Turnkey projects

Turnkey projects

Turnkey project solutions

At Keeltek, we offer turnkey projects and composite lines, providing comprehensive and customized solutions to optimize each phase of your production process.

We take care of everything, from design to implementation, ensuring maximum efficiency and alignment with the specific needs of your industrial operation.

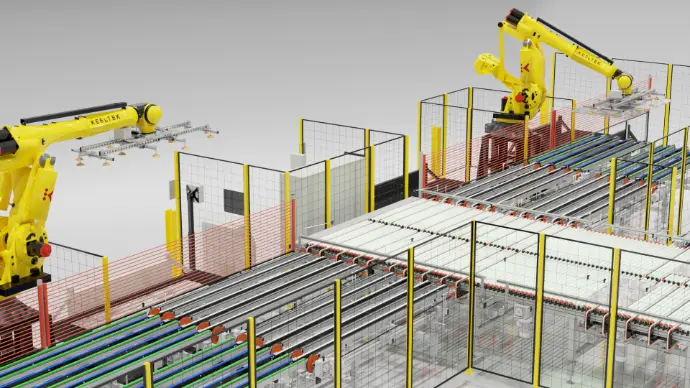

BRIOKOR

Reinforcement line for ceramics

Fully automated line for the automated reinforcement of large XXL ceramic formats and thin ceramic sheets. Reinforcement is carried out using fiberglass, carbon fiber, or similar mesh or fabric and two-component polyurethane adhesives.

Perfect for the following sectors:

Ceramic

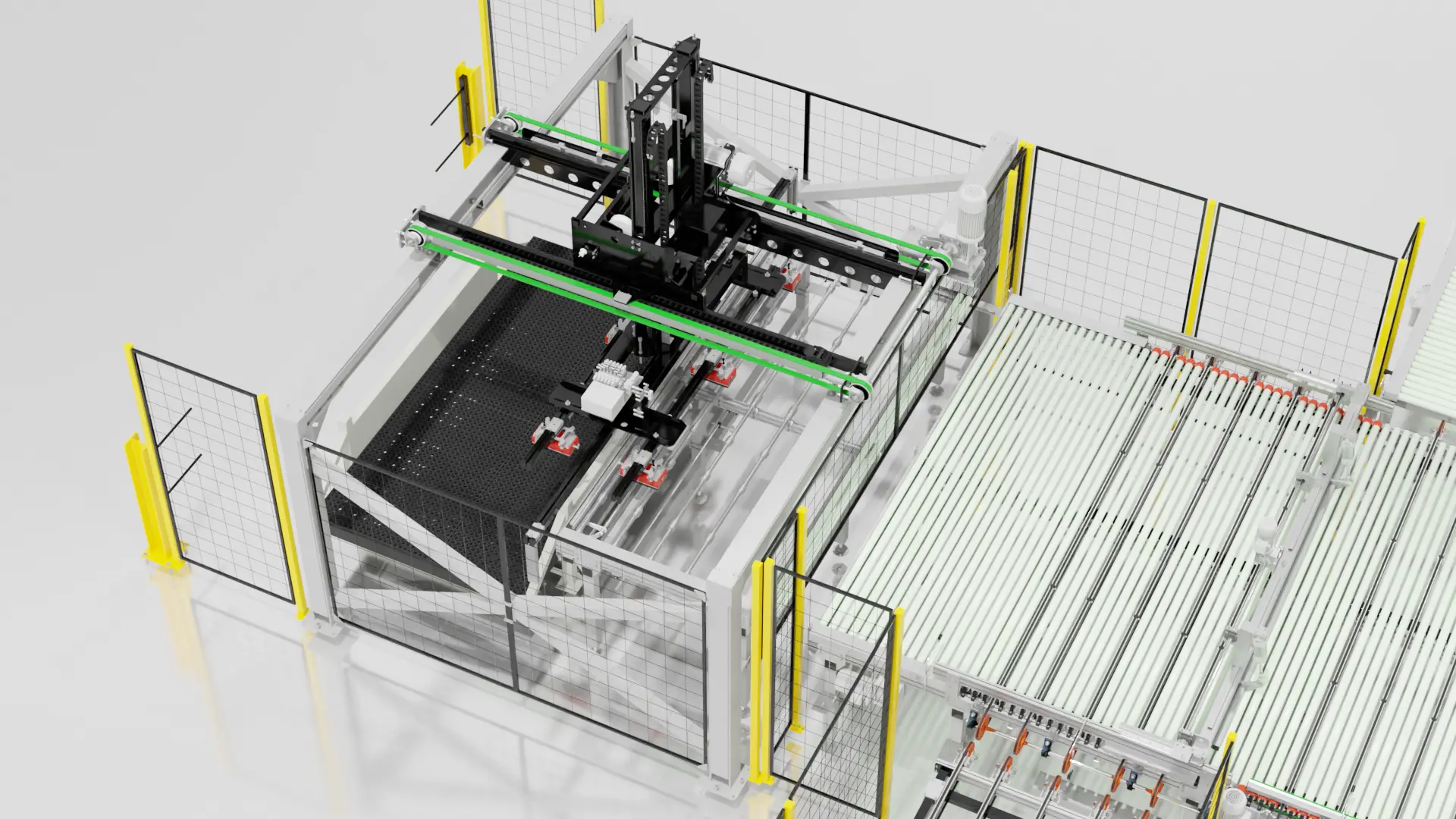

BRIOKOR

Reinforcement line for ceramics

Fully automated line for the automated reinforcement of large XXL ceramic formats and thin ceramic sheets. Reinforcement is carried out using fiberglass, carbon fiber, or similar mesh or fabric and two-component polyurethane adhesives.

Perfect for the following sectors:

Ceramic

BRIOKOR

Reinforcement line for ceramics

Fully automated line for the automated reinforcement of large XXL ceramic formats and thin ceramic sheets. Reinforcement is carried out using fiberglass, carbon fiber, or similar mesh or fabric and two-component polyurethane adhesives.

Perfect for the following sectors:

Ceramic

BRIOKOR

Reinforcement line for ceramics

Fully automated line for the automated reinforcement of large XXL ceramic formats and thin ceramic sheets. Reinforcement is carried out using fiberglass, carbon fiber, or similar mesh or fabric and two-component polyurethane adhesives.

Perfect for the following sectors:

Ceramic

BRIOKOR

Reinforcement line for ceramics

Fully automated line for the automated reinforcement of large XXL ceramic formats and thin ceramic sheets. Reinforcement is carried out using fiberglass, carbon fiber, or similar mesh or fabric and two-component polyurethane adhesives.

Perfect for the following sectors:

Ceramic

BRIOKOR

Reinforcement line for ceramics

Fully automated line for the automated reinforcement of large XXL ceramic formats and thin ceramic sheets. Reinforcement is carried out using fiberglass, carbon fiber, or similar mesh or fabric and two-component polyurethane adhesives.

Perfect for the following sectors:

Ceramic

| Reference product | Virtually any ceramic format or XXL ceramic tile |

| Technology |

PATENTED fiberglass fabric application technology. |

| Maximum permissible load | Consult. |

|

Connectivity

|

LAN. |

| Cadences | Up to 60 pieces/hour |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Safety and ergonomics:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

- Designed with 100% clean electric technology, avoiding the emission of particles into the atmosphere (airbrushing) and CO2 emissions (curing by gas combustion).

Durability:

- Machine manufactured from steel processed by laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Unloading onto pallets or trestles, interchangeable using forklifts (operator management) or AGVs (automated management).

- Possibility of adding robotic loading and/or unloading cells.

- Linear or U-turn configuration.

- KTS, remote assistance.

