Mobile robotics

Robótica móvil

Mobile robotics solutions

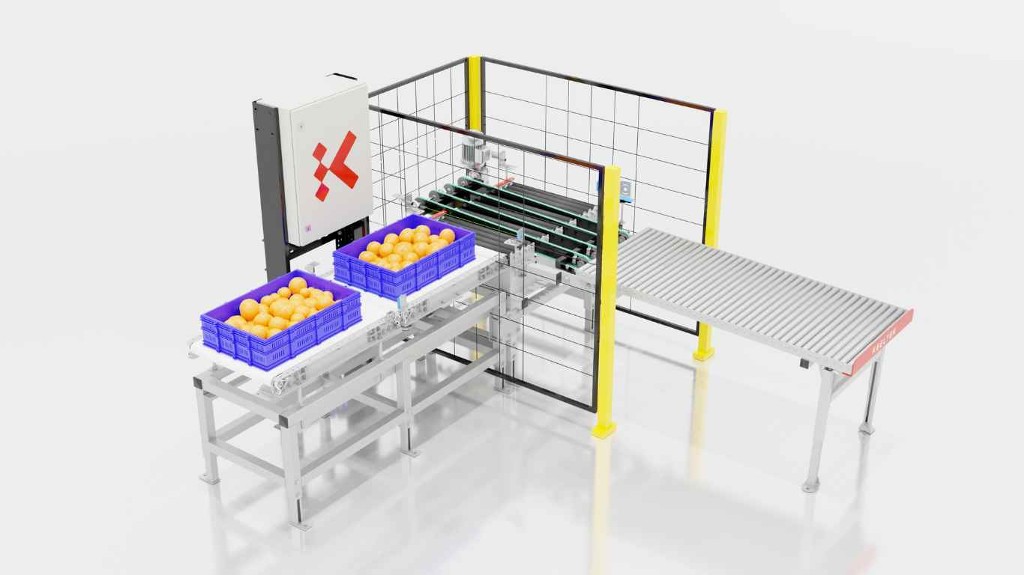

At Keeltek, we offer mobile robotics solutions such as AMRs (Autonomous Mobile Robots) designed to transform logistics and material handling at every stage of the industrial process. Our systems stand out for their innovation, adaptability, customized fleet design tailored to the customer, and ability to integrate seamlessly into dynamic environments.

Keeltek's mobile robotics solutions ensure efficient, flexible, and scalable workflow, reducing operating times, minimizing errors, and improving productivity by adapting perfectly to the specific needs of each customer in complex industrial environments.

KMR FORKLIFT

Fork-type AMR robot

Keeltek Mobile Robot Forklift (KMR Forklift) is an autonomous mobile robot (AMR) for lifting and transporting loads from and/or to ground level.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

KMR FORKLIFT

Fork-type AMR robot

Keeltek Mobile Robot Forklift (KMR Forklift) is an autonomous mobile robot (AMR) for lifting and transporting loads from and/or to ground level.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

KMR FORKLIFT

Fork-type AMR robot

Keeltek Mobile Robot Forklift (KMR Forklift) is an autonomous mobile robot (AMR) for lifting and transporting loads from and/or to ground level.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

KMR FORKLIFT

Fork-type AMR robot

Keeltek Mobile Robot Forklift (KMR Forklift) is an autonomous mobile robot (AMR) for lifting and transporting loads from and/or to ground level.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

KMR FORKLIFT

Fork-type AMR robot

Keeltek Mobile Robot Forklift (KMR Forklift) is an autonomous mobile robot (AMR) for lifting and transporting loads from and/or to ground level.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

KMR FORKLIFT

Fork-type AMR robot

Keeltek Mobile Robot Forklift (KMR Forklift) is an autonomous mobile robot (AMR) for lifting and transporting loads from and/or to ground level.

