Robotic solutions

Robotic solutions

Robotic solutions

NEW!

At KEELTEK, we offer customized advanced robotic integration solutions for your industrial processes. Our goal is to optimize efficiency, productivity, precision, and safety in your production lines. We offer a wide range of robotic solutions tailored to your specific industrial sector.

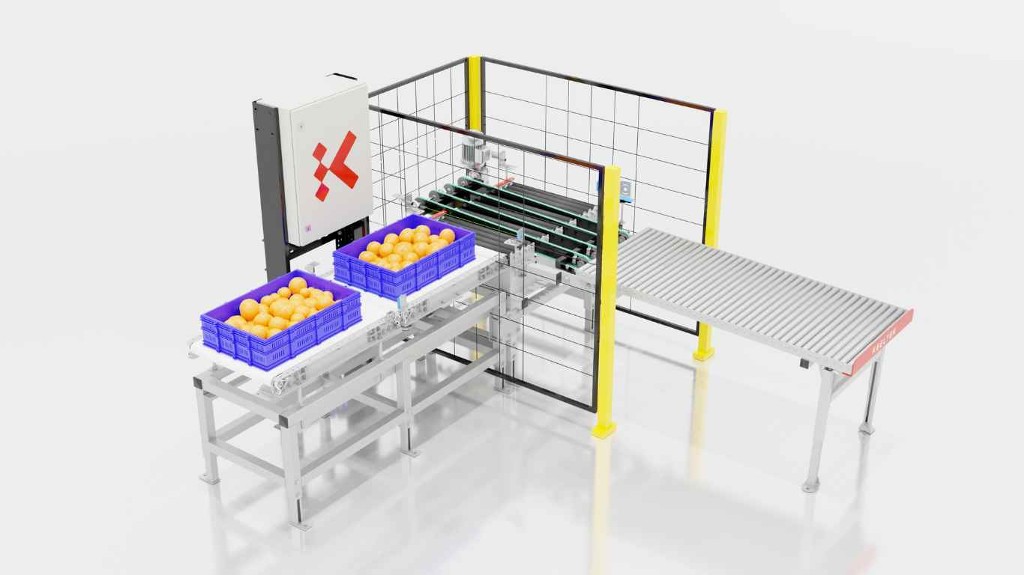

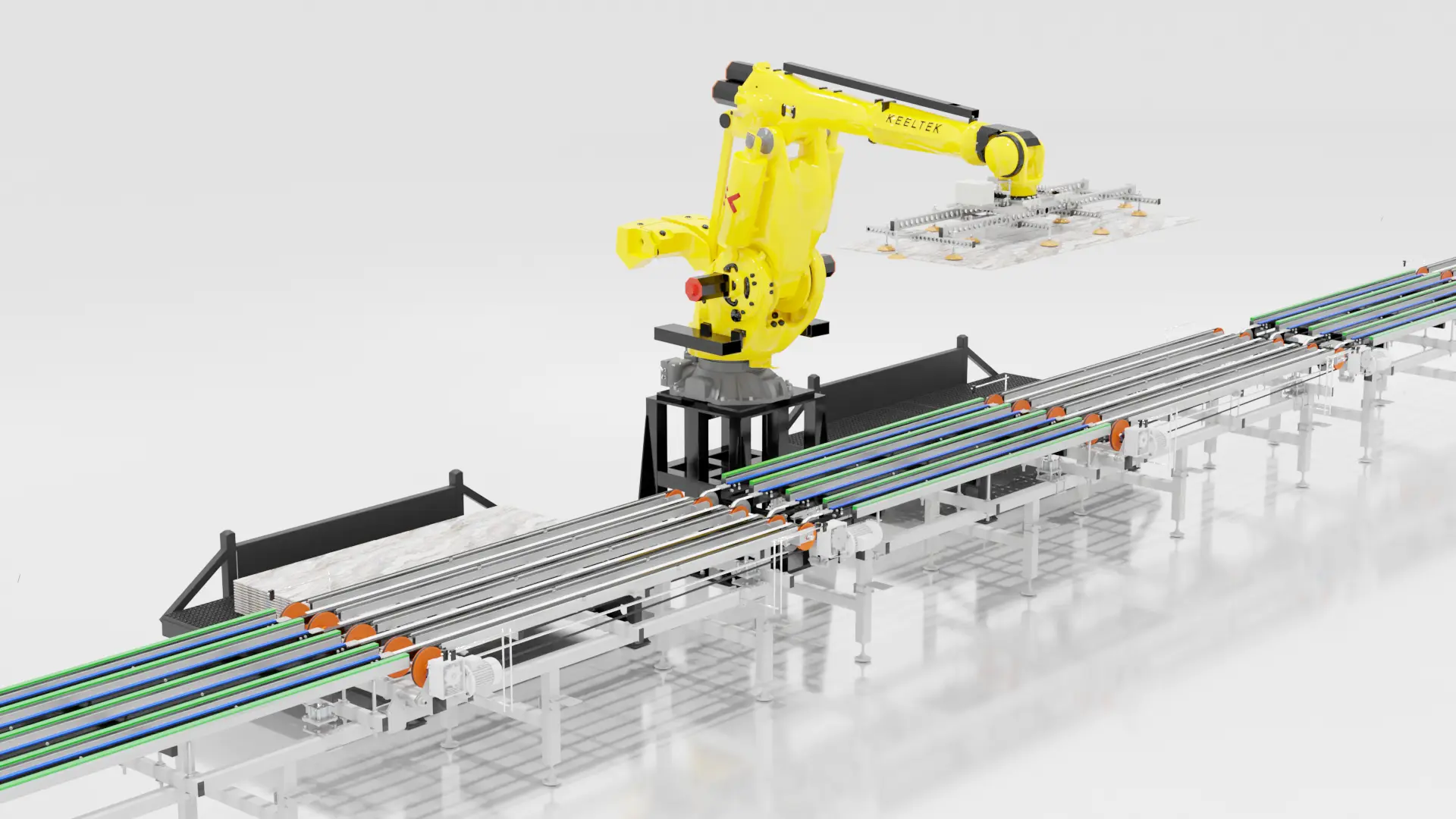

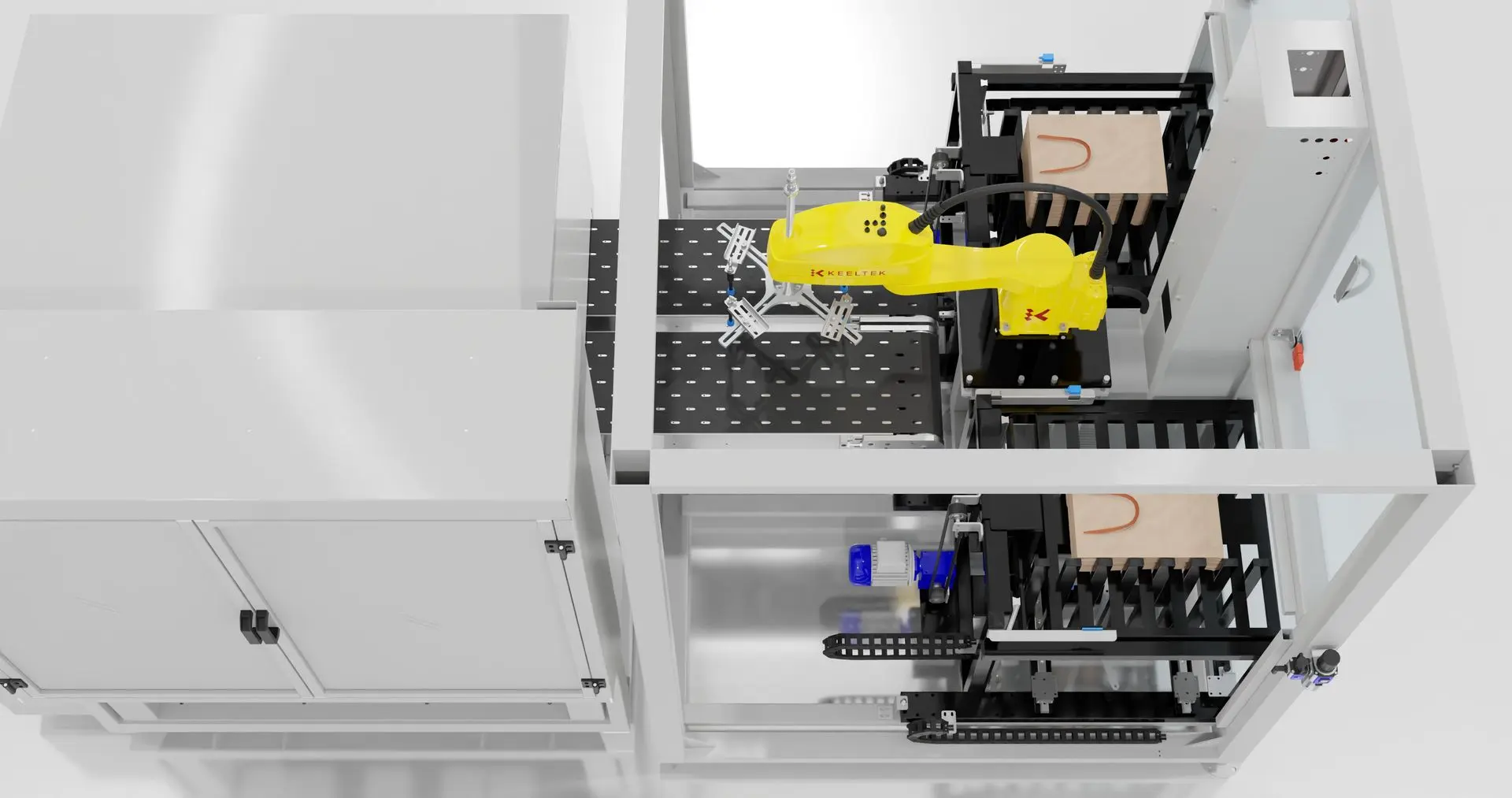

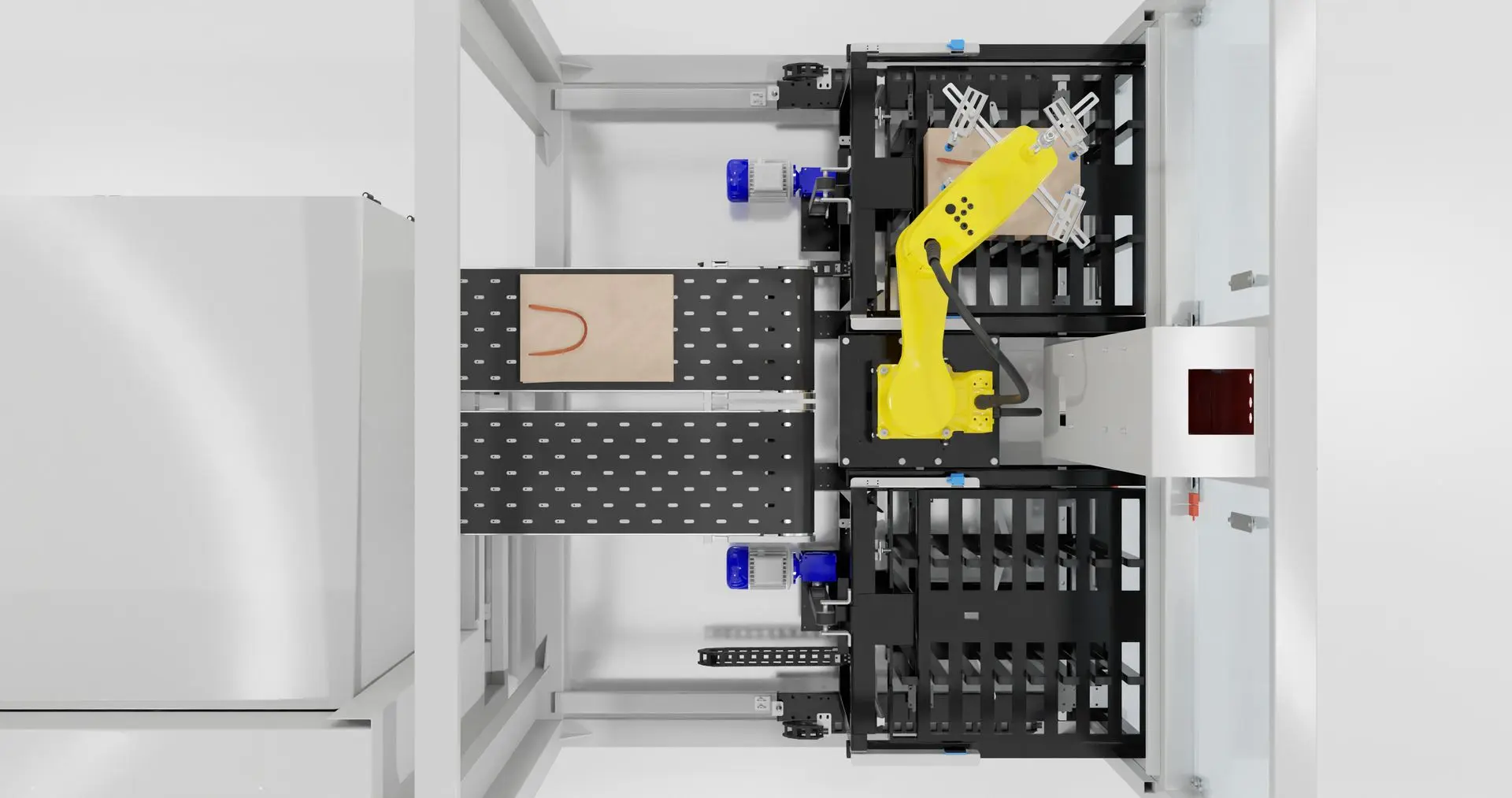

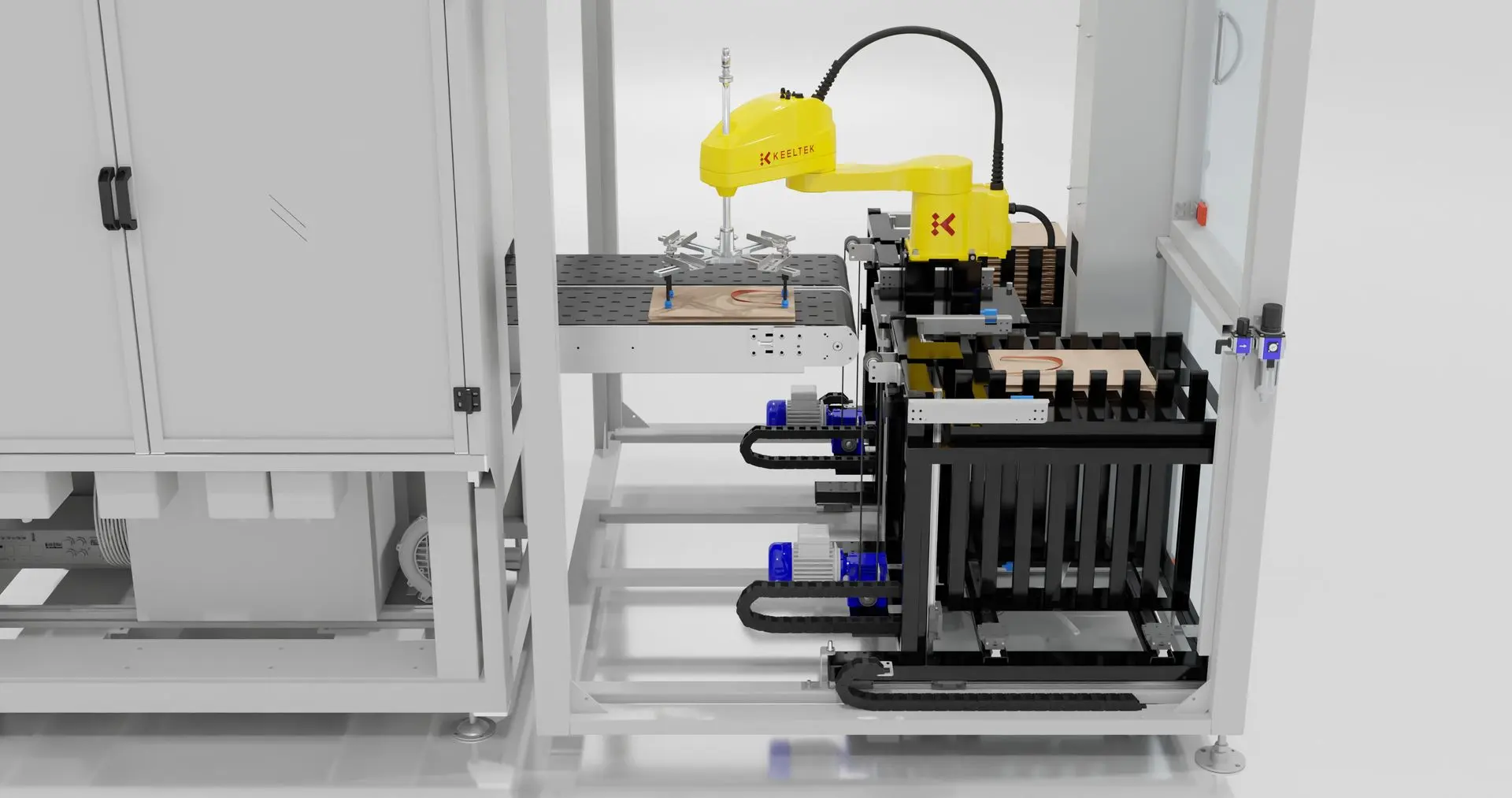

BRIOCELL

Robotic loading/unloading cell for assembly line

Loading and unloading of complex products using a robotic arm. Flexible solution tailored to the application.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

BRIOCELL

Robotic loading/unloading cell for assembly line

Loading and unloading of complex products using a robotic arm. Flexible solution tailored to the application.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

BRIOCELL

Robotic loading/unloading cell for assembly line

Loading and unloading of complex products using a robotic arm. Flexible solution tailored to the application.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

BRIOCELL

Robotic loading/unloading cell for assembly line