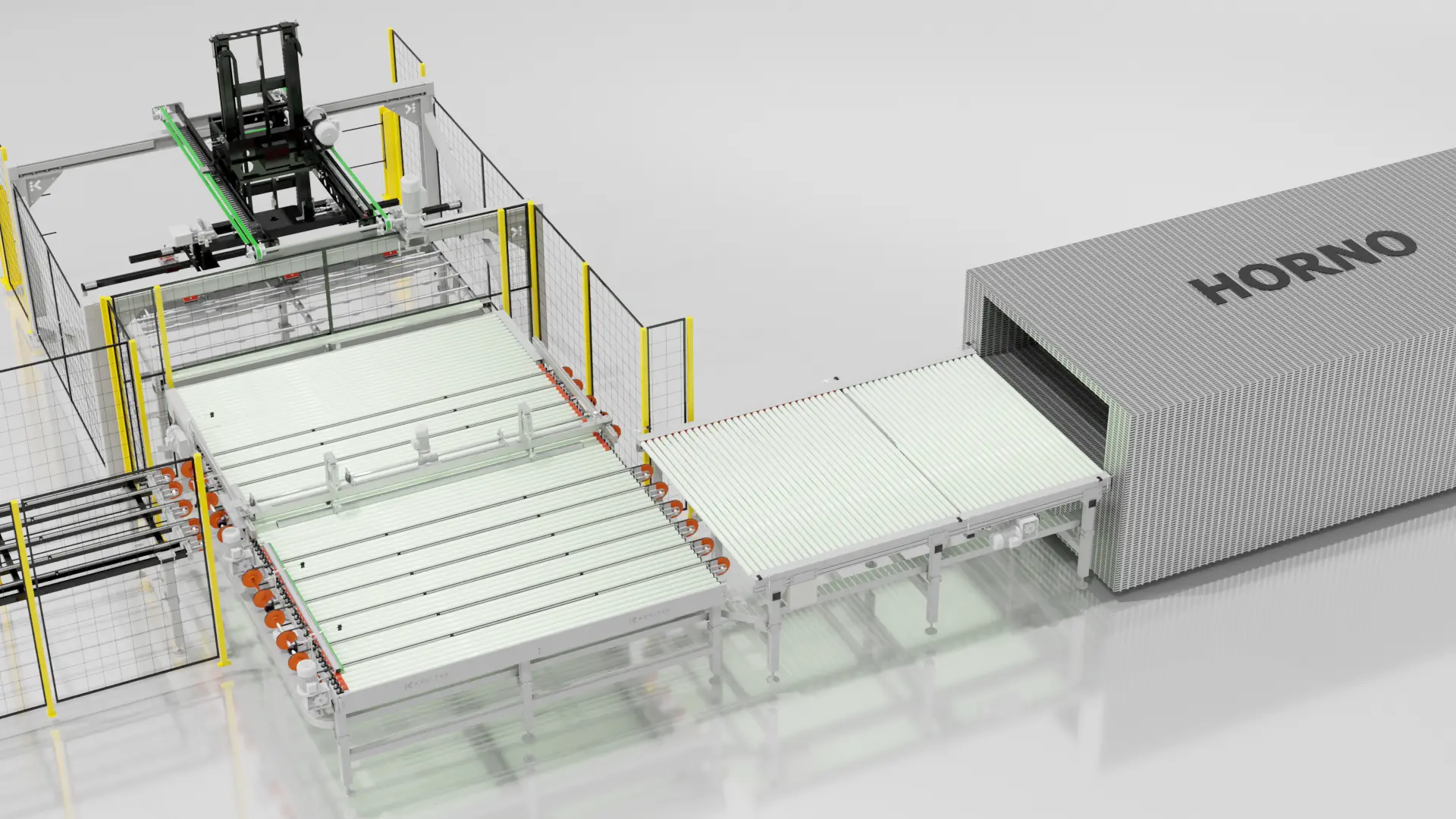

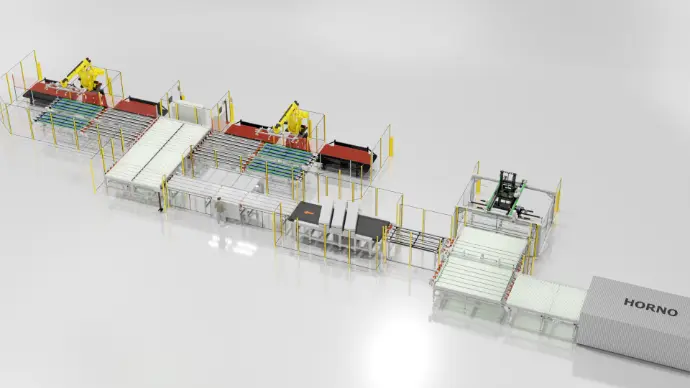

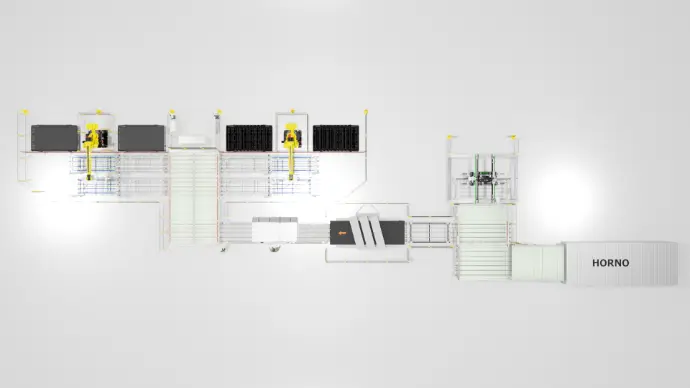

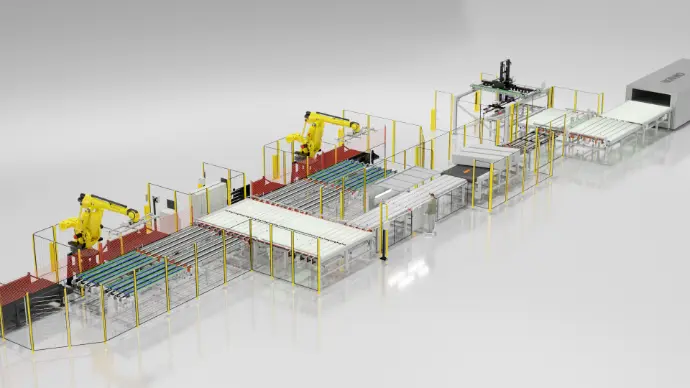

BRIOKOM PLUS

Smart selection line

Ceramic product selection line with semi-automatic visual inspection at the kiln exit. Depending on quality, color, and size, the system unloads them from the line onto the exit support.

Perfect for the following sectors:

Ceramic

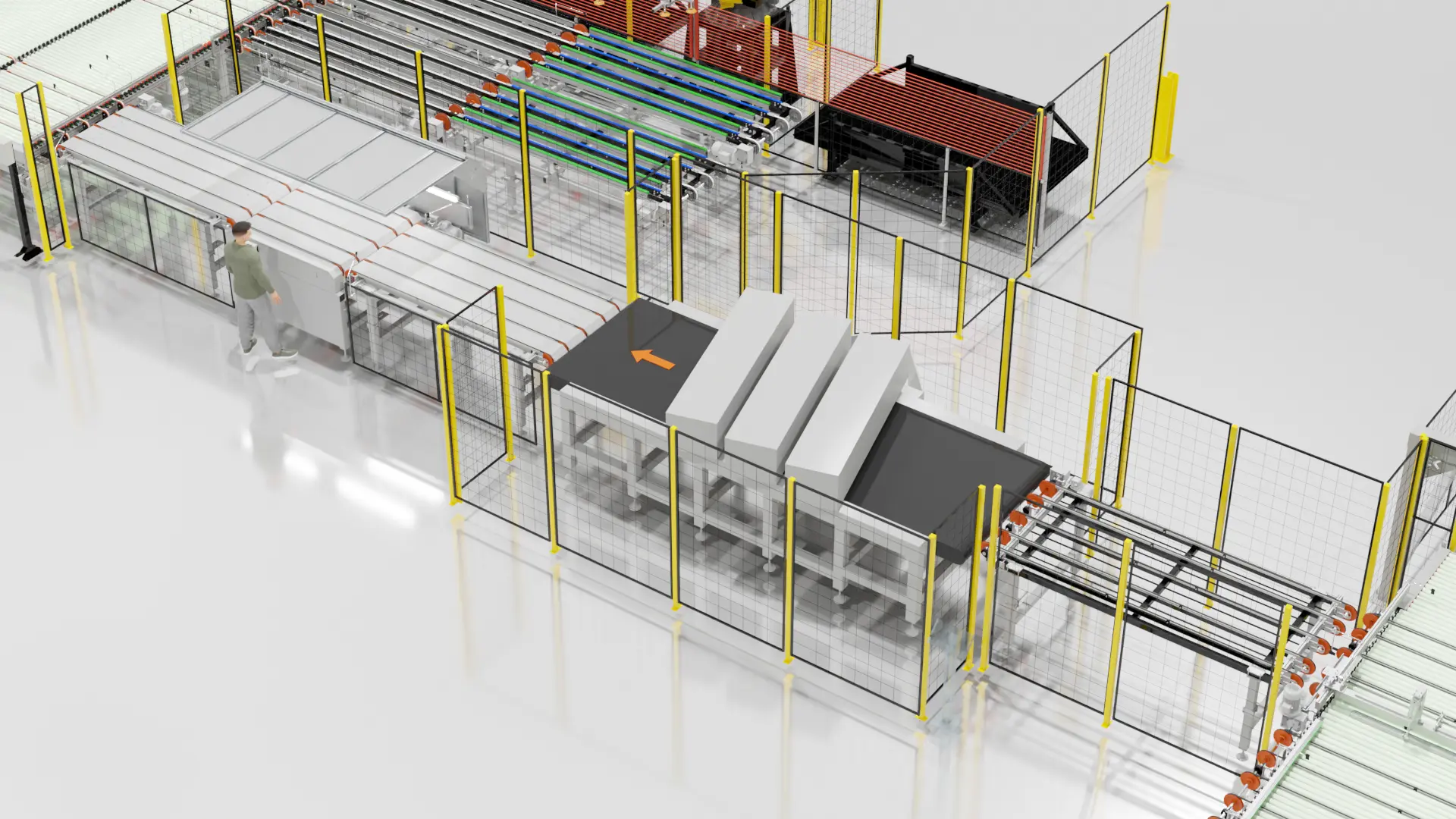

BRIOKOM PLUS

Smart selection line

Ceramic product selection line with semi-automatic visual inspection at the kiln exit. Depending on quality, color, and size, the system unloads them from the line onto the exit support.

