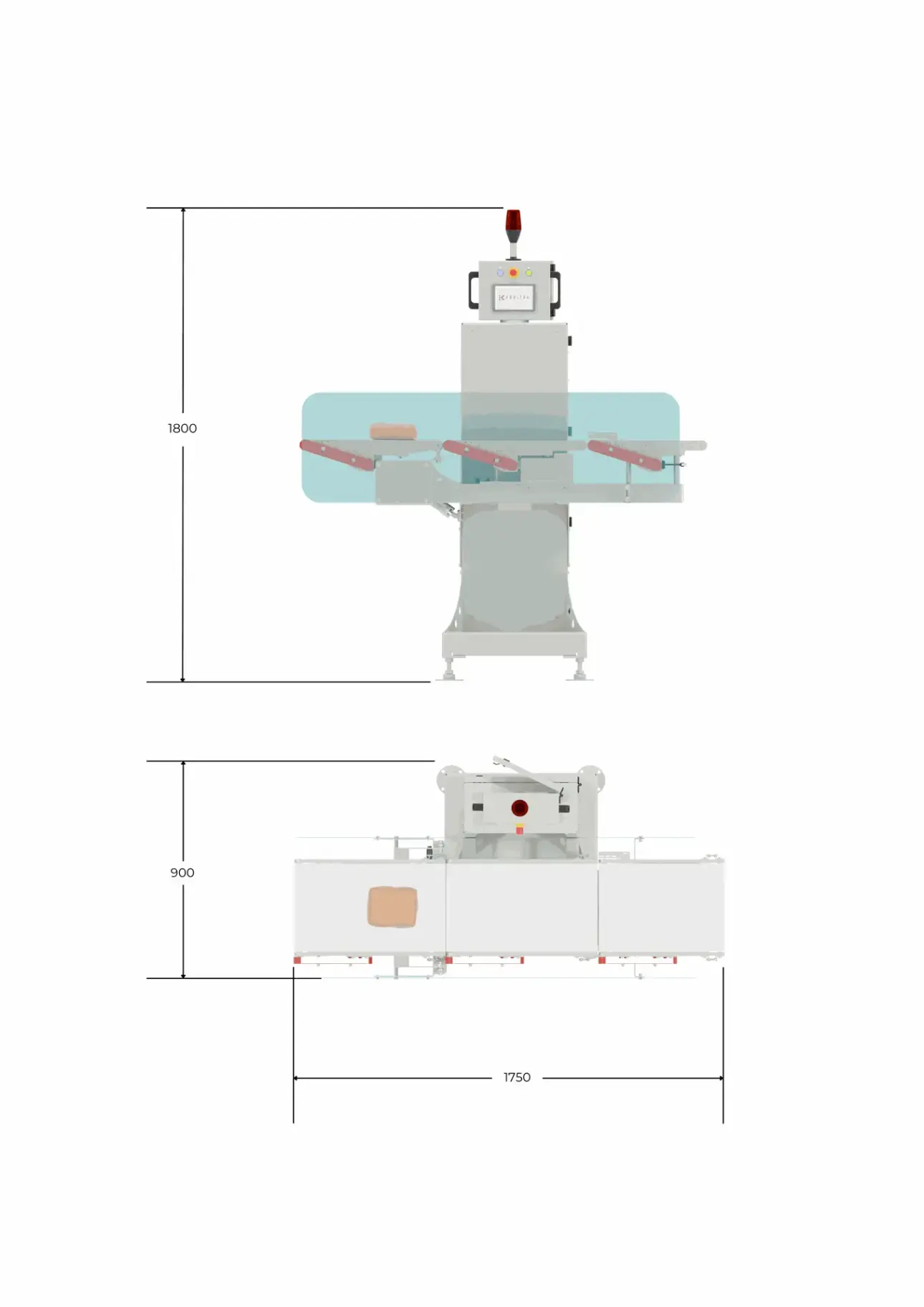

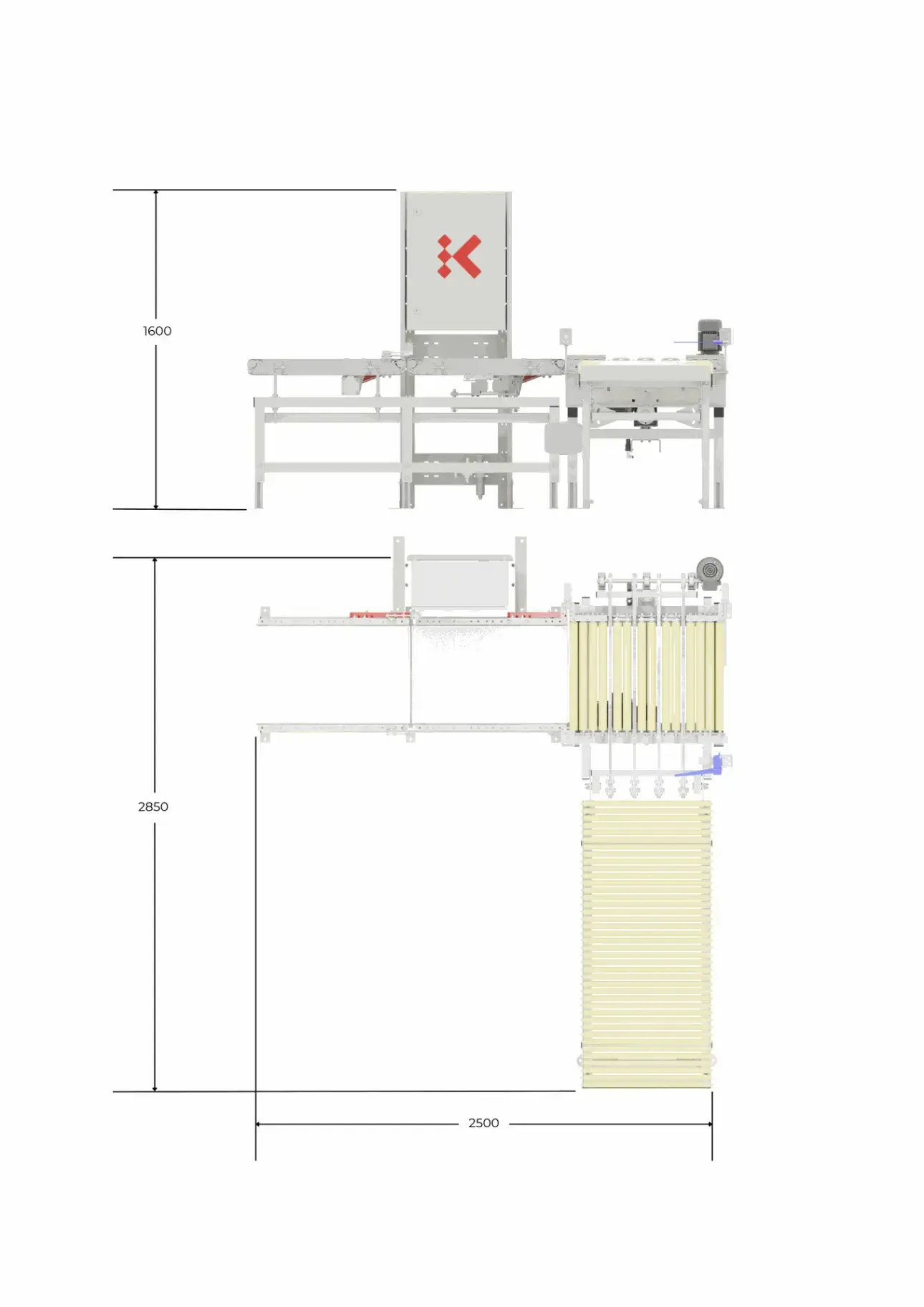

WEIGHTSENT DW5E

Weight discriminator up to 5 kg

Automatic dynamic weight discriminator, specially designed for small bags and boxes. Includes diverter for rejection.

WEIGHTSENT DW5E

Weight discriminator up to 5 kg

Automatic dynamic weight discriminator, specially designed for small bags and boxes. Includes diverter for rejection.

WEIGHTSENT DW5E

Weight discriminator up to 5 kg

Automatic dynamic weight discriminator, specially designed for small bags and boxes. Includes diverter for rejection.

WEIGHTSENT DW5E

Weight discriminator up to 5 kg

Automatic dynamic weight discriminator, specially designed for small bags and boxes. Includes diverter for rejection.

WEIGHTSENT DW5E

Weight discriminator up to 5 kg

Automatic dynamic weight discriminator, specially designed for small bags and boxes. Includes diverter for rejection.

WEIGHTSENT DW5E

Weight discriminator up to 5 kg

Automatic dynamic weight discriminator, specially designed for small bags and boxes. Includes diverter for rejection.

WEIGHTSENT DW5E

Weight discriminator up to 5 kg

Automatic dynamic weight discriminator, specially designed for small bags and boxes. Includes diverter for rejection.

WEIGHTSENT DW5E

Weight discriminator up to 5 kg

Automatic dynamic weight discriminator, specially designed for small bags and boxes. Includes diverter for rejection.

WEIGHTSENT DW5E

Weight discriminator up to 5 kg

Automatic dynamic weight discriminator, specially designed for small bags and boxes. Includes diverter for rejection.

WEIGHTSENT DW5E

Weight discriminator up to 5 kg

Automatic dynamic weight discriminator, specially designed for small bags and boxes. Includes diverter for rejection.

| Reference product | Any product weighing between 50 g and 5 kg. |

| Cadences |

Up to 120 units per minute. |

| Resolution | +- 1 g. |

|

Accuracy |

+- 5 g. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Handling:

- Compact machine that can be easily integrated into the production line

Regulations:

- Ability to work in food environments.

- Batch control.

- Statistic.

- LAN connectivity.

- Integration: SCADA, ERP.

WEIGHTSENT DW25E

Weight discriminator up to 25 kg

Automatic dynamic weight discriminator, specially designed for medium-sized boxes. Includes diverter for rejection.