Loading and unloading of complex products using a robotic arm. Flexible solution tailored to the application.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

BRIOCELL

Robotic loading/unloading cell for assembly line

Loading and unloading of complex products using a robotic arm. Flexible solution tailored to the application.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

BRIOCELL

Robotic loading/unloading cell for assembly line

Loading and unloading of complex products using a robotic arm. Flexible solution tailored to the application.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

| Reference product | Varied |

| Maximum permissible load | Consult |

| Connectivity | LAN. |

| Cadences | Depending on the application. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

-

Depending on the application.

- KTS, remote assistance.

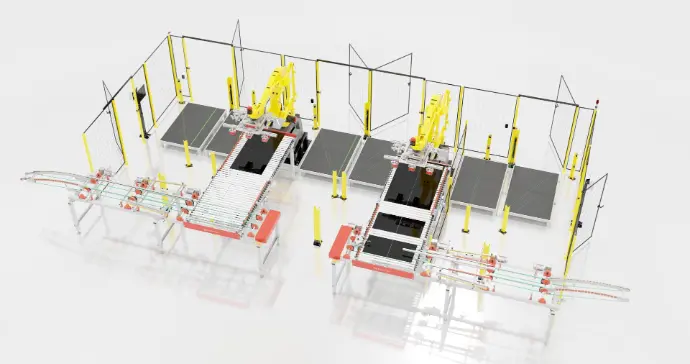

BRIOKOM

Robotic cell for managing lungs at the exit of a ceramic kiln

Robotic cell equipped with one or two robots for automated management in the oven exit area, acting as a buffer (to platforms, bread trays, pallets, or AGV/forklift systems) in the event of occasional and emergency stoppages before the sorting units, in-line rectification, and smart warehouses.