Perfect for the following sectors:

Ceramic

BRIOKOM PLUS

Smart selection line

Ceramic product selection line with semi-automatic visual inspection at the kiln exit. Depending on quality, color, and size, the system unloads them from the line onto the exit support.

Perfect for the following sectors:

Ceramic

BRIOKOM PLUS

Smart selection line

Ceramic product selection line with semi-automatic visual inspection at the kiln exit. Depending on quality, color, and size, the system unloads them from the line onto the exit support.

Perfect for the following sectors:

Ceramic

BRIOKOM PLUS

Smart selection line

Ceramic product selection line with semi-automatic visual inspection at the kiln exit. Depending on quality, color, and size, the system unloads them from the line onto the exit support.

Perfect for the following sectors:

Ceramic

BRIOKOM PLUS

Smart selection line

Ceramic product selection line with semi-automatic visual inspection at the kiln exit. Depending on quality, color, and size, the system unloads them from the line onto the exit support.

Perfect for the following sectors:

Ceramic

BRIOKOM PLUS

Smart selection line

Ceramic product selection line with semi-automatic visual inspection at the kiln exit. Depending on quality, color, and size, the system unloads them from the line onto the exit support.

Perfect for the following sectors:

Ceramic

BRIOKOM PLUS

Smart selection line

Ceramic product selection line with semi-automatic visual inspection at the kiln exit. Depending on quality, color, and size, the system unloads them from the line onto the exit support.

Perfect for the following sectors:

Ceramic

BRIOKOM PLUS

Smart selection line

Ceramic product selection line with semi-automatic visual inspection at the kiln exit. Depending on quality, color, and size, the system unloads them from the line onto the exit support.

Perfect for the following sectors:

Ceramic

BRIOKOM PLUS

Smart selection line

Ceramic product selection line with semi-automatic visual inspection at the kiln exit. Depending on quality, color, and size, the system unloads them from the line onto the exit support.

Perfect for the following sectors:

Ceramic

BRIOKOM PLUS

Smart selection line

Ceramic product selection line with semi-automatic visual inspection at the kiln exit. Depending on quality, color, and size, the system unloads them from the line onto the exit support.

Perfect for the following sectors:

Ceramic

BRIOKOM PLUS

Smart selection line

Ceramic product selection line with semi-automatic visual inspection at the kiln exit. Depending on quality, color, and size, the system unloads them from the line onto the exit support.

Perfect for the following sectors:

Ceramic

BRIOKOM PLUS

Smart selection line

Ceramic product selection line with semi-automatic visual inspection at the kiln exit. Depending on quality, color, and size, the system unloads them from the line onto the exit support.

Perfect for the following sectors:

Ceramic

| Reference product | Virtually any ceramic format or ceramic sheet, including XXL. |

| Number of outputs | Configurable/scalable. |

| Maximum permissible load | Consult. |

|

Connectivity

|

LAN. |

| Cadences | Consult. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Safety and ergonomics:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed by laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Download to different types of media.

- Design of the line tailored to the size and weight of the parts.

- KTS, remote assistance.