WEIGHTSENT DW25E

Weight discriminator up to 25 kg

Automatic dynamic weight discriminator, specially designed for medium-sized boxes. Includes diverter for rejection.

WEIGHTSENT DW25E

Weight discriminator up to 25 kg

Automatic dynamic weight discriminator, specially designed for medium-sized boxes. Includes diverter for rejection.

WEIGHTSENT DW25E

Weight discriminator up to 25 kg

Automatic dynamic weight discriminator, specially designed for medium-sized boxes. Includes diverter for rejection.

WEIGHTSENT DW25E

Weight discriminator up to 25 kg

Automatic dynamic weight discriminator, specially designed for medium-sized boxes. Includes diverter for rejection.

| Reference product | Boxes up to 25 kg. |

| Cadences |

Up to 15 units/minute. |

| Resolution |

+- 15 g. |

|

Accuracy |

+- 20 g. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Handling:

- Compact machine that can be easily integrated into the production line.

Regulations:

- Ability to work in food environments.

- Data recording in file.

- Batch control.

- Statistic.

- LAN connectivity.

- Integration: SCADA, ERP.

WEIGHTSENT DW50E

Weight discriminator for heavy loads

Automatic dynamic weight discriminator, specially designed for pallets and large loads. Includes diverter for rejection.

WEIGHTSENT DW50E

Weight discriminator for heavy loads

Automatic dynamic weight discriminator, specially designed for pallets and large loads. Includes diverter for rejection.

WEIGHTSENT DW50E

Weight discriminator for heavy loads

Automatic dynamic weight discriminator, specially designed for pallets and large loads. Includes diverter for rejection.

WEIGHTSENT DW50E

Weight discriminator for heavy loads

Automatic dynamic weight discriminator, specially designed for pallets and large loads. Includes diverter for rejection.

WEIGHTSENT DW50E

Weight discriminator for heavy loads

Automatic dynamic weight discriminator, specially designed for pallets and large loads. Includes diverter for rejection.

| Reference product | Pallets/boxes up to 1500 kg. |

| Cadences |

Consult. |

| Resolution |

+- 15 g. |

|

Accuracy |

+- 20 g. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Handling:

- Compact machine that can be easily integrated into the production line

Regulations:

- Ability to work in food environments.

- Data recording in file.

- Batch control.

- Statistic.

- LAN connectivity.

- Integration: SCADA, ERP.