Automated management of model changes online with the smart buffer function.

Perfect for the following sectors:

Ceramic Industry

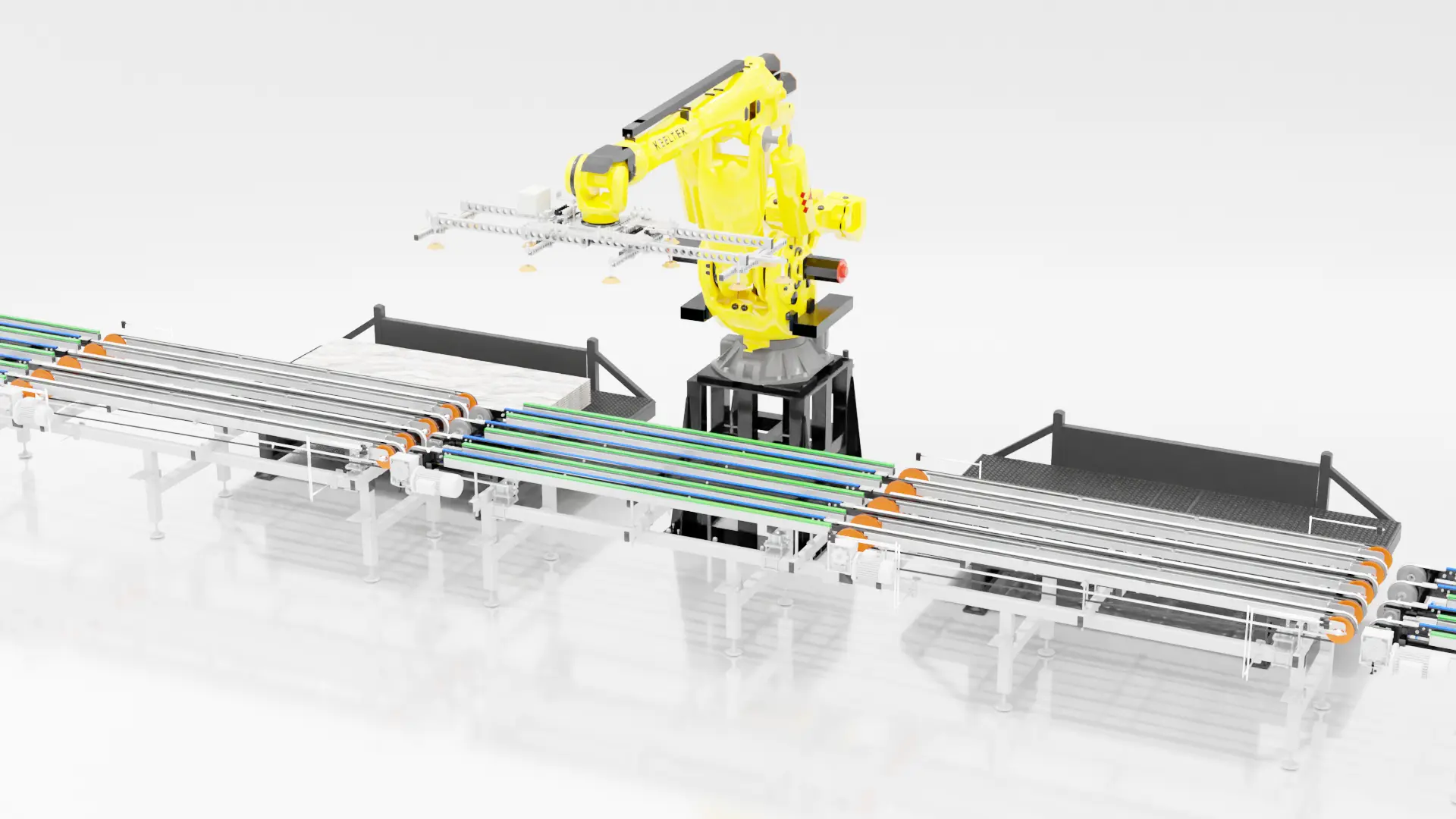

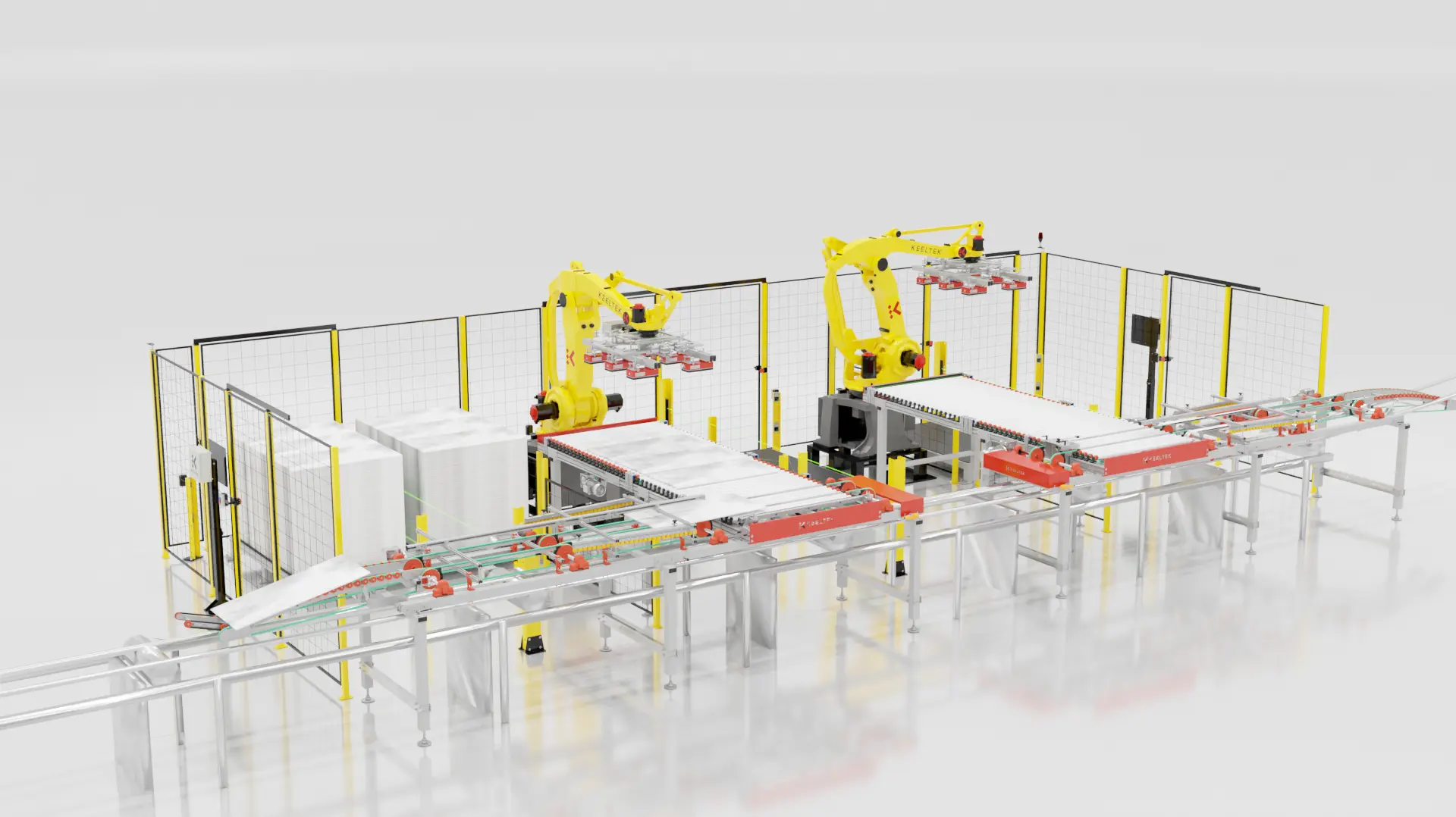

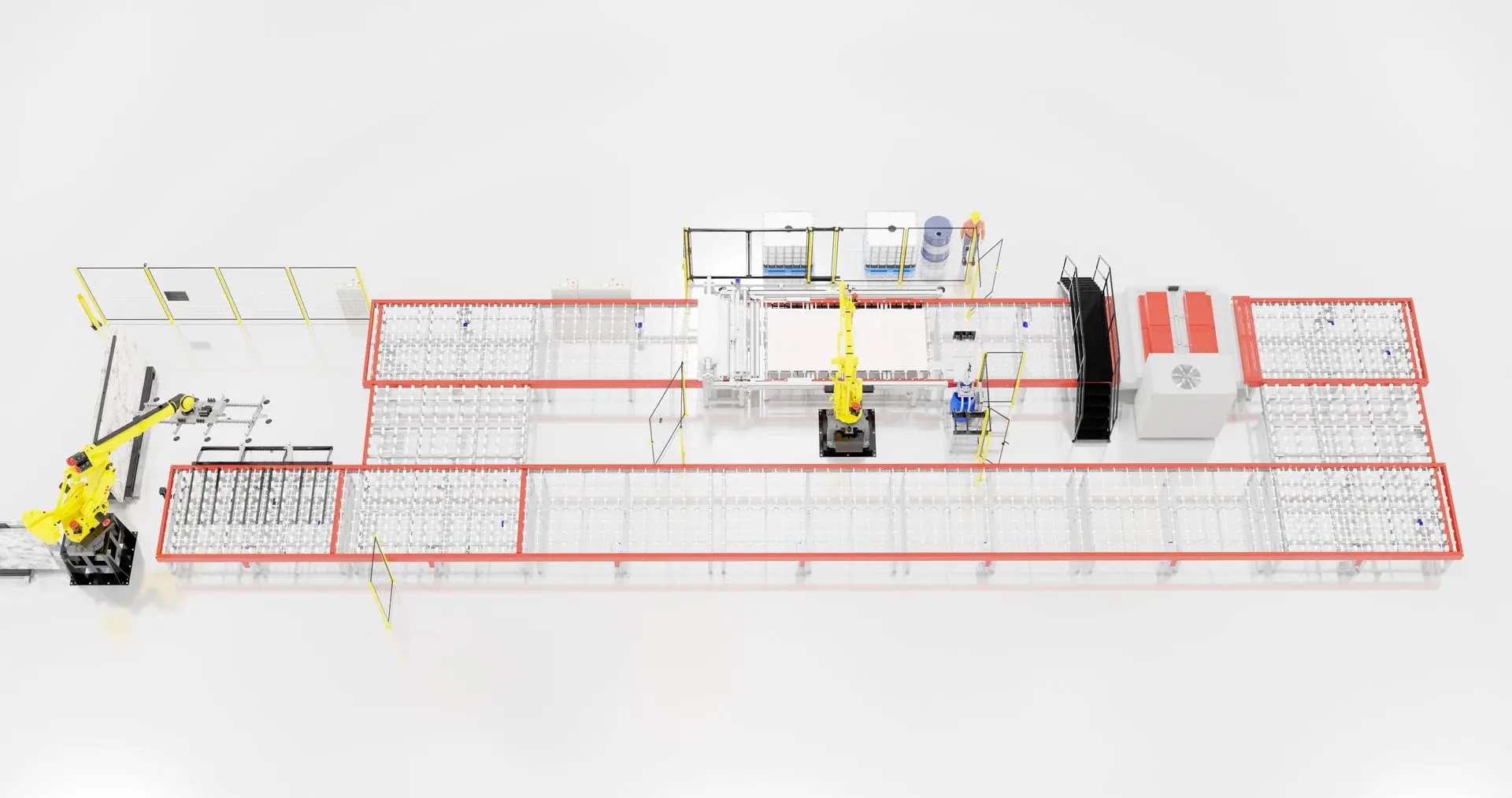

BRIOKOM

Robotic cell for managing lungs at the exit of a ceramic kiln

Robotic cell equipped with one or two robots for automated management in the oven exit area, acting as a buffer (to platforms, bread trays, pallets, or AGV/forklift systems) in the event of occasional and emergency stoppages before the sorting units, in-line rectification, and smart warehouses.

Automated management of model changes online with the smart buffer function.

Perfect for the following sectors:

Ceramic Industry

BRIOKOM

Robotic cell for managing lungs at the exit of a ceramic kiln

Robotic cell equipped with one or two robots for automated management in the oven exit area, acting as a buffer (to platforms, bread trays, pallets, or AGV/forklift systems) in the event of occasional and emergency stoppages before the sorting units, in-line rectification, and smart warehouses.

Automated management of model changes online with the smart buffer function.

Perfect for the following sectors:

Ceramic Industry

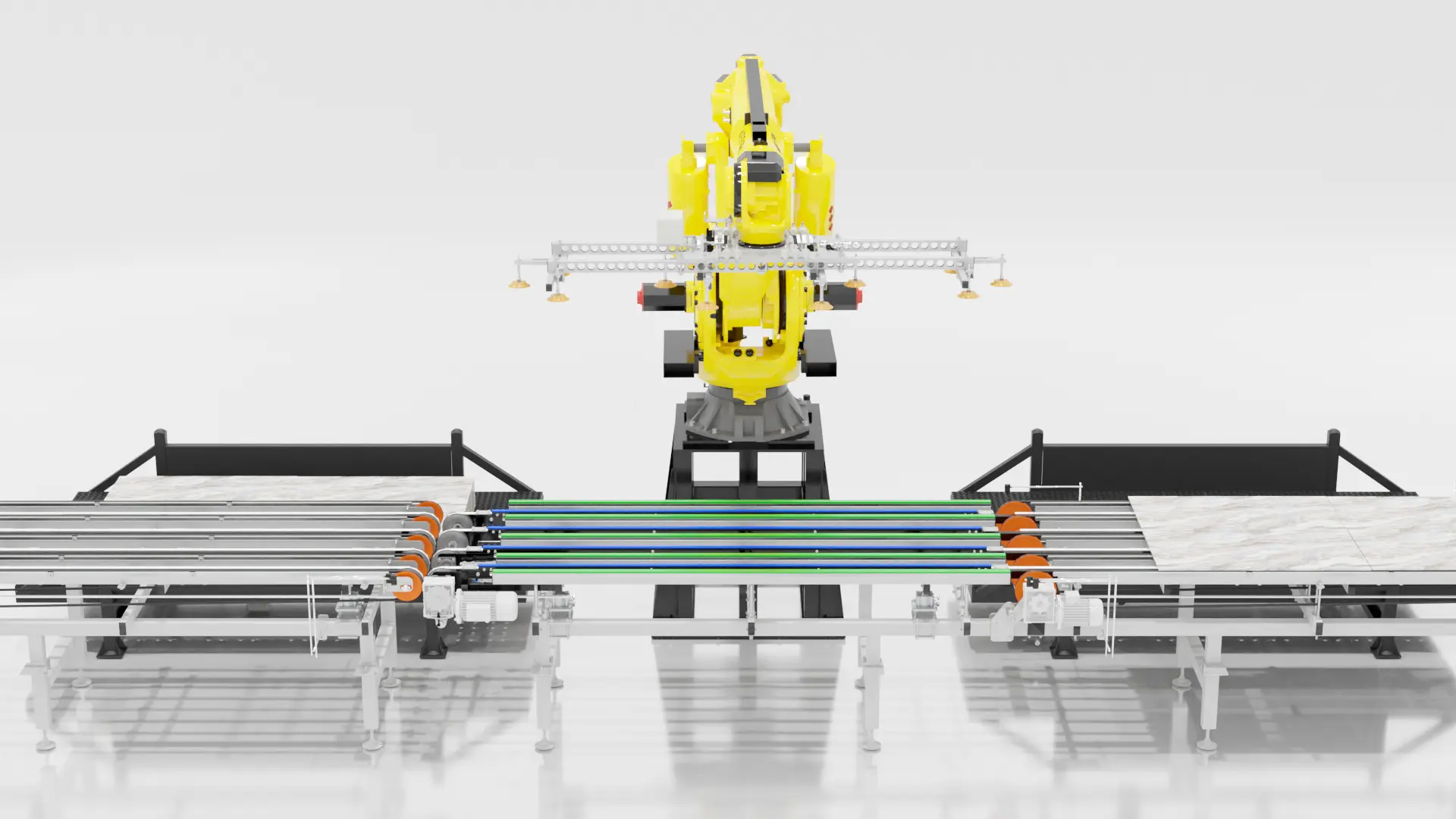

BRIOKOM

Robotic cell for managing lungs at the exit of a ceramic kiln

Robotic cell equipped with one or two robots for automated management in the oven exit area, acting as a buffer (to platforms, bread trays, pallets, or AGV/forklift systems) in the event of occasional and emergency stoppages before the sorting units, in-line rectification, and smart warehouses.

Automated management of model changes online with the smart buffer function.

Perfect for the following sectors:

Ceramic Industry

BRIOKOM

Robotic cell for managing lungs at the exit of a ceramic kiln

Robotic cell equipped with one or two robots for automated management in the oven exit area, acting as a buffer (to platforms, bread trays, pallets, or AGV/forklift systems) in the event of occasional and emergency stoppages before the sorting units, in-line rectification, and smart warehouses.

Automated management of model changes online with the smart buffer function.

Perfect for the following sectors:

Ceramic Industry

BRIOKOM

Robotic cell for managing lungs at the exit of a ceramic kiln