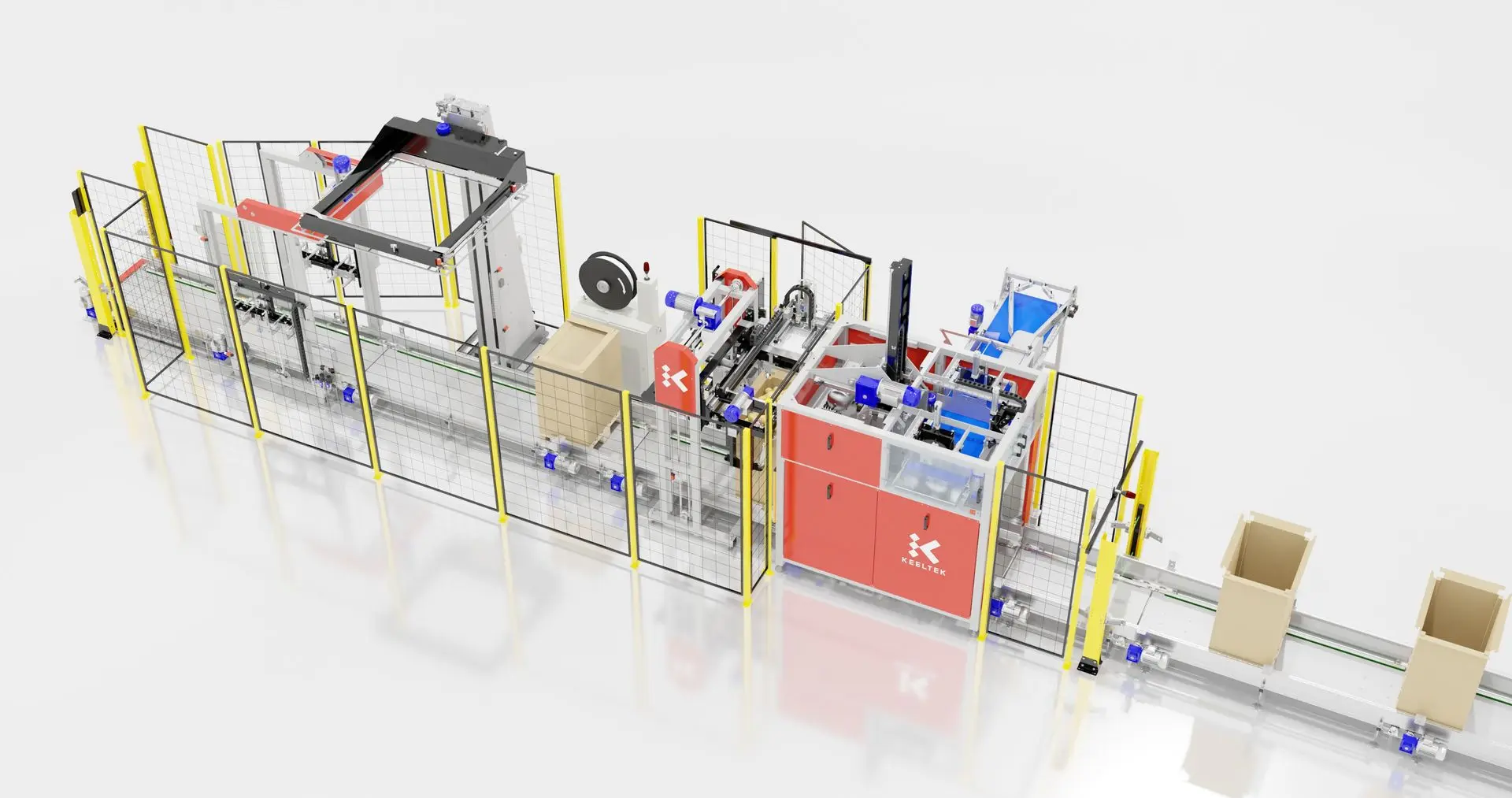

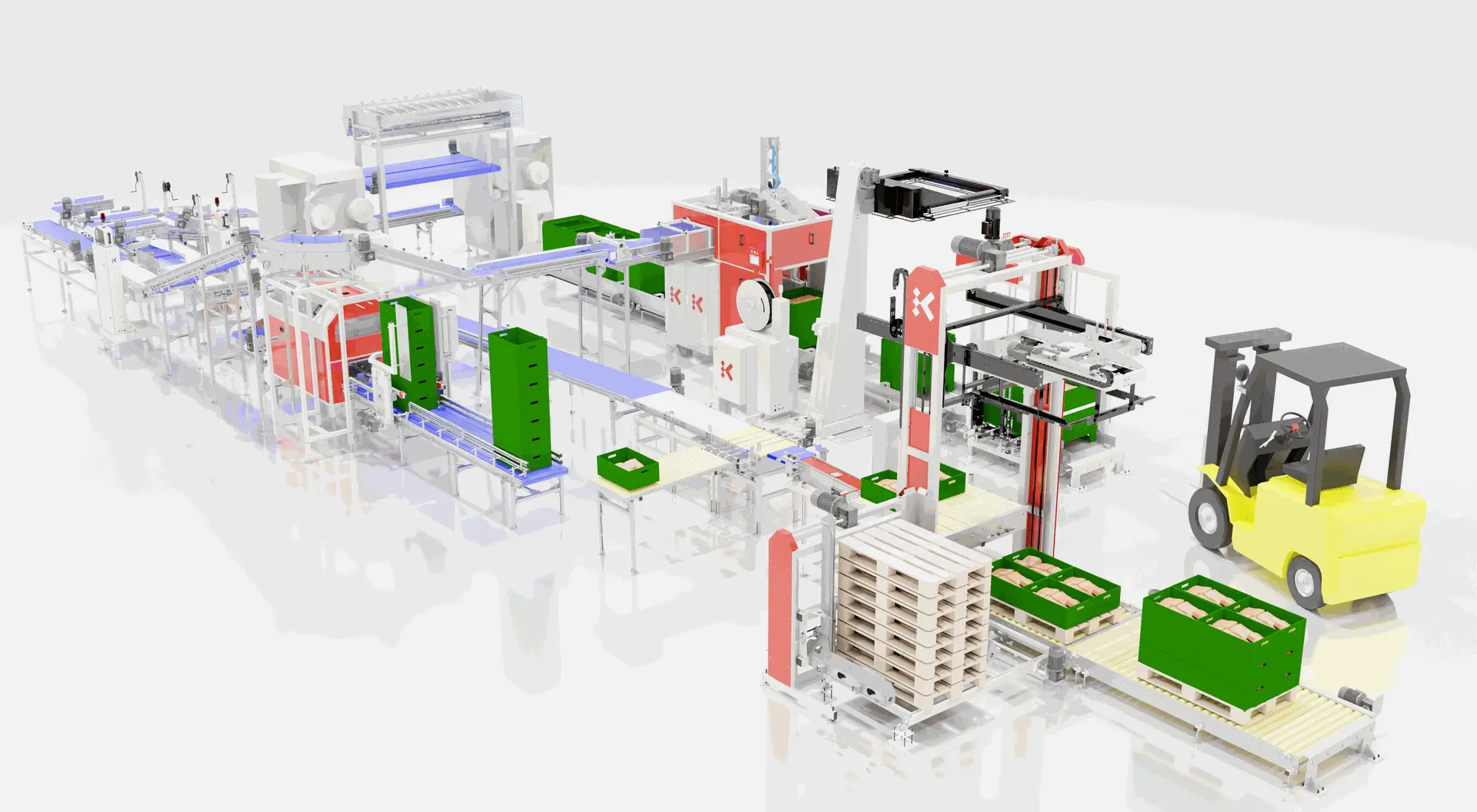

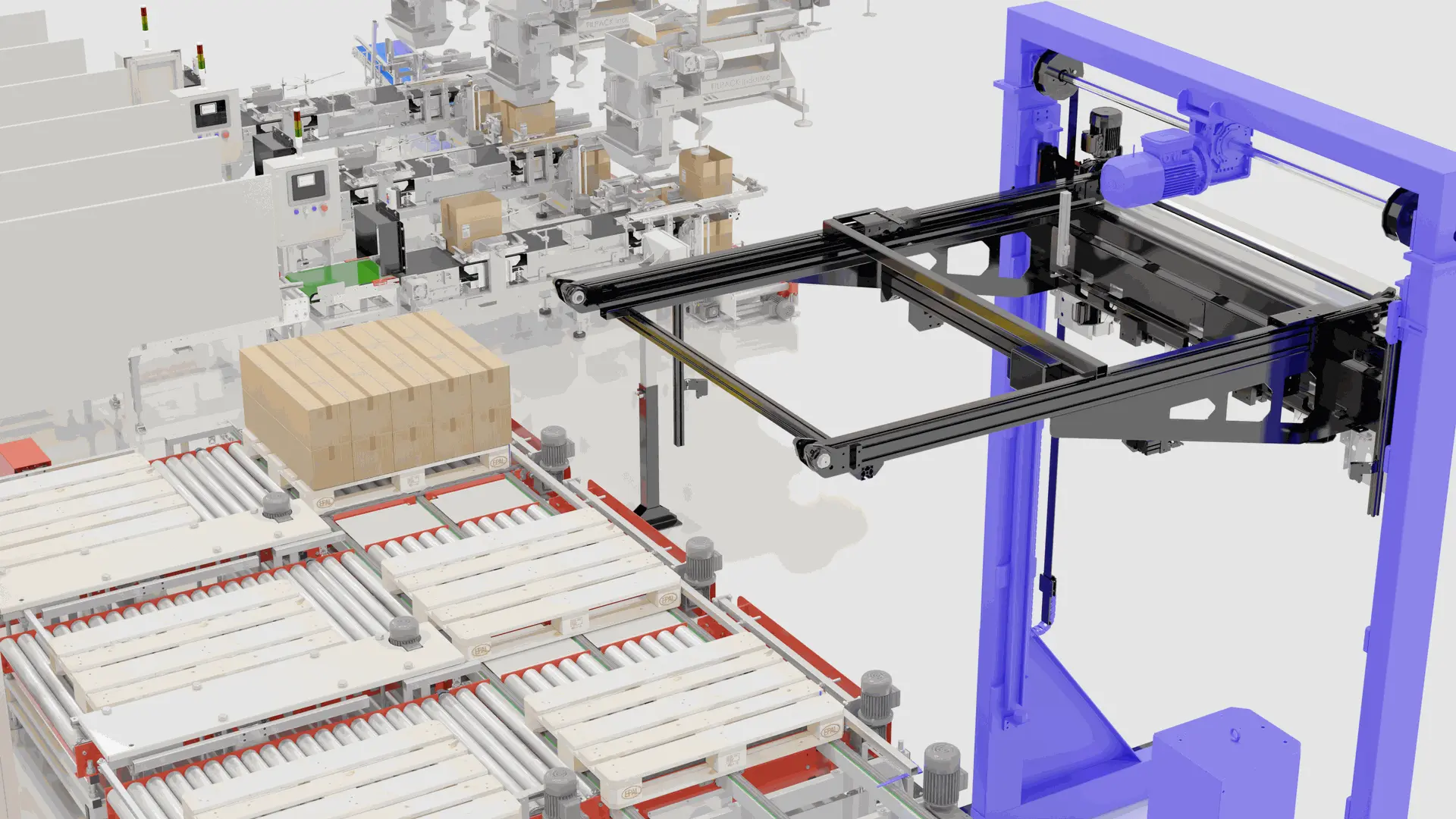

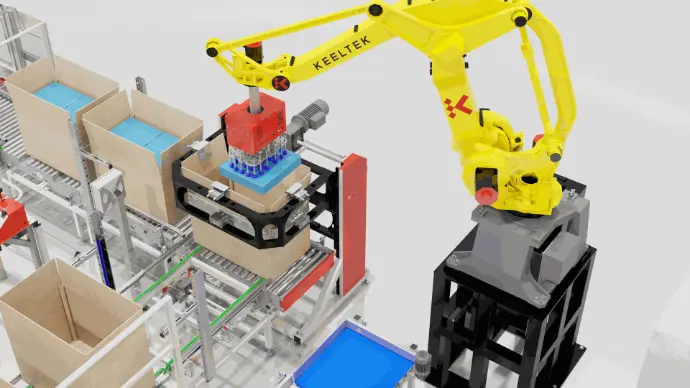

OVERPACK PLUS

Line for overwrapping, sealing, strapping, and stacking boxes

Complete packaging line where the product comes off the line in sack or bag format and the box is filled automatically. The box is completed by placing and sealing the flap, and then the boxes are grouped together for strapping and final palletizing.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry

OVERPACK PLUS

Line for overwrapping, sealing, strapping, and stacking boxes

Complete packaging line where the product comes off the line in sack or bag format and the box is filled automatically. The box is completed by placing and sealing the flap, and then the boxes are grouped together for strapping and final palletizing.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry

OVERPACK PLUS

Line for overwrapping, sealing, strapping, and stacking boxes

Complete packaging line where the product comes off the line in sack or bag format and the box is filled automatically. The box is completed by placing and sealing the flap, and then the boxes are grouped together for strapping and final palletizing.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry

OVERPACK PLUS

Line for overwrapping, sealing, strapping, and stacking boxes

Complete packaging line where the product comes off the line in sack or bag format and the box is filled automatically. The box is completed by placing and sealing the flap, and then the boxes are grouped together for strapping and final palletizing.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry

OVERPACK PLUS

Line for overwrapping, sealing, strapping, and stacking boxes

Complete packaging line where the product comes off the line in sack or bag format and the box is filled automatically. The box is completed by placing and sealing the flap, and then the boxes are grouped together for strapping and final palletizing.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry

| Reference product | Any that needs to be fitted. |

| Box size |

Consult. |

| Output product | Full pallet. |

| Maximum cadence | Consult. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Safety and ergonomics:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed by laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Possibility of using different boxers depending on the size of the box.

- Optional strapping.