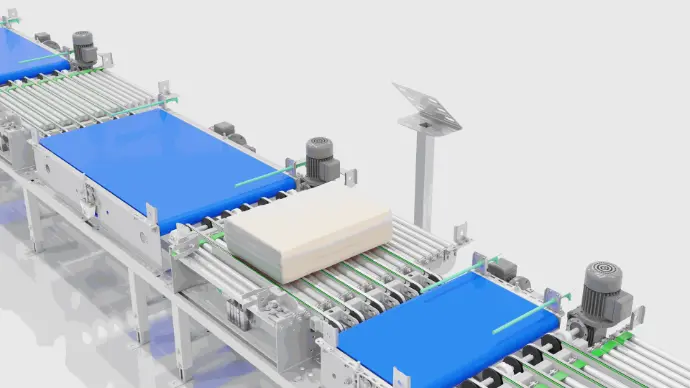

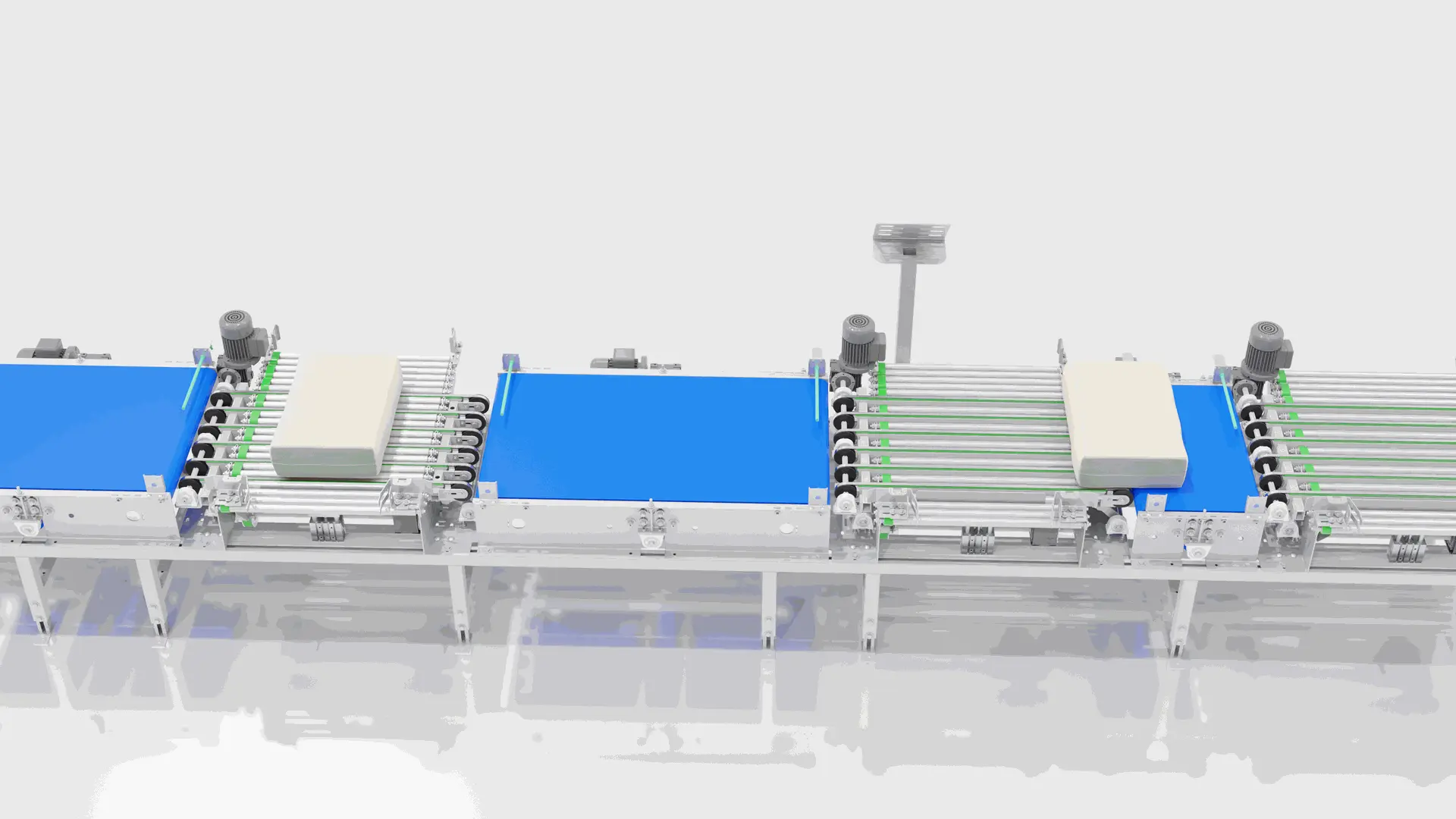

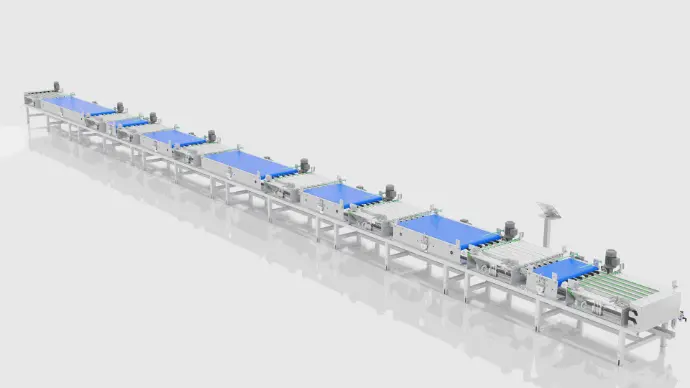

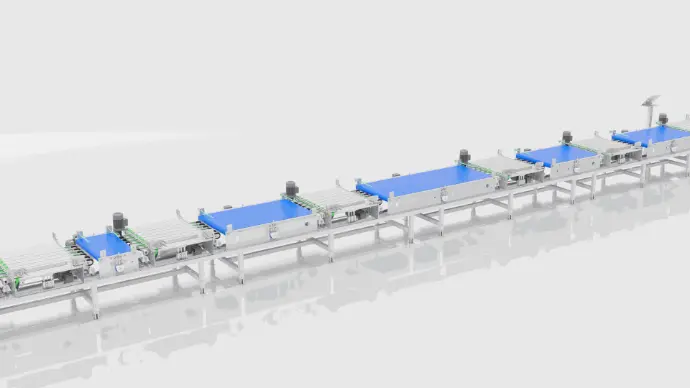

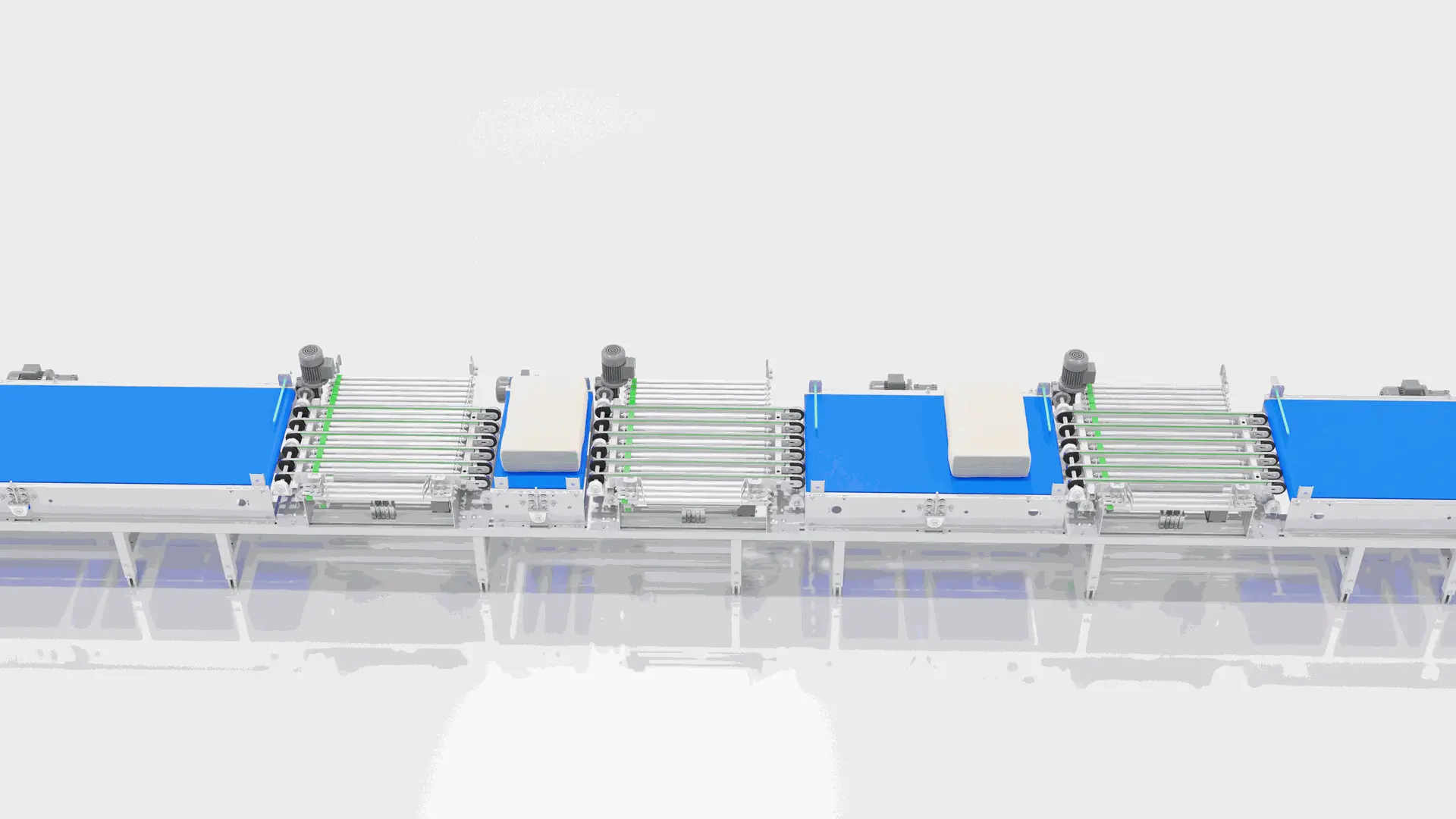

BAGSORTER

Bag collector

Customized transport system for receiving and distributing bags from several inlets to several outlets.

BAGSORTER

Bag collector

Customized transport system for receiving and distributing bags from several inlets to several outlets.

BAGSORTER

Bag collector

Customized transport system for receiving and distributing bags from several inlets to several outlets.

BAGSORTER

Bag collector

Customized transport system for receiving and distributing bags from several inlets to several outlets.

BAGSORTER

Bag collector

Customized transport system for receiving and distributing bags from several inlets to several outlets.

| Reference product | Bags or nets of different weights and sizes. |

| Cadences | Up to 60 units per minute. |

| Configuration | Modular and expandable system. |

| HMI |

Software for configuring entry and destination points, speeds, times, etc. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Handling:

- Máquina compacta y fácilmente integrable en línea.

Regulations:

- Ability to work in food environments.

-

Different levels of machine automation.