Perfect for the following sectors:

Químico Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

| Load |

Up to 1,400 kg |

| Reference product |

Pallets or any similar platform |

| Positioning accuracy | <10 mm |

|

Maximum speed

|

1.5 m/s |

| Default navigation |

Laser |

Autonomy | Up to 6 h |

Maximum allowable inclination angle | Up to 5% |

Flexibility:

- Unlike AGVs with fixed routes, Keeltek's KMRs instantly adapt to changes in the plant layout.

Intuitive integration:

- Its user-friendly control software enables rapid programming, outperforming other AMRs that require specialized personnel, which streamlines implementation in packaging operations.

Enhanced security

- Equipped with advanced sensors and obstacle detection systems, AKMRs ensure safe operations alongside human workers, outperforming AGVs in collaborative environments.

Cost efficiency:

- They offer a fast return on investment (ROI), estimated at 4-6 months, thanks to reduced labor costs and optimized flows, with more economical maintenance than AGVs as they do not depend on fixed infrastructure.

Effortless scalability:

- KMRs allow units to be added or tasks to be reconfigured easily, surpassing other AMRs and AGVs in flexibility to grow with production needs.

Accuracy in repetitive tasks

- They optimize the transport of any product with high precision, reducing errors compared to manual solutions or less adaptable AGVs.

- 3D navigation camera.

- Self-loading

- Fleet integration (expandable).

- Customized software and fleet management.