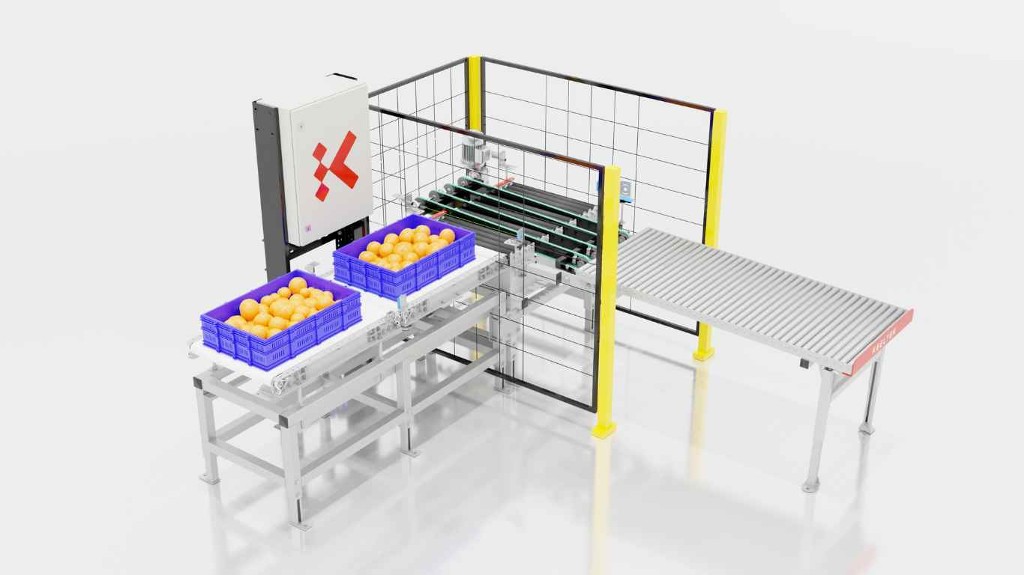

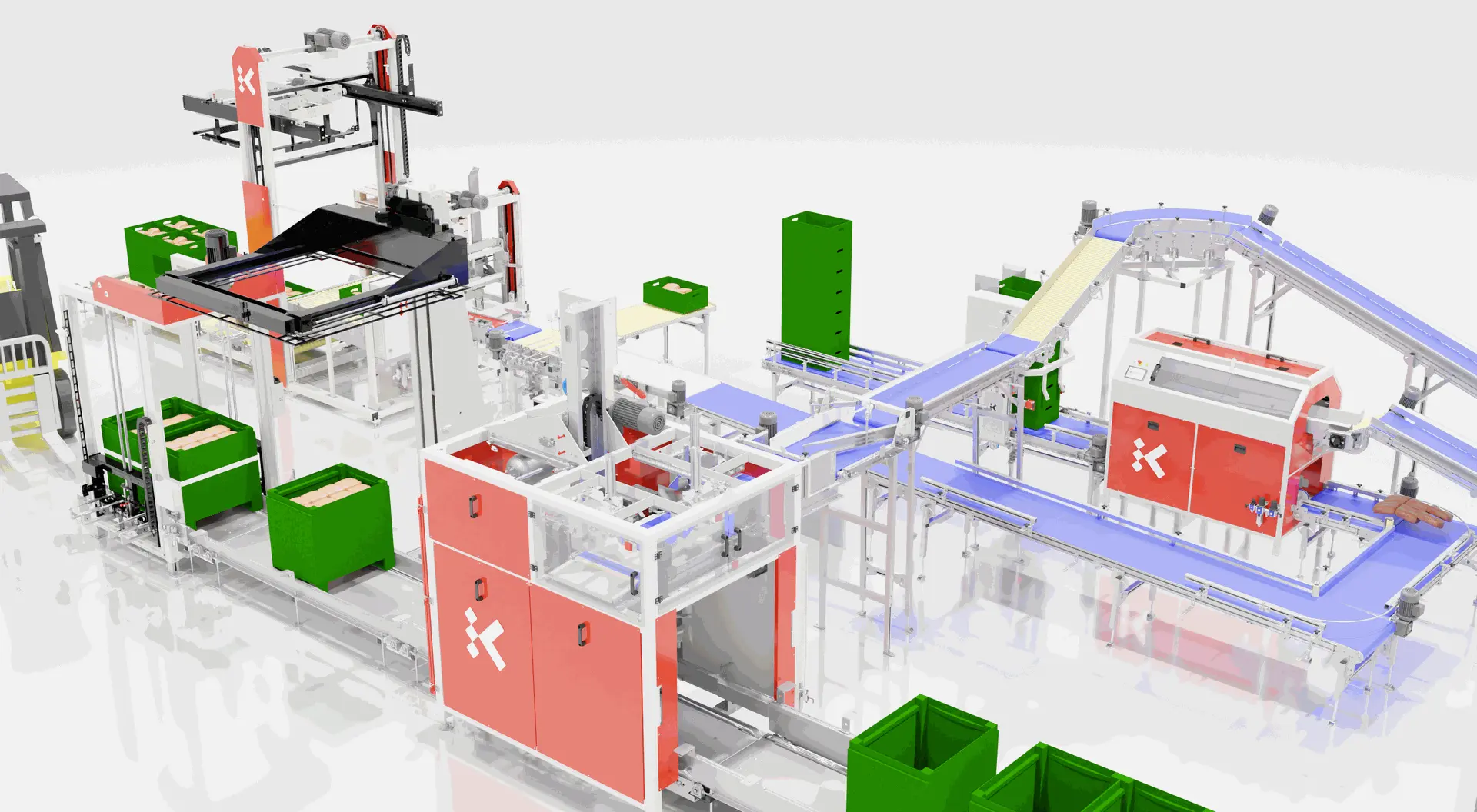

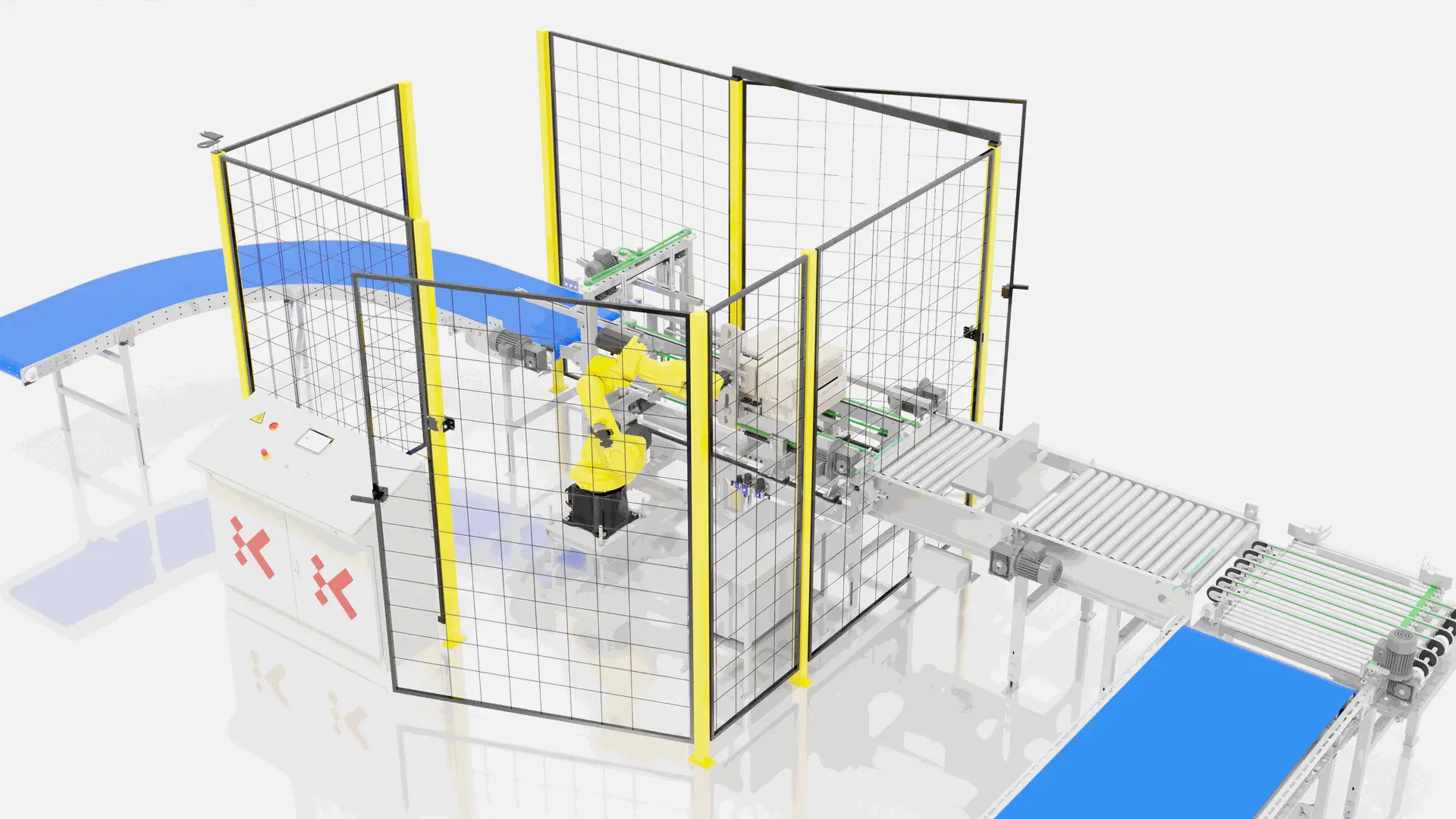

BAGPACKER PLUS

Sack case-packing line

Complete packaging line focused on the fruit and vegetable sector. Starting with the product in bag or sack format, it is packed into different container sizes for dynamic control weighing.