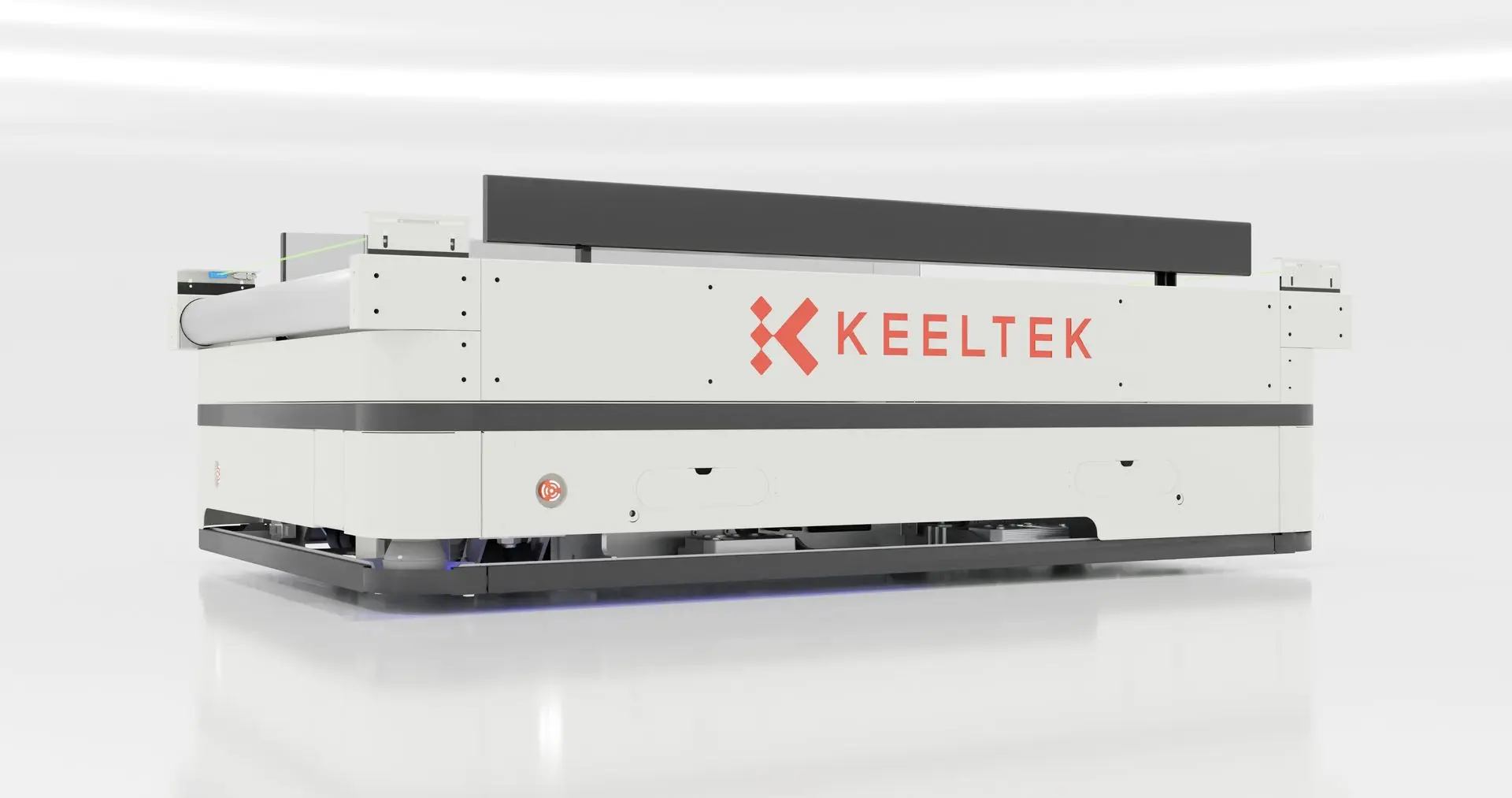

KMR FORKLIFT

Fork-type AMR robot

Autonomous mobile robot (AMR) for lifting and transporting loads from and/or to ground level.

KMR FORKLIFT

Fork-type AMR robot

Autonomous mobile robot (AMR) for lifting and transporting loads from and/or to ground level.

KMR FORKLIFT

Fork-type AMR robot

Autonomous mobile robot (AMR) for lifting and transporting loads from and/or to ground level.

KMR FORKLIFT

Fork-type AMR robot

Autonomous mobile robot (AMR) for lifting and transporting loads from and/or to ground level.

KMR FORKLIFT

Fork-type AMR robot

Autonomous mobile robot (AMR) for lifting and transporting loads from and/or to ground level.

KMR FORKLIFT

Fork-type AMR robot

Autonomous mobile robot (AMR) for lifting and transporting loads from and/or to ground level.

| Load |

Up to 1,400 kg |

| Referencee product |

Pallets or any similar platform |

| Positioning accuracy | Pallets or any similar platform |

|

Maximum speed |

1.5 m/s |

| Default navigation |

Laser |

Autonomy | Up to 6 hours |

Possible angle of inclination | Up to 5% |

Flexibility:

- Unlike AGVs with fixed routes, Keeltek's KMRs instantly adapt to changes in the plant layout.

Intuitive integration:

- Its user-friendly control software enables rapid programming, outperforming other AMRs that require specialized personnel, which streamlines implementation in packaging operations.

Enhanced security:

- Equipped with advanced sensors and obstacle detection systems, AKMRs ensure safe operations alongside human workers, outperforming AGVs in collaborative environments.

Cost efficiency:

- They offer a fast return on investment (ROI), estimated at 4-6 months, thanks to reduced labor costs and optimized flows, with more economical maintenance than AGVs because they do not depend on fixed infrastructure.

Effortless scalability:

- KMRs allow units to be added or tasks to be reconfigured easily, surpassing other AMRs and AGVs in flexibility to grow with production needs.

Accuracy in repetitive tasks:

- They optimize the transport of any product with high precision, reducing errors compared to manual solutions or less adaptable AGVs.

- 3D navigation camera.

- Self-loading.

- Fleet integration (expandable).

- Customized software and fleet management.