Robotic cell equipped with one or two robots for automated management in the oven exit area, acting as a buffer (to platforms, bread trays, pallets, or AGV/forklift systems) in the event of occasional and emergency stoppages before the sorting units, in-line rectification, and smart warehouses.

Automated management of model changes online with the smart buffer function.

Perfect for the following sectors:

Ceramic Industry

BRIOKOM

Robotic cell for managing lungs at the exit of a ceramic kiln

Robotic cell equipped with one or two robots for automated management in the oven exit area, acting as a buffer (to platforms, bread trays, pallets, or AGV/forklift systems) in the event of occasional and emergency stoppages before the sorting units, in-line rectification, and smart warehouses.

Automated management of model changes online with the smart buffer function.

Perfect for the following sectors:

Ceramic Industry

BRIOKOM

Robotic cell for managing lungs at the exit of a ceramic kiln

Robotic cell equipped with one or two robots for automated management in the oven exit area, acting as a buffer (to platforms, bread trays, pallets, or AGV/forklift systems) in the event of occasional and emergency stoppages before the sorting units, in-line rectification, and smart warehouses.

Automated management of model changes online with the smart buffer function.

Perfect for the following sectors:

Ceramic Industry

BRIOKOM

Robotic cell for managing lungs at the exit of a ceramic kiln

Robotic cell equipped with one or two robots for automated management in the oven exit area, acting as a buffer (to platforms, bread trays, pallets, or AGV/forklift systems) in the event of occasional and emergency stoppages before the sorting units, in-line rectification, and smart warehouses.

Automated management of model changes online with the smart buffer function.

Perfect for the following sectors:

Ceramic Industry

| Reference product | Any ceramic format. Compatible with selection, in-line grinding, and smart warehouses. |

| Mosaicos | Any tile configuration |

| Connectivity | LAN. |

| Cadences | Designed to handle high production levels from the kiln exit. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

- Pallets and fixed or interchangeable platforms using forklifts (operator management) or AGVs (automated management).

- KTS, remote assistance.