Finally, the containers are grouped according to need for final palletizing.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry

BAGPACKER PLUS

Sack case-packing line

Complete packaging line focused on the fruit and vegetable sector. Starting with the product in bag or sack format, it is packed into different container sizes for dynamic control weighing.

Finally, the containers are grouped according to need for final palletizing.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry

BAGPACKER PLUS

Sack case-packing line

Complete packaging line focused on the fruit and vegetable sector. Starting with the product in bag or sack format, it is packed into different container sizes for dynamic control weighing.

Finally, the containers are grouped according to need for final palletizing.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry

BAGPACKER PLUS

Sack case-packing line

Complete packaging line focused on the fruit and vegetable sector. Starting with the product in bag or sack format, it is packed into different container sizes for dynamic control weighing.

Finally, the containers are grouped according to need for final palletizing.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry

| Reference product | Bag or sack. |

| Output product | Full pallet. |

| Maximum cadence | Consult. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Safety and ergonomics:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed by laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Compatible with different sizes of bags and boxes.

- Configurable cash grouping type.

- Automatic rejection.

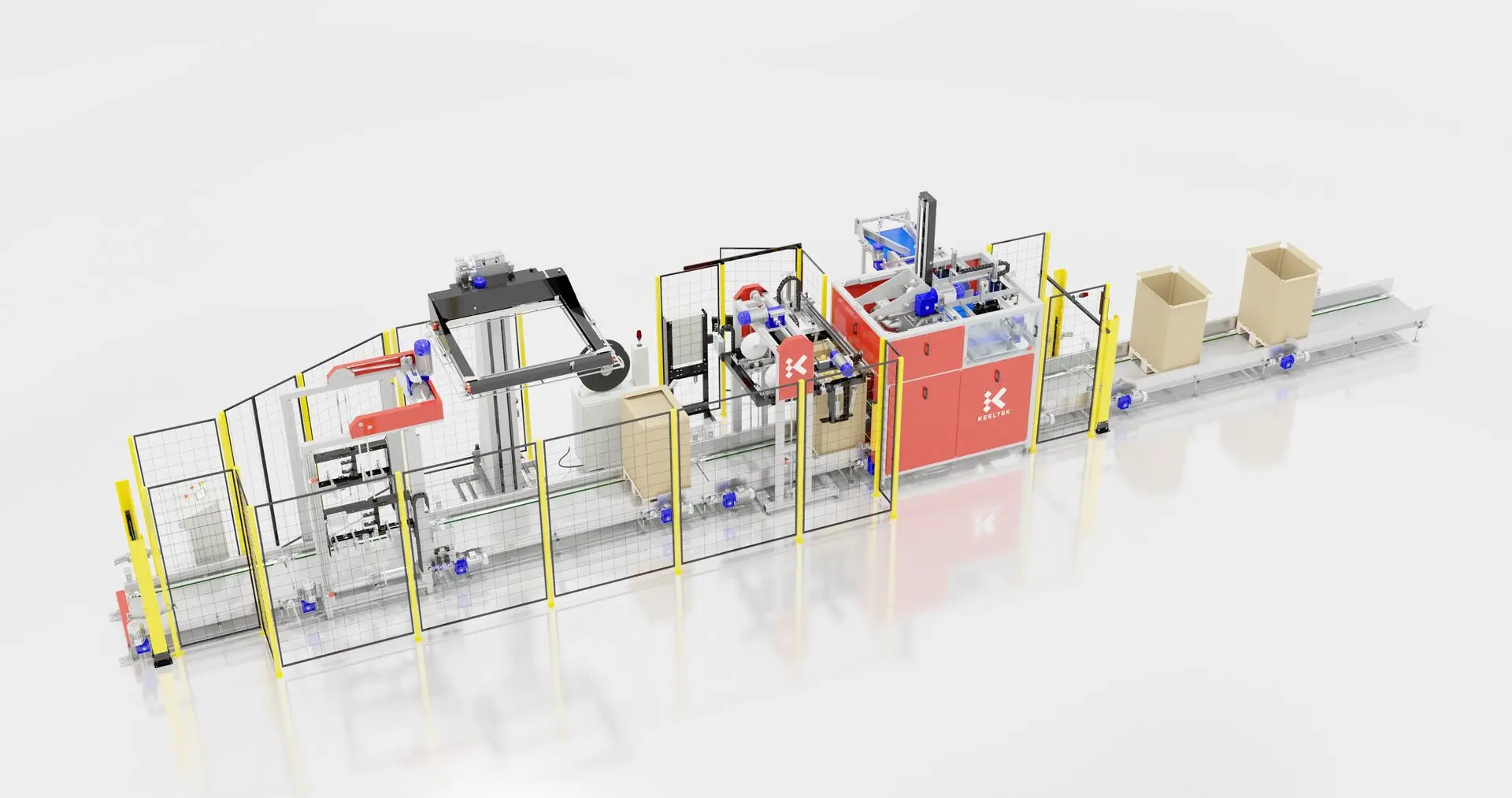

BRIOPAL PLUS

Bulk parts assembly line

Complete line for dosing and filling bulk products into boxes. Includes automatic box closing, weight control, and palletizing for final bundling.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry

BRIOPAL PLUS

Bulk parts assembly line

Complete line for dosing and filling bulk products into boxes. Includes automatic box closing, weight control, and palletizing for final bundling.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry

BRIOPAL PLUS

Bulk parts assembly line

Complete line for dosing and filling bulk products into boxes. Includes automatic box closing, weight control, and palletizing for final bundling.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry

BRIOPAL PLUS

Bulk parts assembly line

Complete line for dosing and filling bulk products into boxes. Includes automatic box closing, weight control, and palletizing for final bundling.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry

BRIOPAL PLUS

Bulk parts assembly line

Complete line for dosing and filling bulk products into boxes. Includes automatic box closing, weight control, and palletizing for final bundling.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry

BRIOPAL PLUS

Bulk parts assembly line

Complete line for dosing and filling bulk products into boxes. Includes automatic box closing, weight control, and palletizing for final bundling.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry

| Reference product | Bulk solids, cardboard box |

| Output product |

Strapped pallet. |

| Maximum cadence | Consult. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Safety and ergonomics:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed by laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Compatible with different types of bulk products.

- Possibility of automatic rejection.

- Wrapped with stretch hood or stretch film.

- Variable box size.