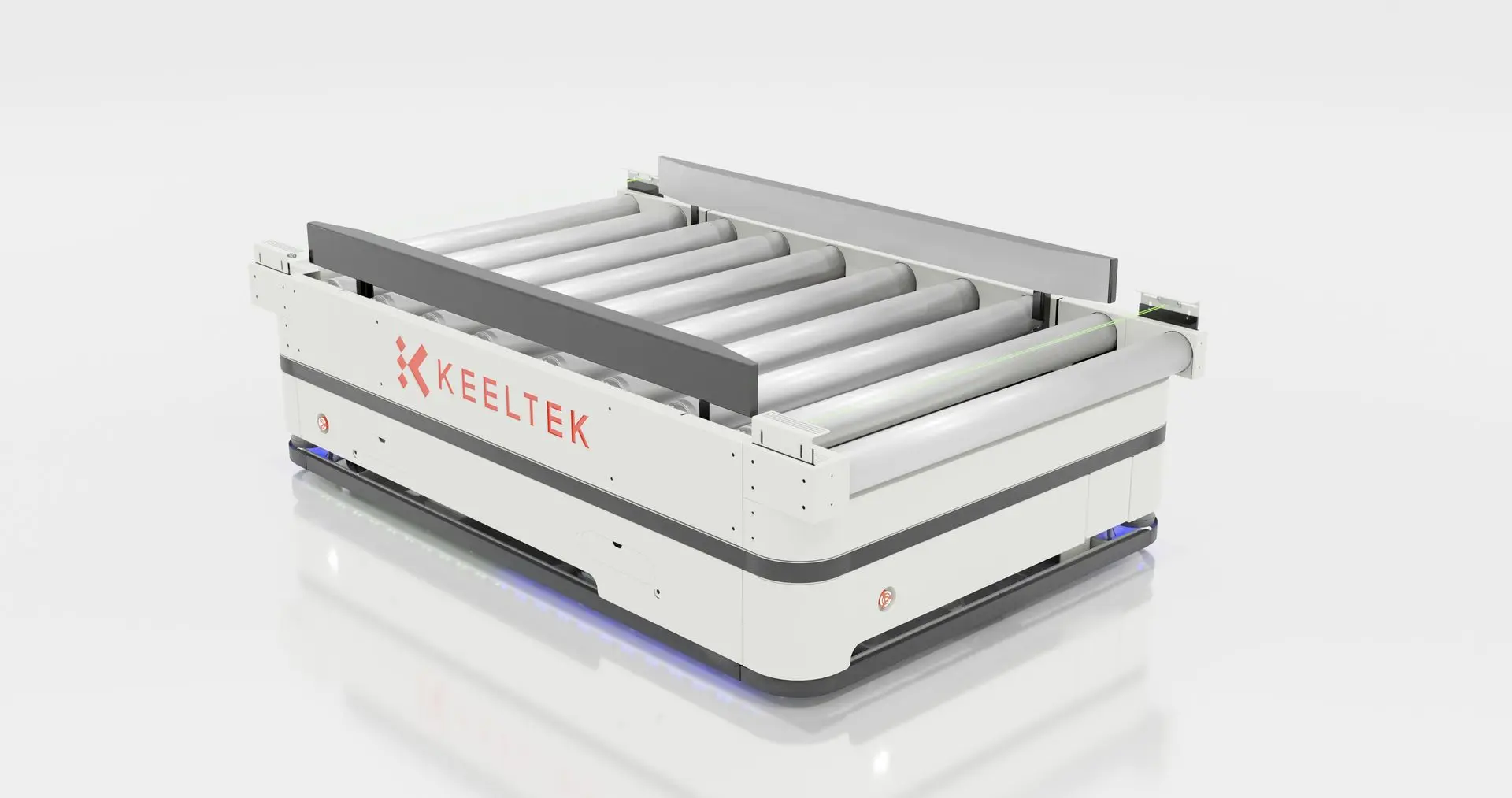

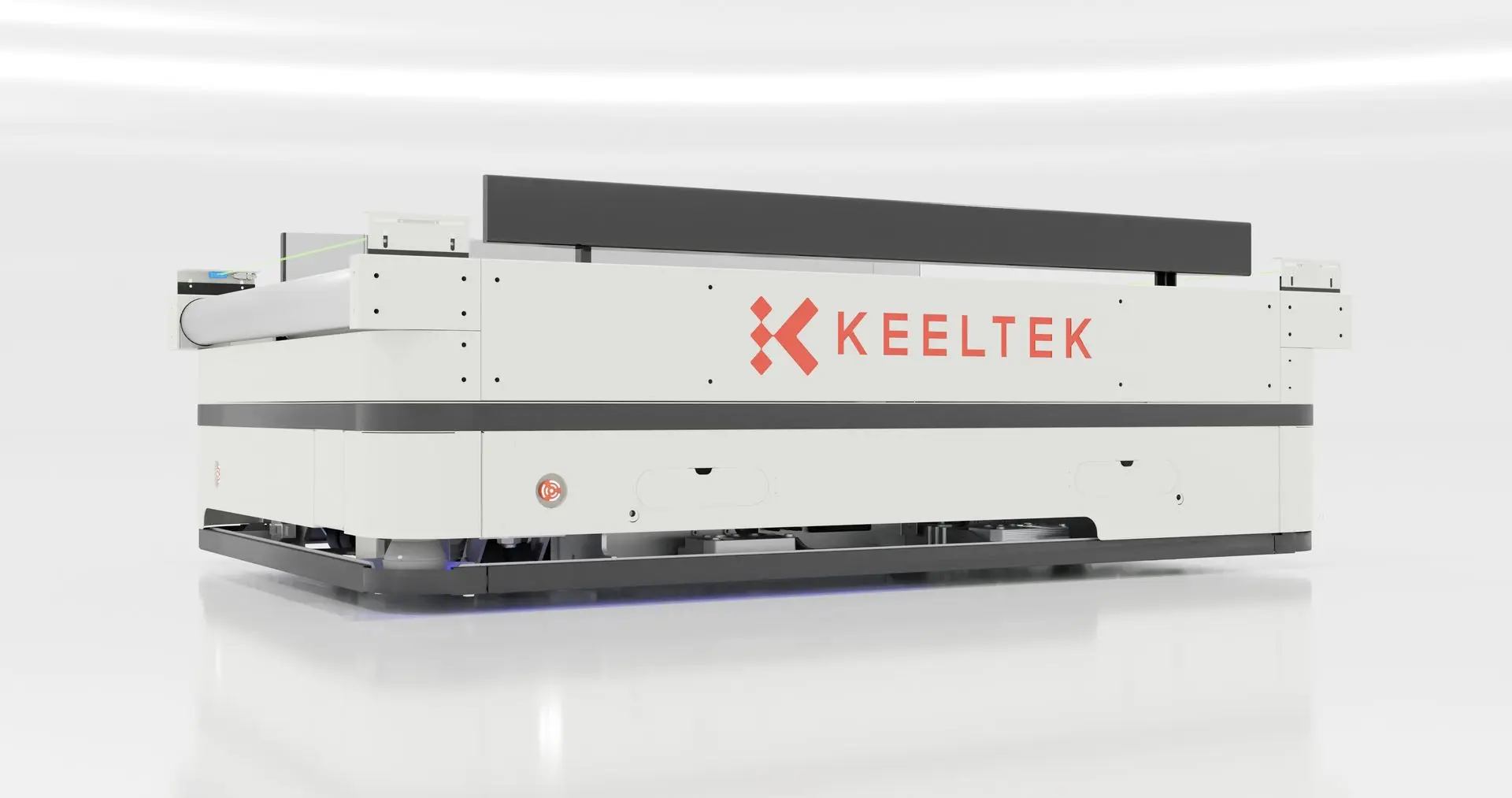

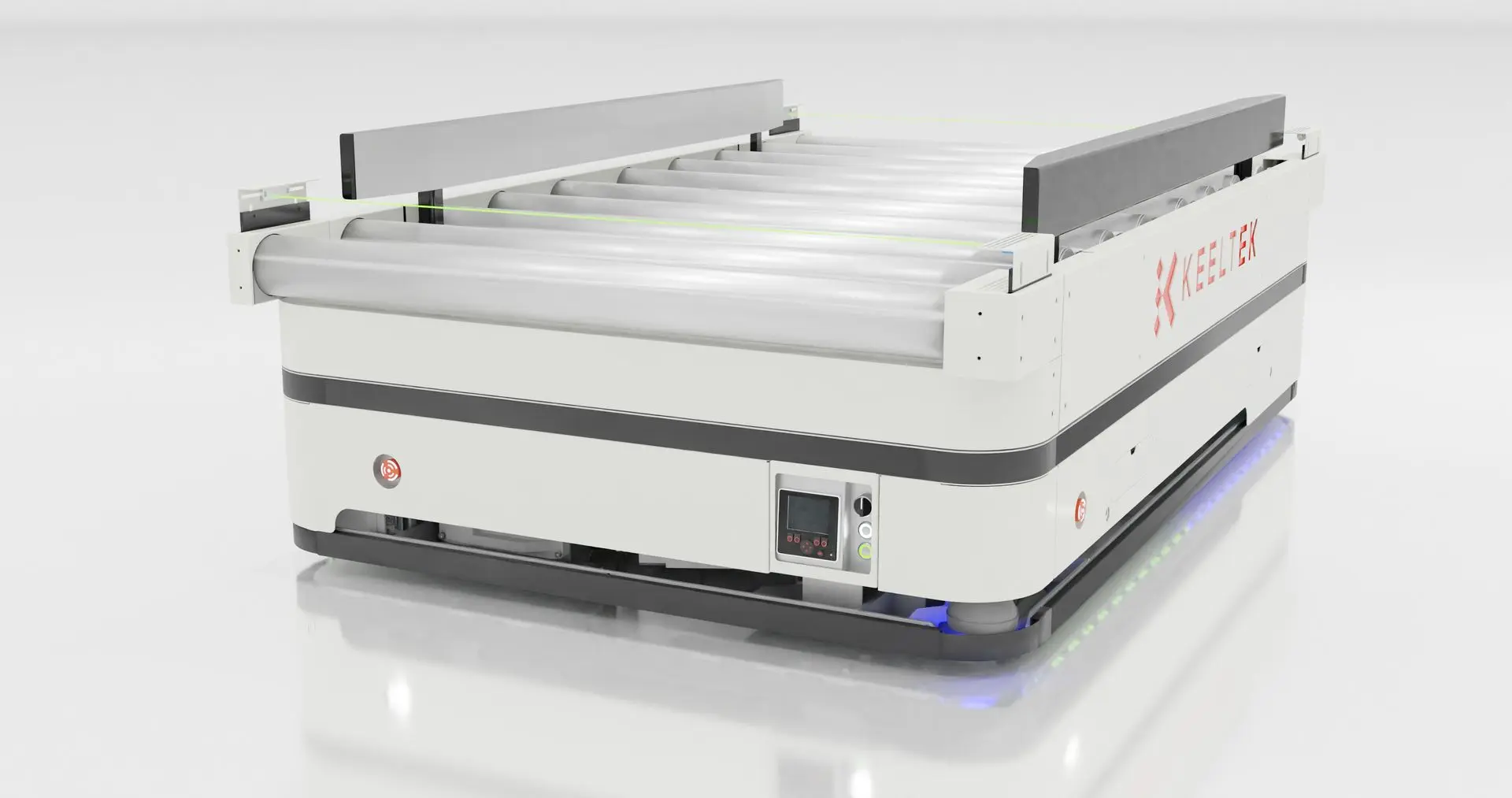

KMR MOUSE

Mouse-type AMR robot

Keeltek Mobile Robot Mouse (KMR Mouse) is an autonomous mobile robot (AMR) for level transport with different configurations.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

KMR MOUSE

Mouse-type AMR robot

Keeltek Mobile Robot Mouse (KMR Mouse) is an autonomous mobile robot (AMR) for level transport with different configurations.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

KMR MOUSE

Mouse-type AMR robot

Keeltek Mobile Robot Mouse (KMR Mouse) is an autonomous mobile robot (AMR) for level transport with different configurations.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

KMR MOUSE

Mouse-type AMR robot

Keeltek Mobile Robot Mouse (KMR Mouse) is an autonomous mobile robot (AMR) for level transport with different configurations.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