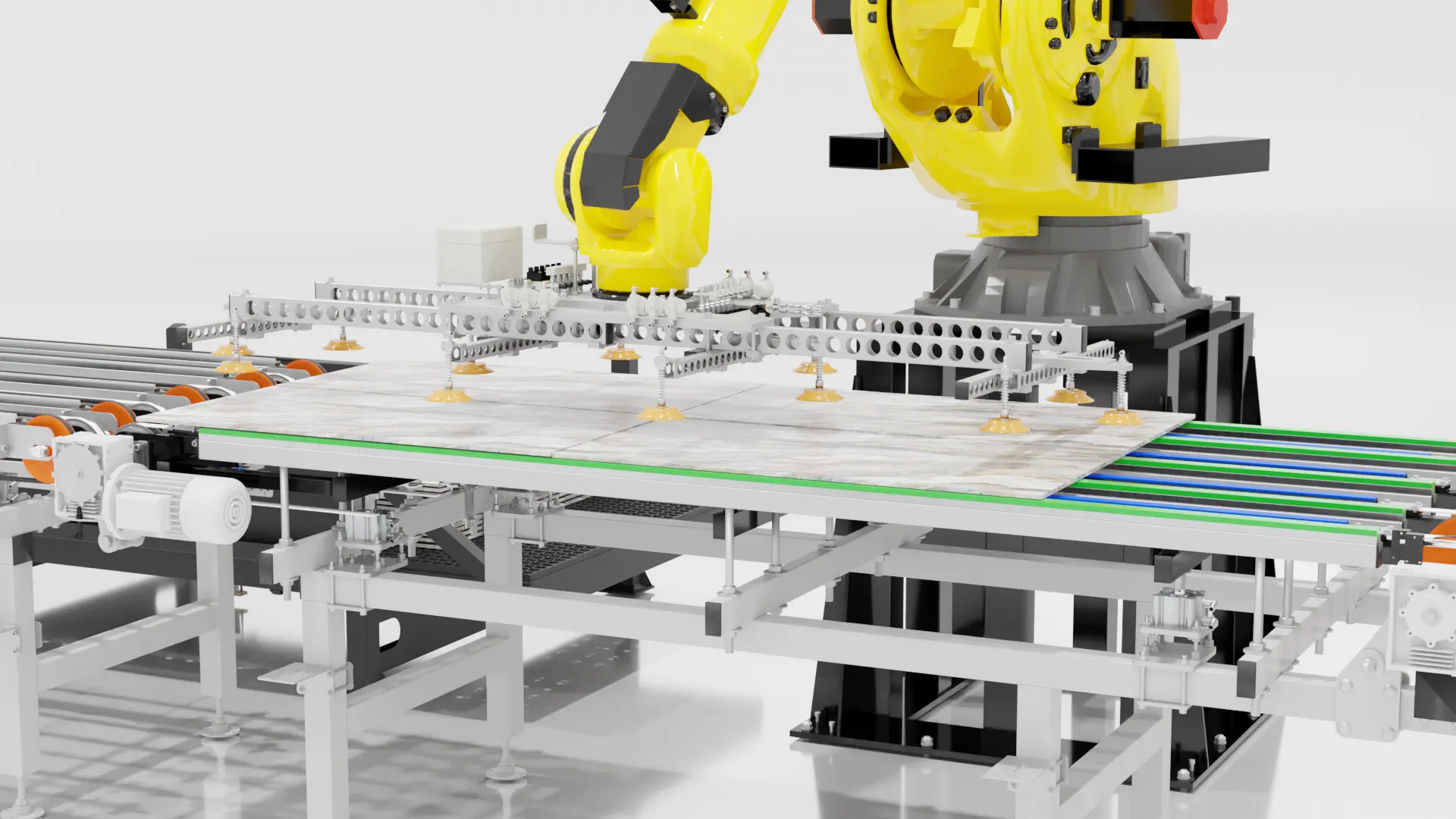

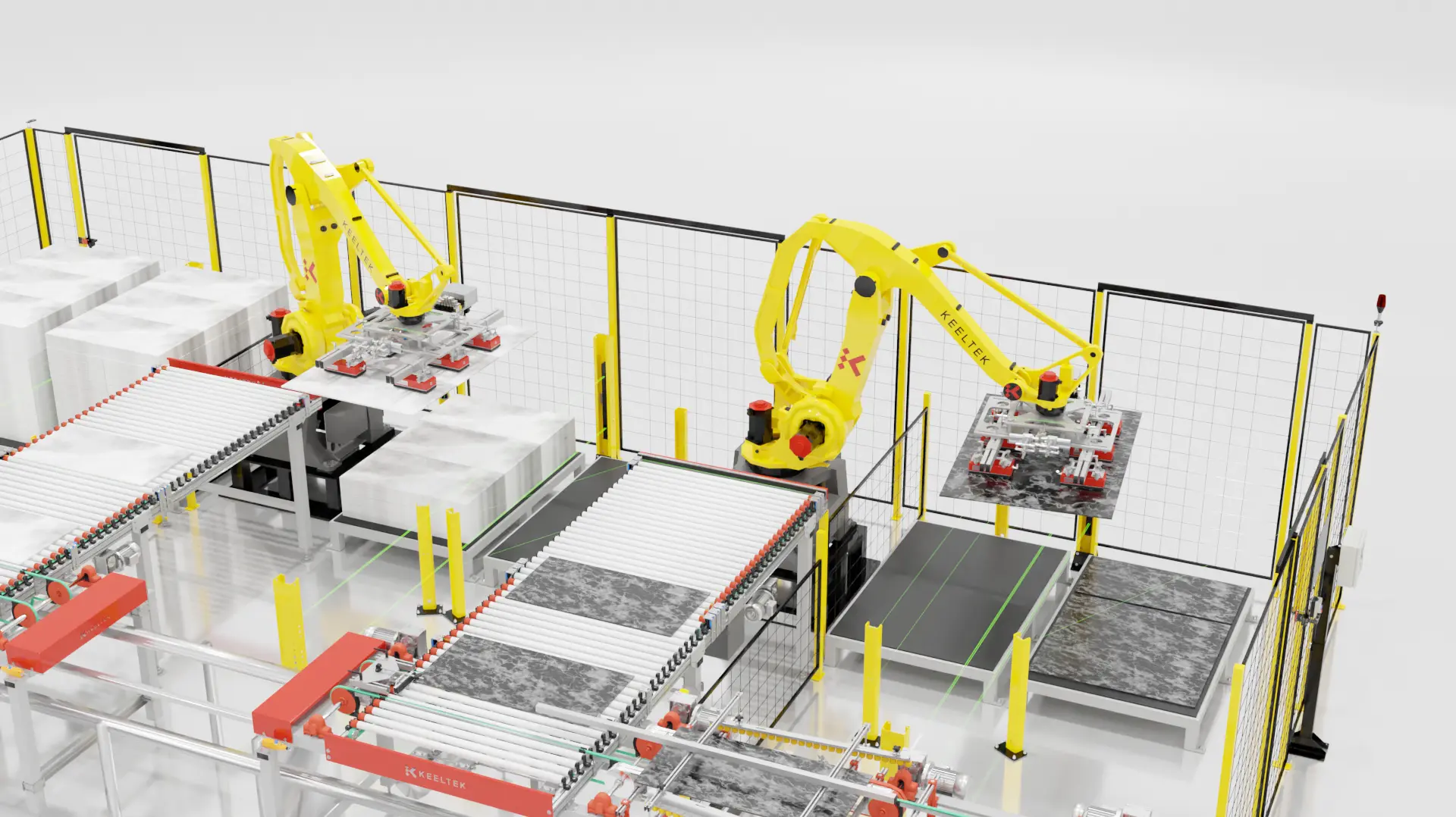

BRIOKOR

Ceramic reinforcement line

Fully automated line for the automated reinforcement of large XXL ceramic formats and thin ceramic sheets. Reinforcement is carried out using fiberglass, carbon fiber, or similar mesh or fabric and two-component polyurethane adhesives.

Perfect for the following sectors:

Ceramic

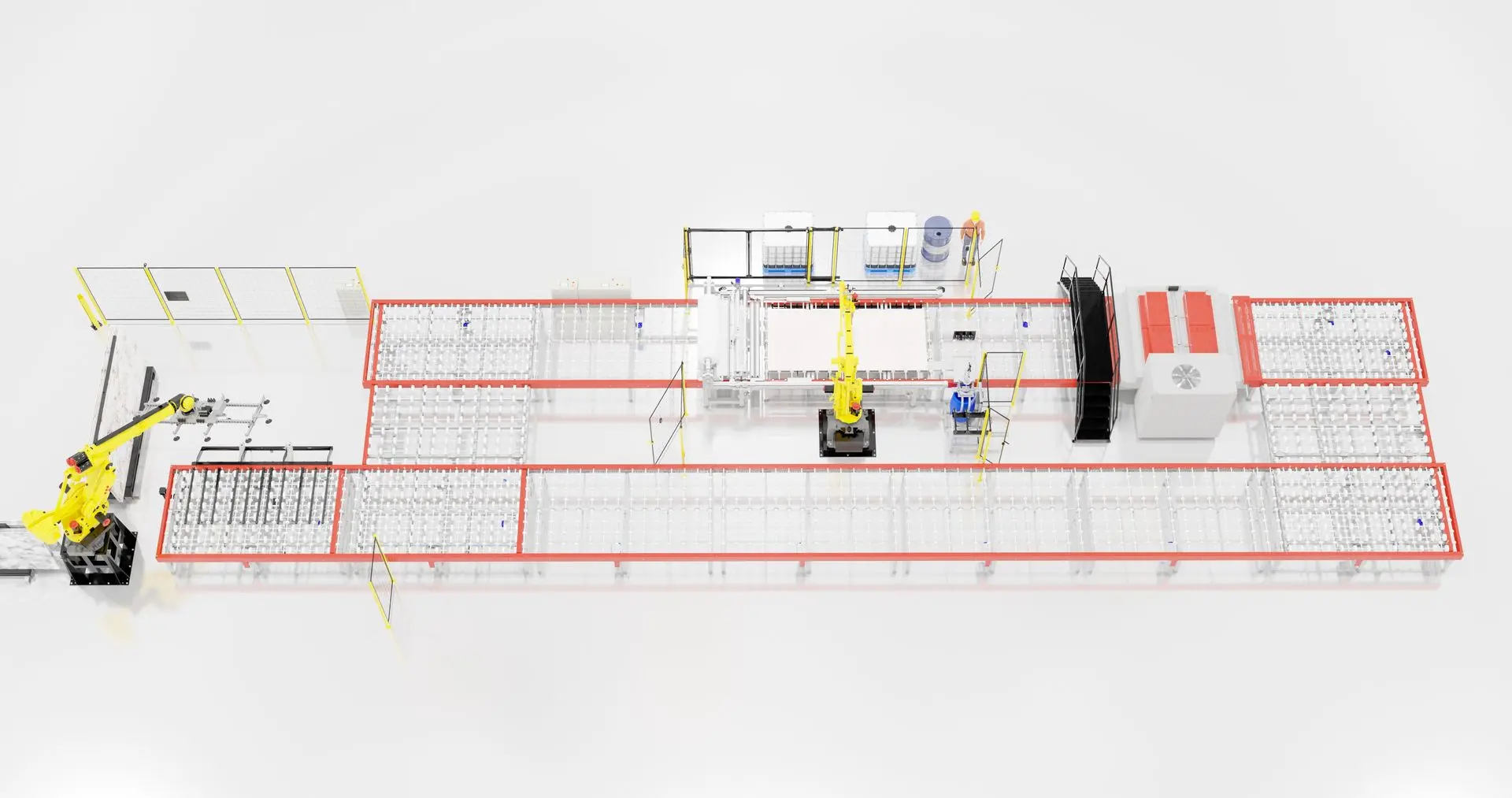

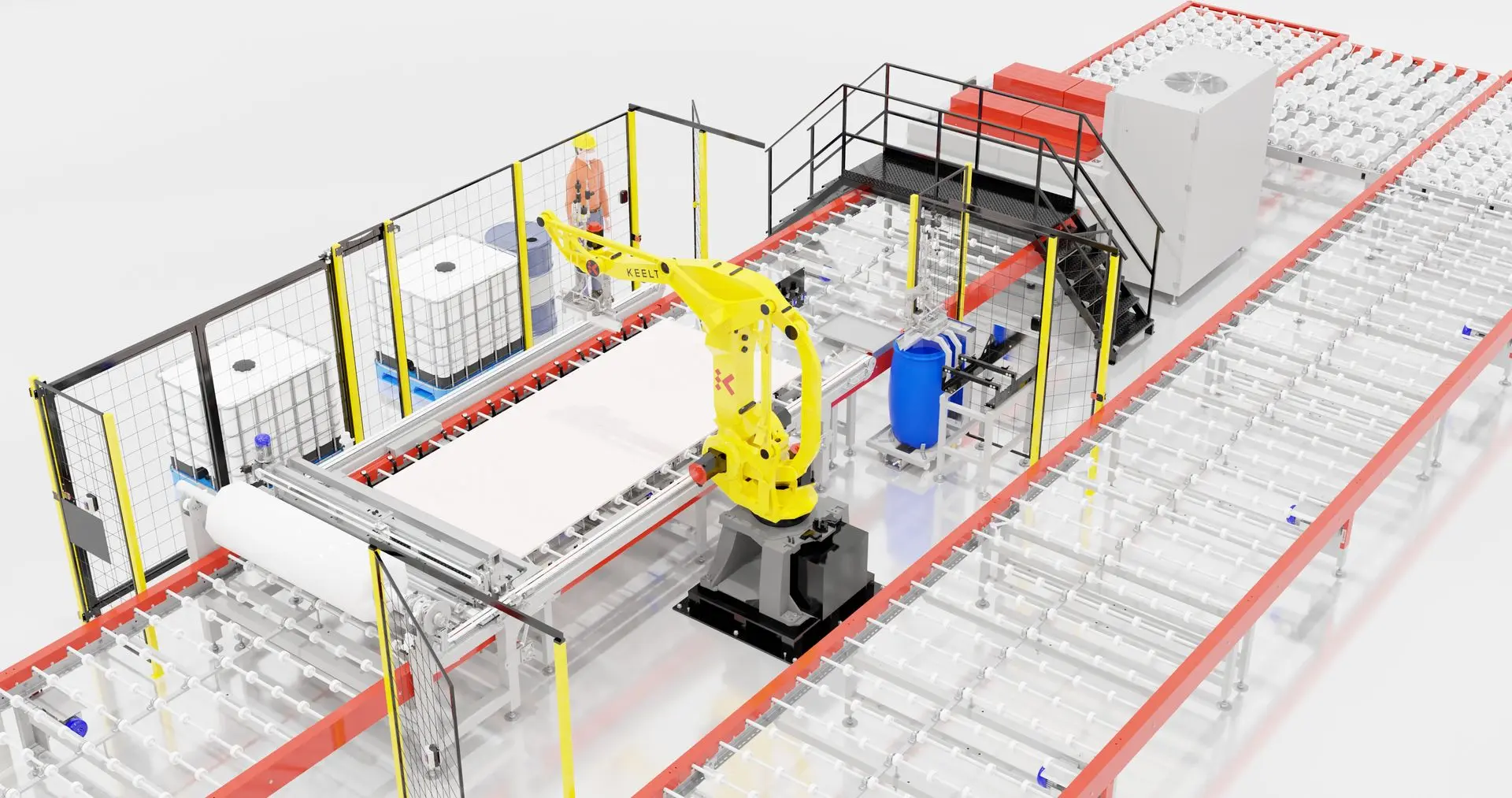

BRIOKOR

Ceramic reinforcement line

Fully automated line for the automated reinforcement of large XXL ceramic formats and thin ceramic sheets. Reinforcement is carried out using fiberglass, carbon fiber, or similar mesh or fabric and two-component polyurethane adhesives.

Perfect for the following sectors:

Ceramic

BRIOKOR

Ceramic reinforcement line

Fully automated line for the automated reinforcement of large XXL ceramic formats and thin ceramic sheets. Reinforcement is carried out using fiberglass, carbon fiber, or similar mesh or fabric and two-component polyurethane adhesives.

Perfect for the following sectors:

Ceramic

BRIOKOR

Ceramic reinforcement line

Fully automated line for the automated reinforcement of large XXL ceramic formats and thin ceramic sheets. Reinforcement is carried out using fiberglass, carbon fiber, or similar mesh or fabric and two-component polyurethane adhesives.

Perfect for the following sectors:

Ceramic

BRIOKOR

Ceramic reinforcement line

Fully automated line for the automated reinforcement of large XXL ceramic formats and thin ceramic sheets. Reinforcement is carried out using fiberglass, carbon fiber, or similar mesh or fabric and two-component polyurethane adhesives.

Perfect for the following sectors:

Ceramic

BRIOKOR

Ceramic reinforcement line

Fully automated line for the automated reinforcement of large XXL ceramic formats and thin ceramic sheets. Reinforcement is carried out using fiberglass, carbon fiber, or similar mesh or fabric and two-component polyurethane adhesives.

Perfect for the following sectors:

Ceramic

| Reference product | Virtually any ceramic format or XXL ceramic tile. PATENTED fiberglass fabric application technology. |

| Maximum permissible load | Consult |

| Connectivity | LAN. |

| Cadences | Up to 60 pieces/hour |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Features:

- Simple and intuitive creation of mosaics by the operator using proprietary software.

- Reversed layer function for improved stability.

Safety and ergonomics:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

- Designed with 100% clean electric technology, avoiding the emission of particles into the atmosphere (airbrushing) and CO2 emissions (curing by gas combustion).

Durability

- Machine manufactured from steel processed by laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Descarga a pancones o caballetes, intercambiables mediante toritos (gestión operario) o AGVs. (gestión automatizada).

- Posibilidad de añadir celdas robóticas de carga y/o descarga.

- Configuración lineal o con retorno en U.

- KTS, remote assistance.