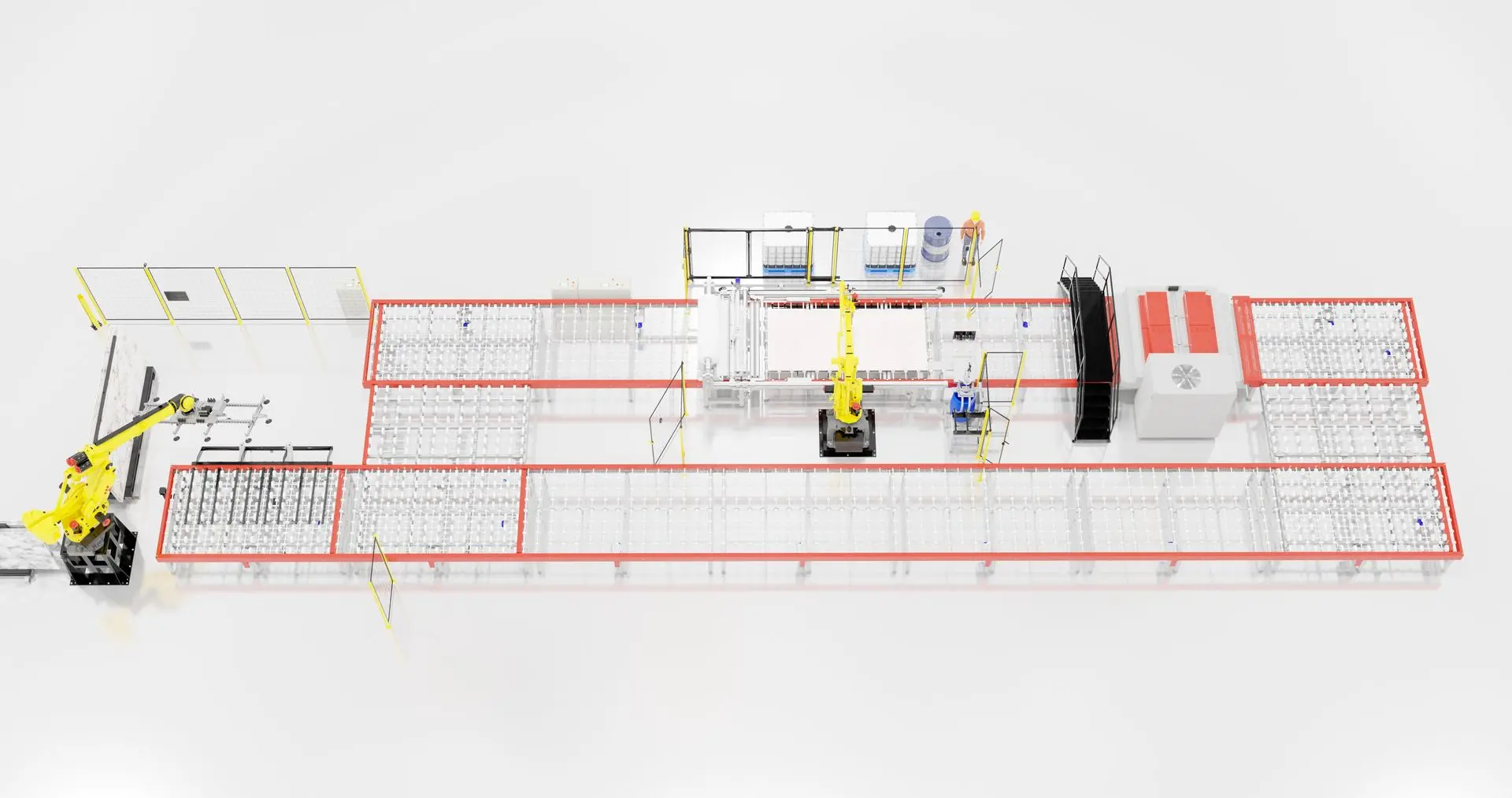

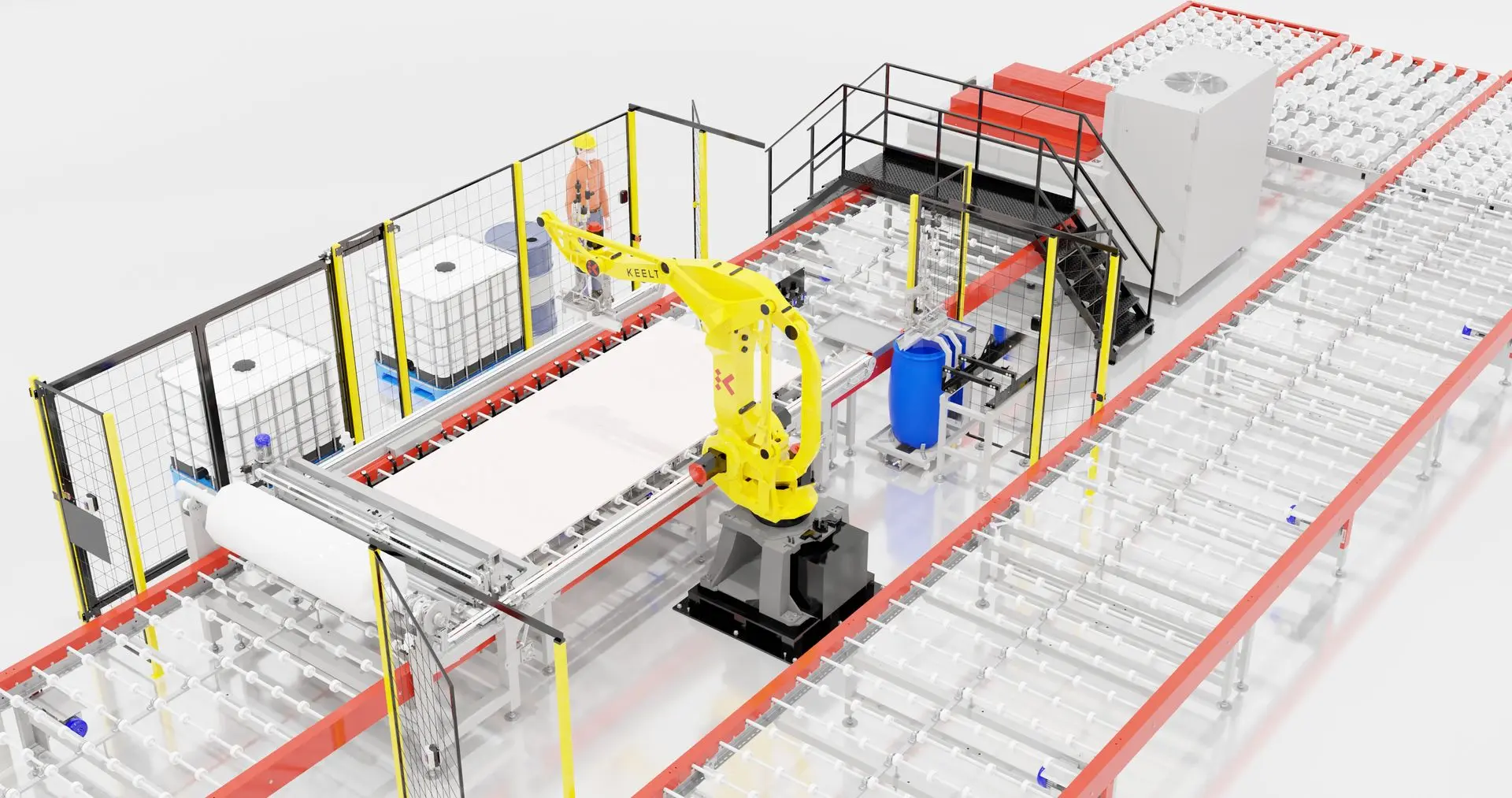

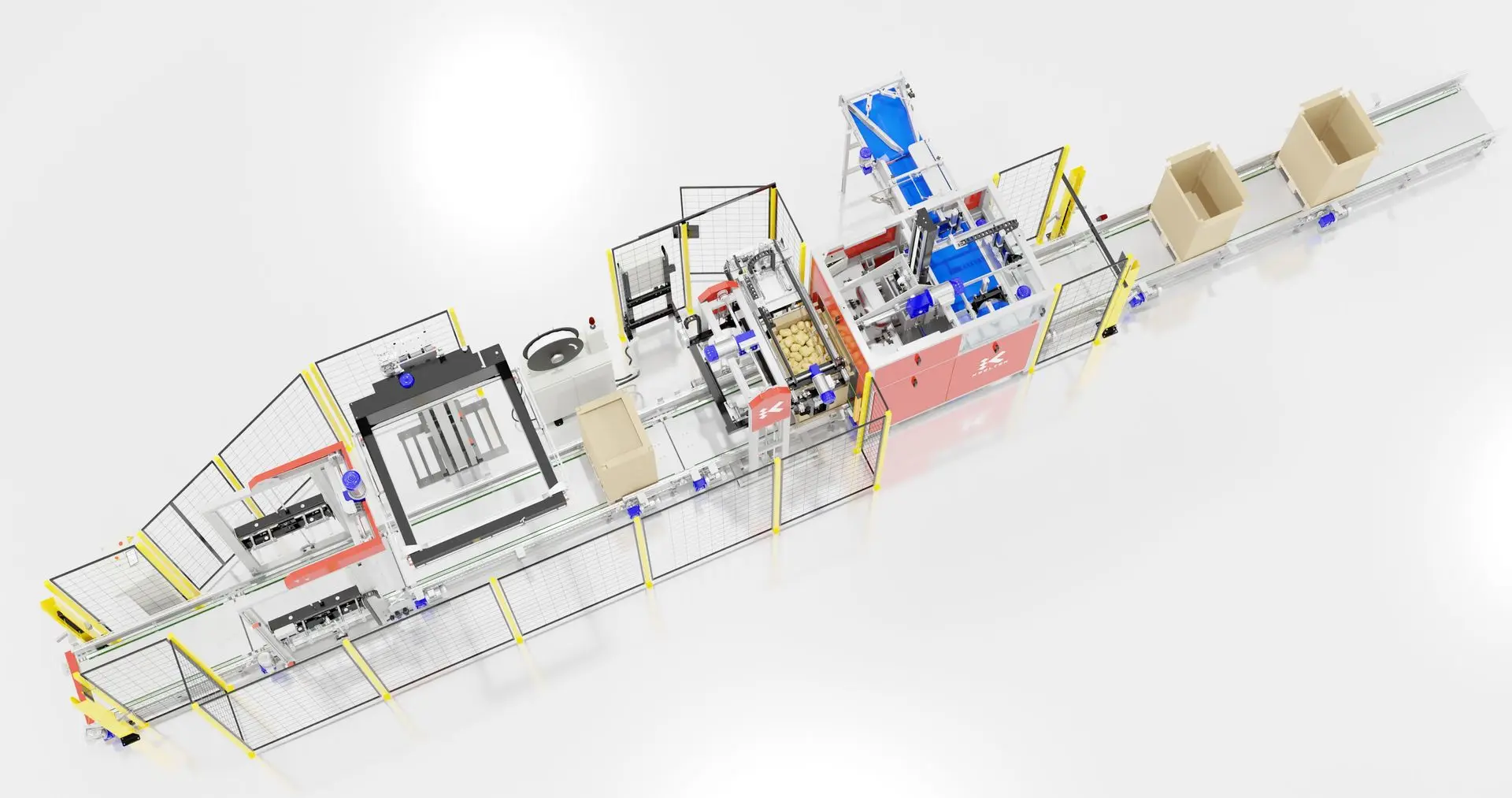