KMR MOUSE

Mouse-type AMR robot

Keeltek Mobile Robot Mouse (KMR Mouse) is an autonomous mobile robot (AMR) for level transport with different configurations.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

| Load | Up to 1.500 Kg |

| Reference product |

Any. |

| Positioning accuracy | <10 mm |

|

Maximum speed

|

1.5 m/s |

| Default navigation |

Laser |

Autonomy | Up to 8 h |

Maximum allowable inclination angle | Up to 5% |

Flexibility:

- Unlike AGVs with fixed routes, Keeltek's KMRs instantly adapt to changes in the plant layout.

Intuitive integration:

- Its user-friendly control software enables rapid programming, outperforming other AMRs that require specialized personnel, which streamlines implementation in packaging operations.

Enhanced security:

- Equipped with advanced sensors and obstacle detection systems, AKMRs ensure safe operations alongside human workers, outperforming AGVs in collaborative environments.

Cost efficiency:

- They offer a fast return on investment (ROI), estimated at 4-6 months, thanks to reduced labor costs and optimized flows, with more economical maintenance than AGVs as they do not depend on fixed infrastructure.

Effortless scalability:

- KMRs allow units to be added or tasks to be reconfigured easily, surpassing other AMRs and AGVs in flexibility to grow with production needs.

Accuracy in repetitive tasks:

- They optimize the transport of any product with high precision, reducing errors compared to manual solutions or less adaptable AGVs.

- Different accessories for upper platform: rollers, lift, cobot, etc.

- 3D navigation camera.

- Self-loading

- Fleet integration (expandable).

- Customized software and fleet management.

Request information instantly

All this without any obligation