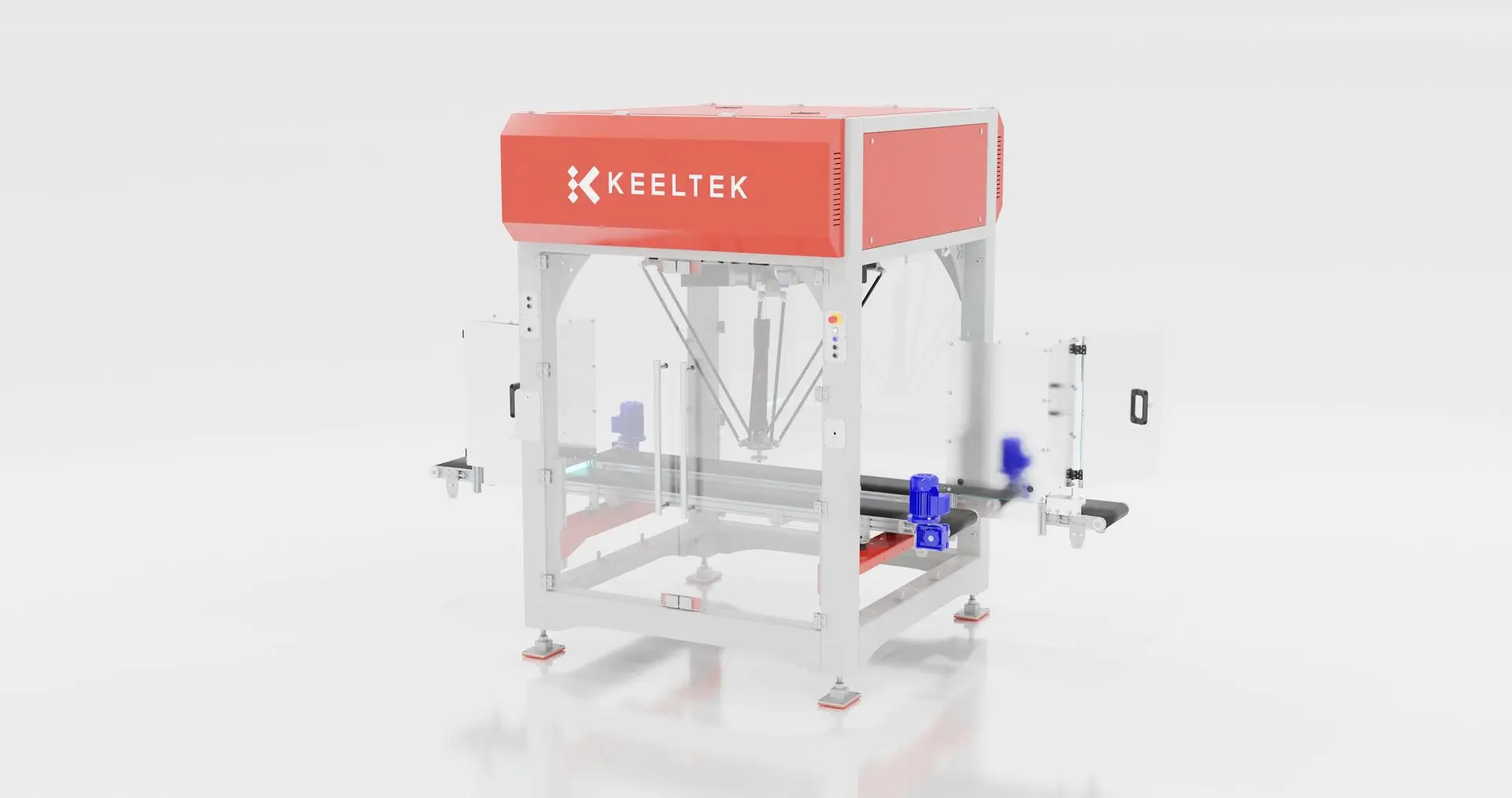

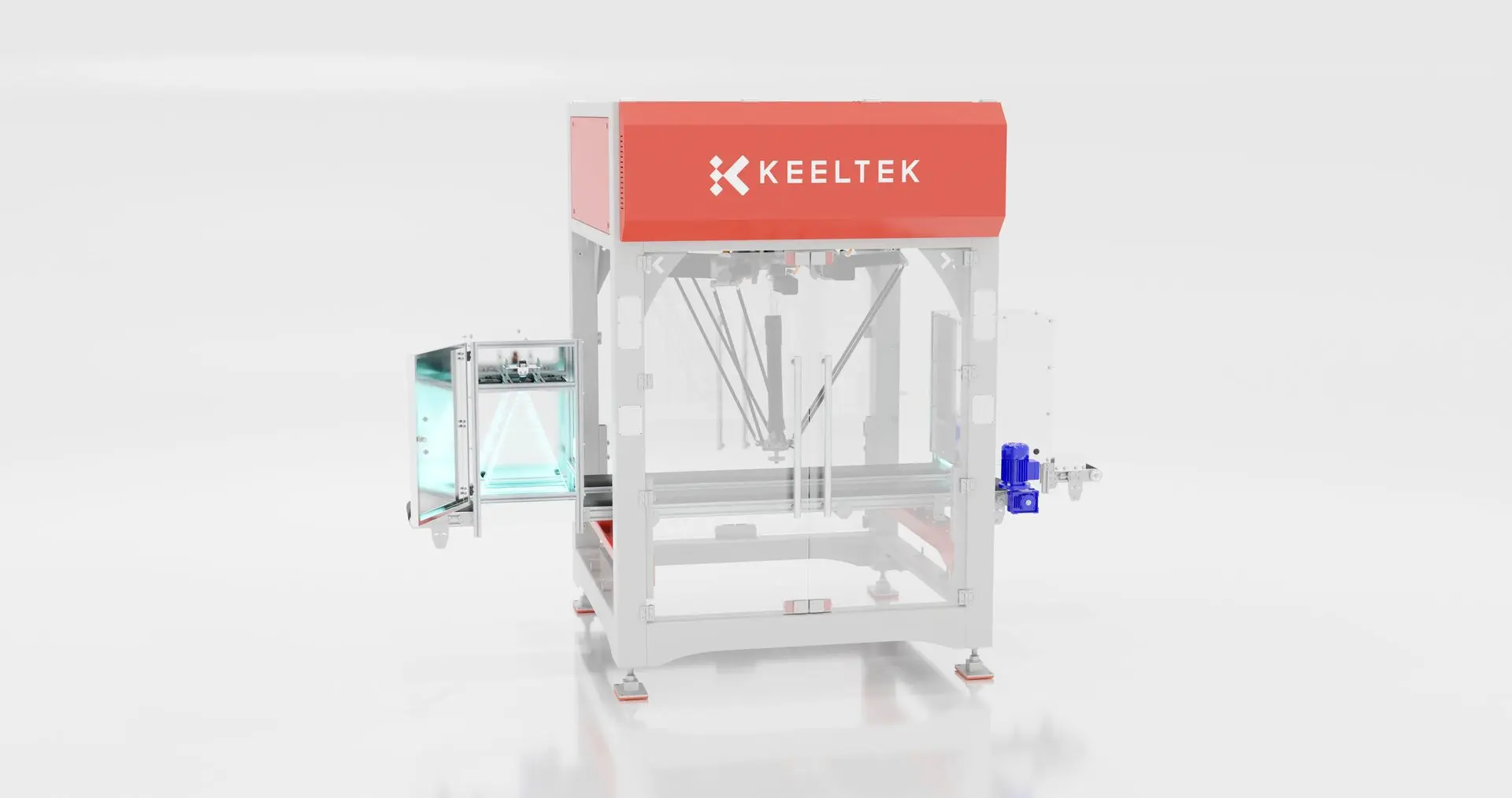

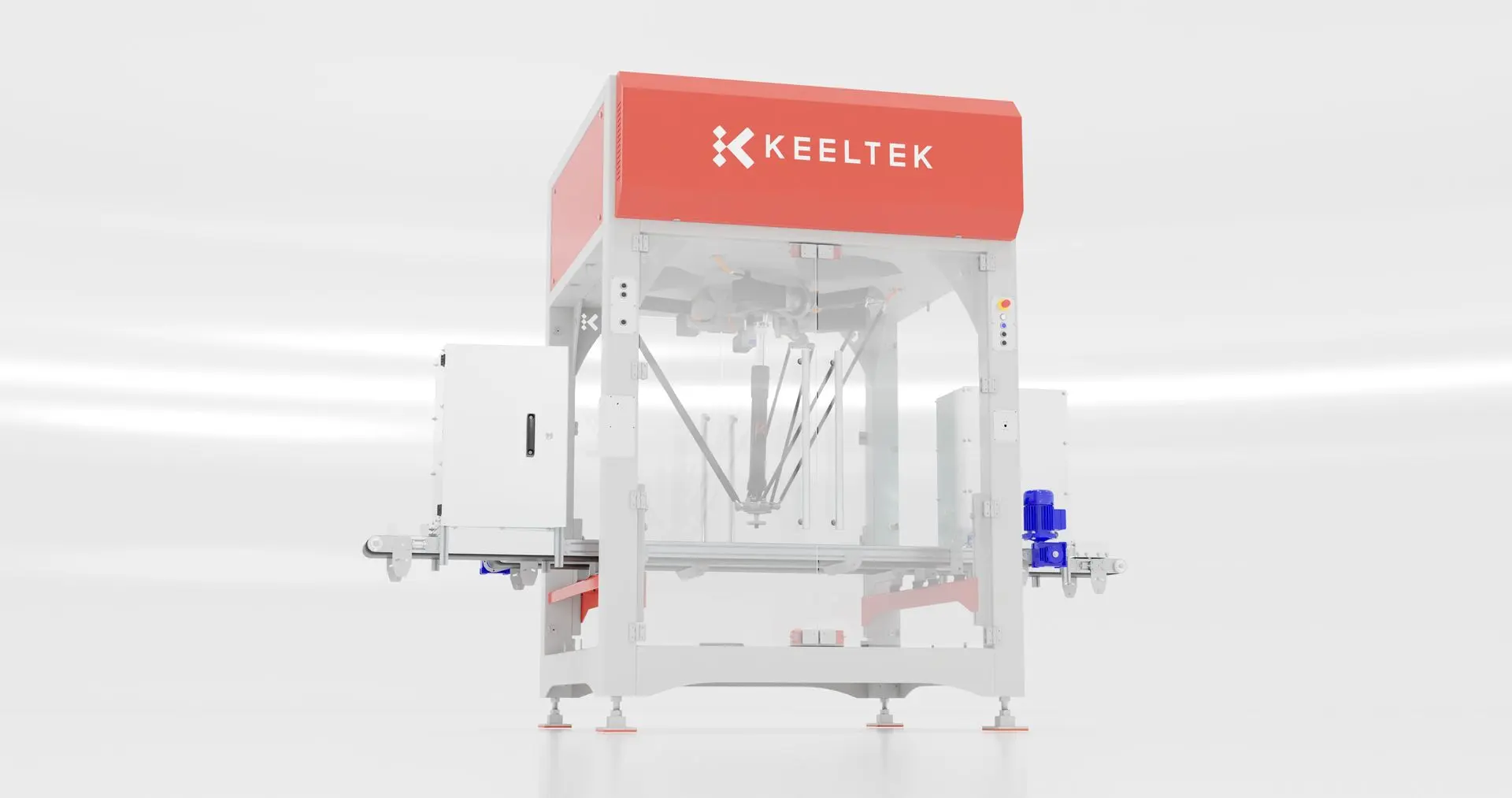

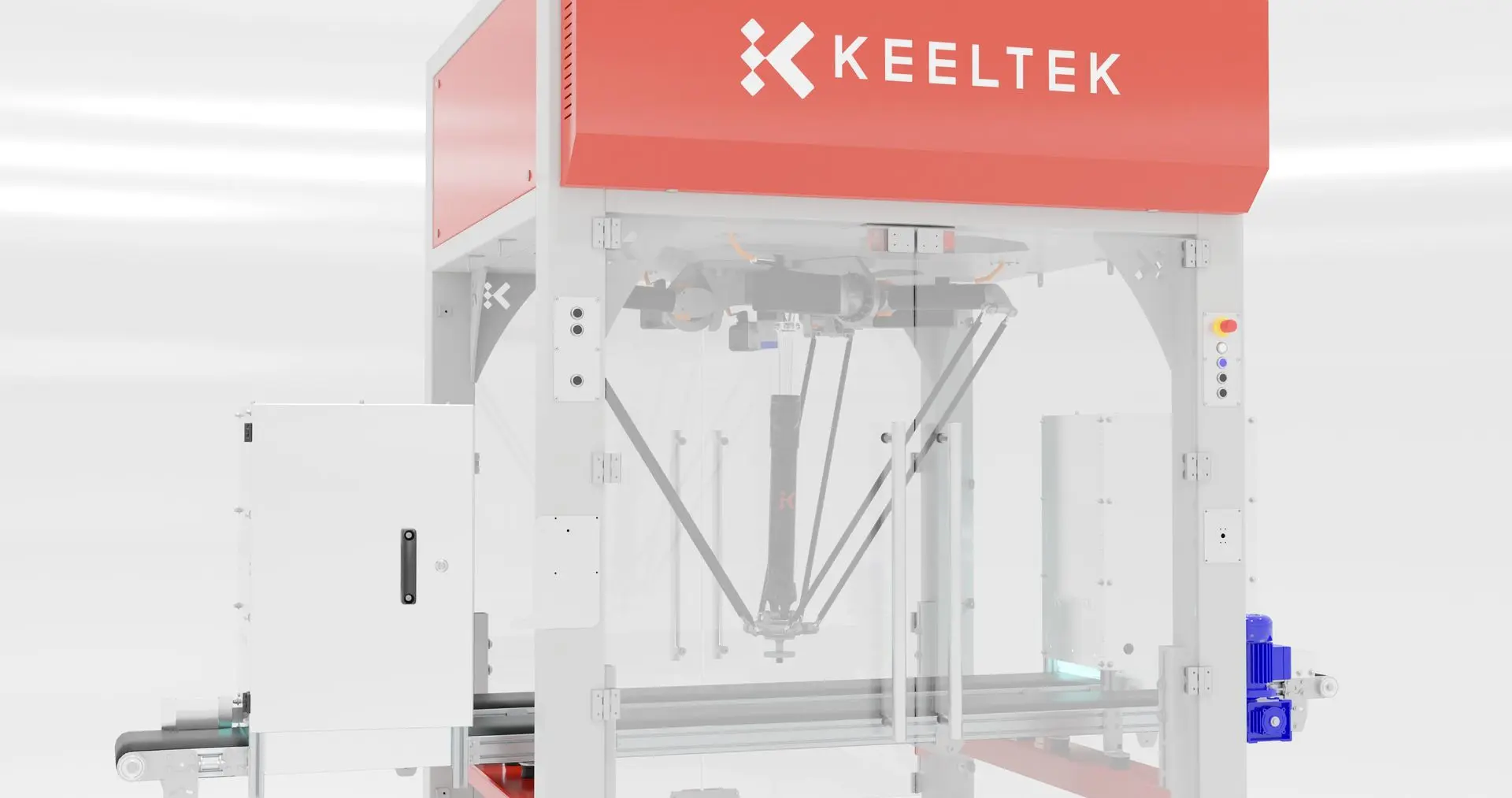

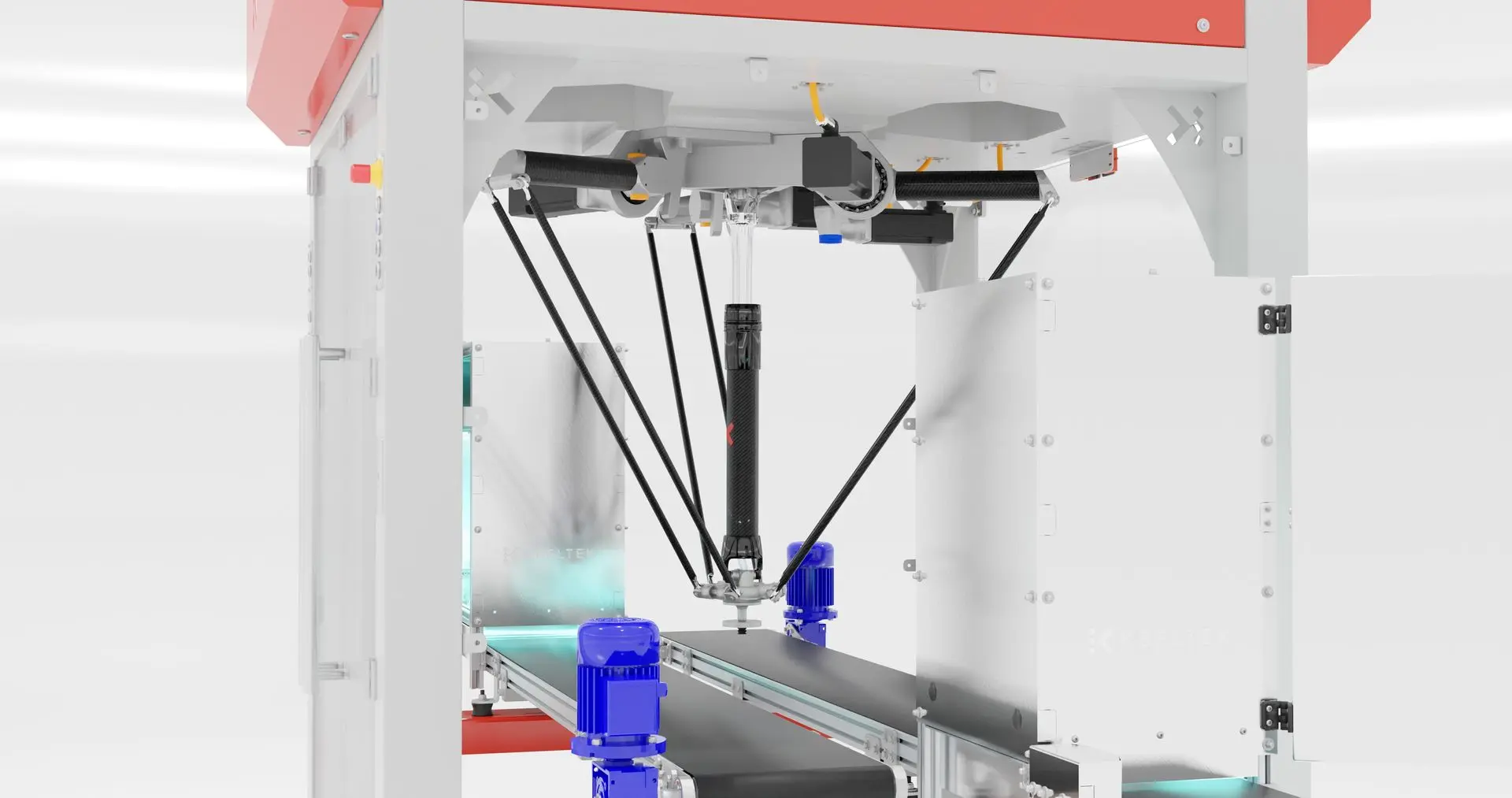

ACCUFAST DELTA

DELTA-type robotic cell

Robotic cell equipped with a DELTA-type robot for high-speed pick-and-place applications with maximum precision.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry Pharmacy

ACCUFAST DELTA

DELTA-type robotic cell

Robotic cell equipped with a DELTA-type robot for high-speed pick-and-place applications with maximum precision.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry Pharmacy

ACCUFAST DELTA

DELTA-type robotic cell

Robotic cell equipped with a DELTA-type robot for high-speed pick-and-place applications with maximum precision.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry Pharmacy

ACCUFAST DELTA

DELTA-type robotic cell

Robotic cell equipped with a DELTA-type robot for high-speed pick-and-place applications with maximum precision.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry Pharmacy

ACCUFAST DELTA

DELTA-type robotic cell

Robotic cell equipped with a DELTA-type robot for high-speed pick-and-place applications with maximum precision.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry Pharmacy

ACCUFAST DELTA

DELTA-type robotic cell

Robotic cell equipped with a DELTA-type robot for high-speed pick-and-place applications with maximum precision.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry Pharmacy

Dimensions | Depending on the application. |

| Reference product | Any type of product (cosmetics, fruit, pastries, etc.) |