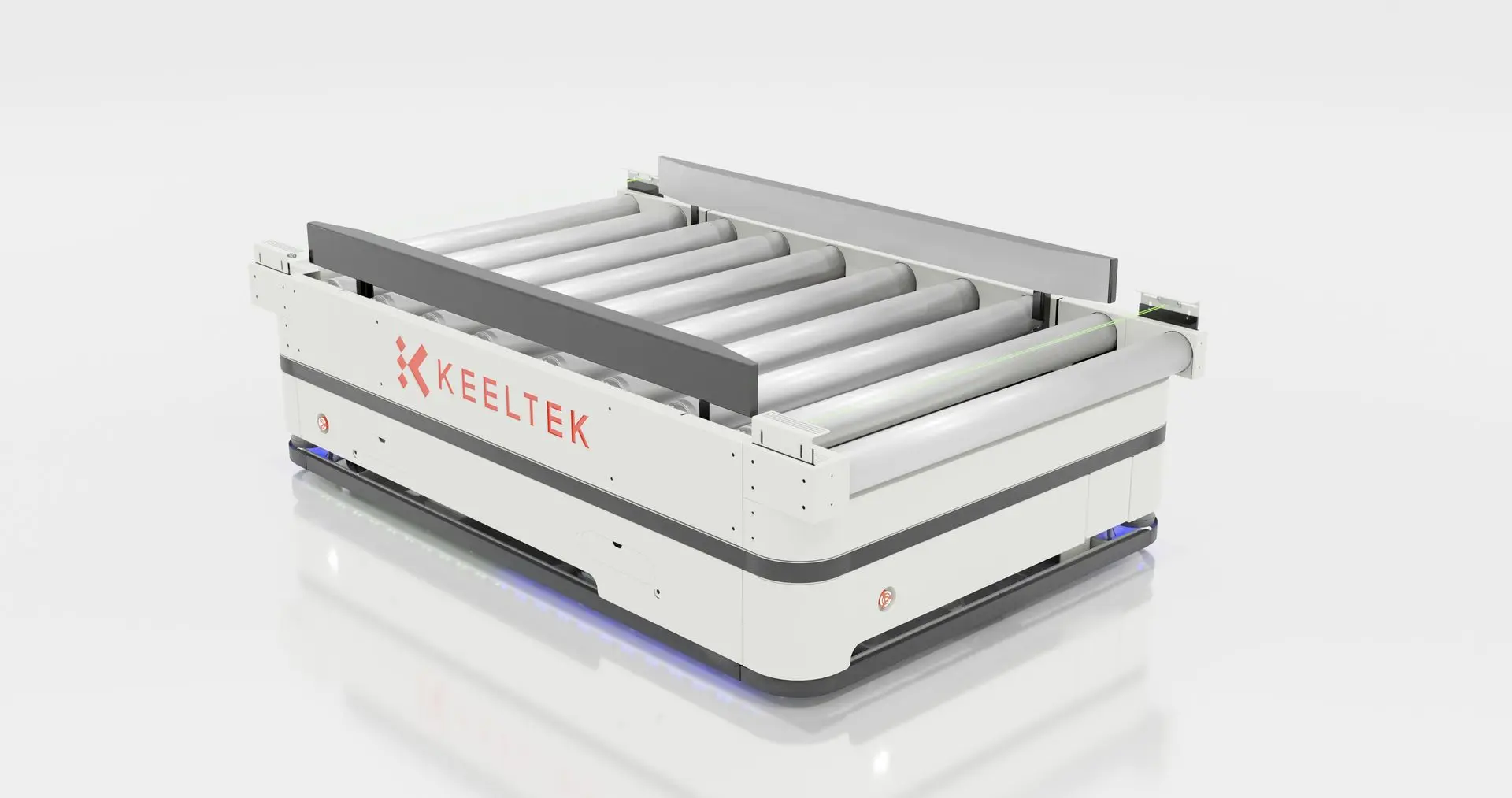

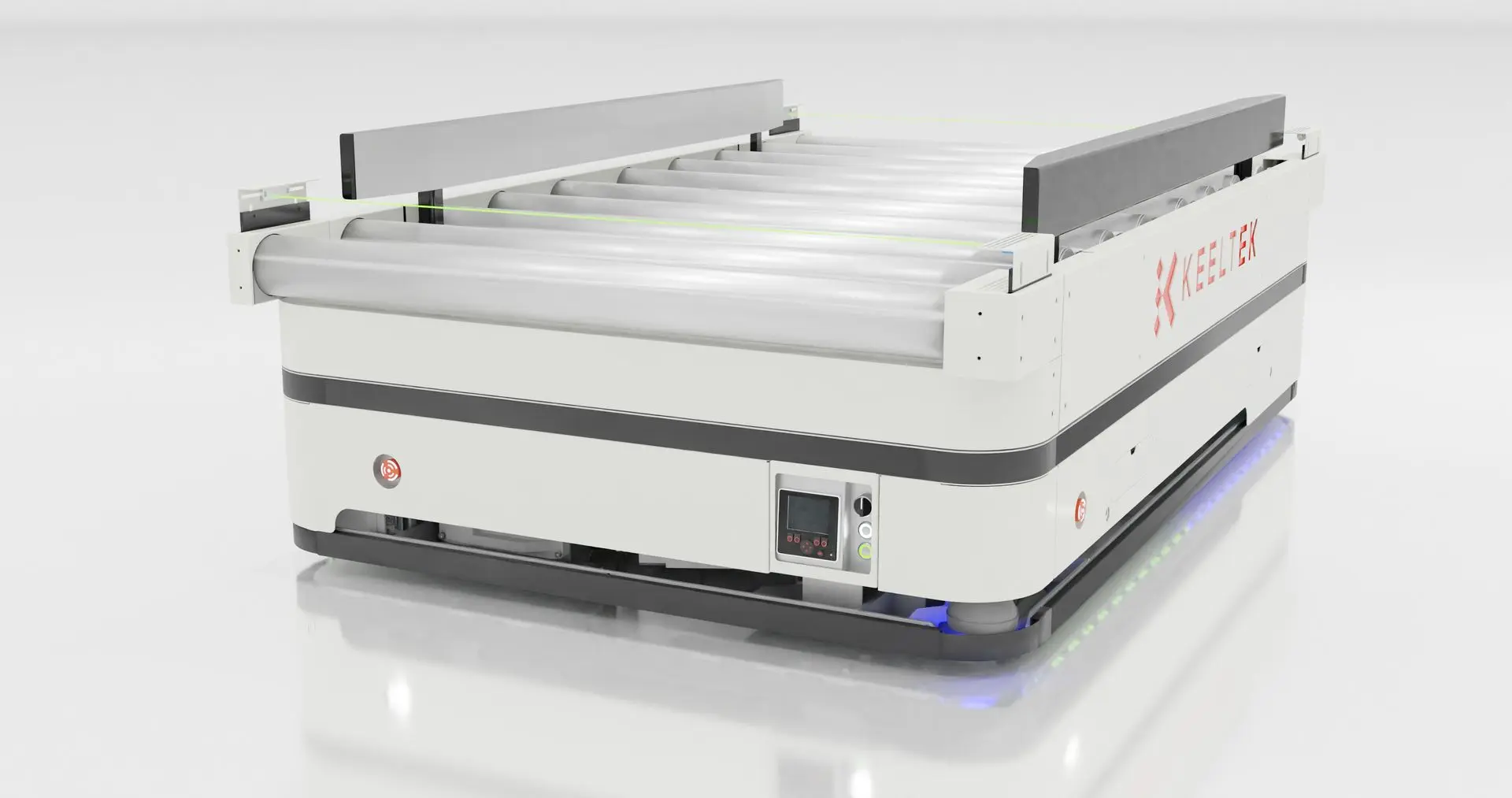

KMR MOUSE

Mouse-type AMR robot

Autonomous mobile robot (AMR) for level transport with different configurations.

KMR MOUSE

Mouse-type AMR robot

Autonomous mobile robot (AMR) for level transport with different configurations.

KMR MOUSE

Mouse-type AMR robot

Autonomous mobile robot (AMR) for level transport with different configurations.

KMR MOUSE

Mouse-type AMR robot

Autonomous mobile robot (AMR) for level transport with different configurations.

KMR MOUSE

Mouse-type AMR robot

Autonomous mobile robot (AMR) for level transport with different configurations.

| Load | Up to 1,500 kg |

| Referencee product |

Any. |

| Positioning accuracy | Pallets or any similar platform |

|

Maximum speed |

1.5 m/s |

| Default navigation |

Laser |

Autonomy | Up to 8 hours |

possible angle of inclination | Up to 5% |

Flexibility:

- A diferencia de los AGVs con rutas fijas, los KMR de Keeltek se adaptan instantáneamente a cambios en el layout de la planta.

Intuitive integration:

- Su software de control fácil de usar permite una programación rápida, superando a otros AMRs que requieren personal especializado, lo que agiliza la implementación en operaciones de empaque.

Seguridad mejorada:

- Equipped with advanced sensors and obstacle detection systems, AKMRs ensure safe operations alongside human workers, outperforming AGVs in collaborative environments.

Eficiencia de costos

- Ofrecen un retorno de inversión (ROI) rápido, estimado en 4-6 meses, gracias a la reducción de costos laborales y la optimización de flujos, con un mantenimiento más económico que los AGVs por no depender de infraestructura fija.

Escalabilidad sin esfuerzo

- Los KMR permiten añadir unidades o reconfigurar tareas fácilmente, superando a otros AMRs y AGVs en flexibilidad para crecer con las necesidades de producción.

Precisión en tareas repetitivas:

- They optimize the transport of any product with high precision, reducing errors compared to manual solutions or less adaptable AGVs.

- Different accessories for upper platform: rollers, lift, cobot, etc.

- 3D navigation camera.

- Self-loading.

- Fleet integration (expandable).

- Customized software and fleet management.

Request information instantly

Fill out the form below and provide detailed information about your preferred model.

All this without any obligation

Explore our solutions for the chemical industry in detail now.