| Maximum permissible load | Consult |

| Connectivity | LAN. |

| Cadences | Up to 100 cycles per minute per installed module. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

- Automatic tool change

- KTS, remote assistance.

ACCUFAST SCARA

SCARA-type robotic cell

Robotic cell equipped with SCARA robot for high-speed, high-precision pick-and-place applications

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry Pharmacy

ACCUFAST SCARA

SCARA-type robotic cell

Robotic cell equipped with SCARA robot for high-speed, high-precision pick-and-place applications

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry Pharmacy

ACCUFAST SCARA

SCARA-type robotic cell

Robotic cell equipped with SCARA robot for high-speed, high-precision pick-and-place applications

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry Pharmacy

ACCUFAST SCARA

SCARA-type robotic cell

Robotic cell equipped with SCARA robot for high-speed, high-precision pick-and-place applications

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry Pharmacy

ACCUFAST SCARA

SCARA-type robotic cell

Robotic cell equipped with SCARA robot for high-speed, high-precision pick-and-place applications

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry Pharmacy

Dimensions | Depending on the application. |

| Reference product | Any type of product (cosmetics, fruit, pastries, etc.) |

| Maximum permissible load | Consult |

| Connectivity | LAN. |

| Cadences | Up to 80 cycles per minute per installed module. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

- Automatic tool change.

- KTS, remote assistance.

Request information instantly

All this without any obligation