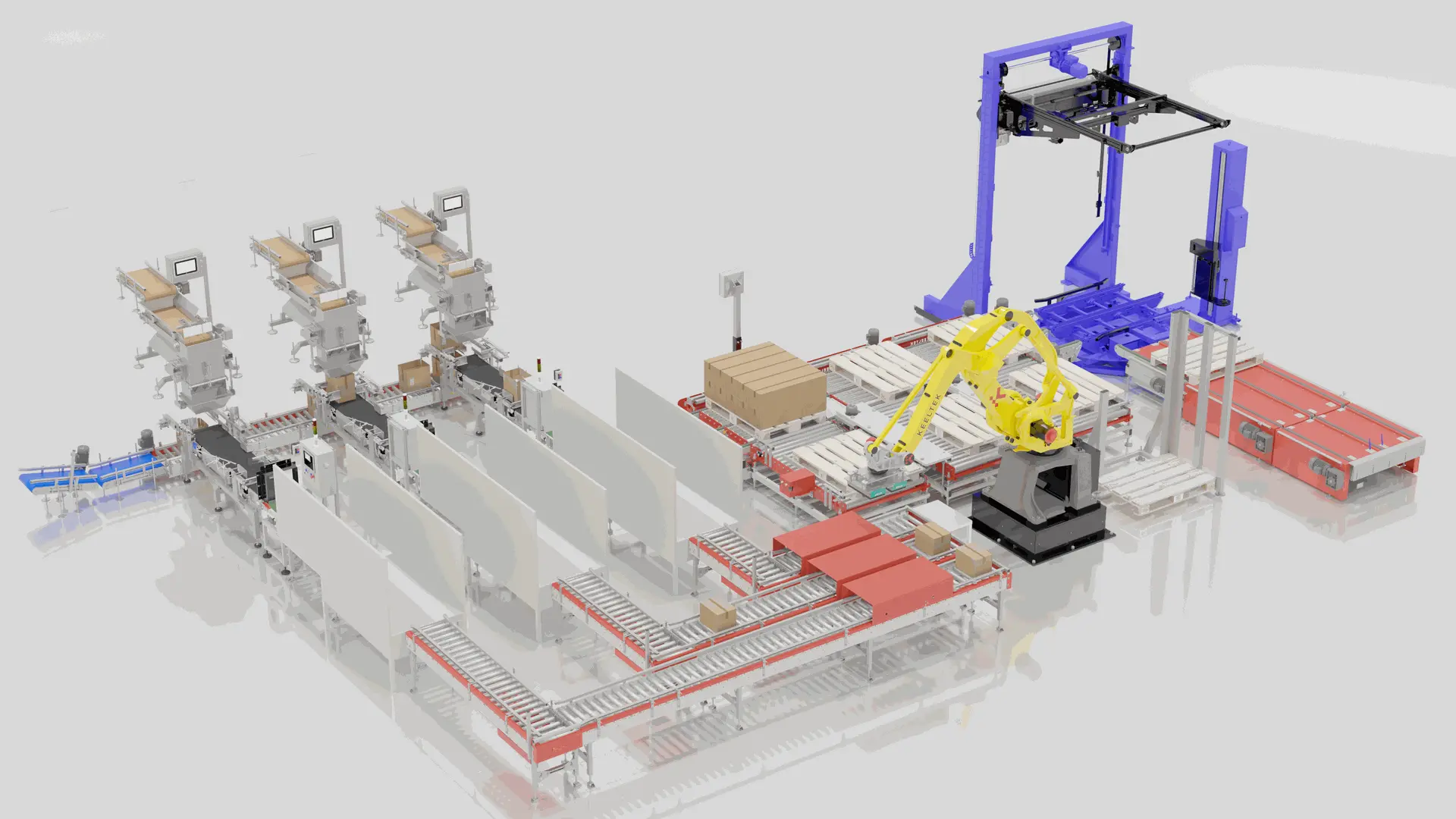

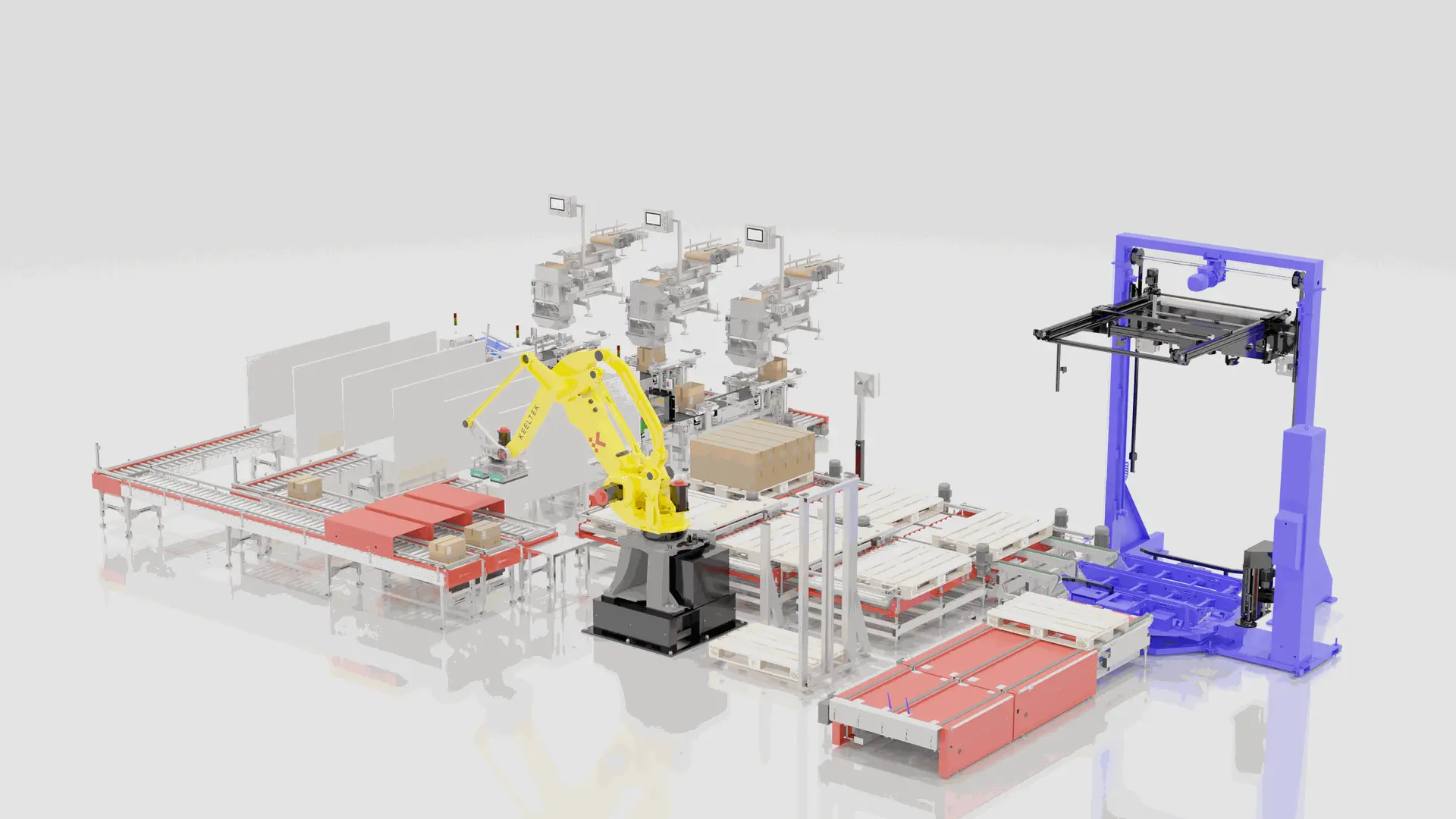

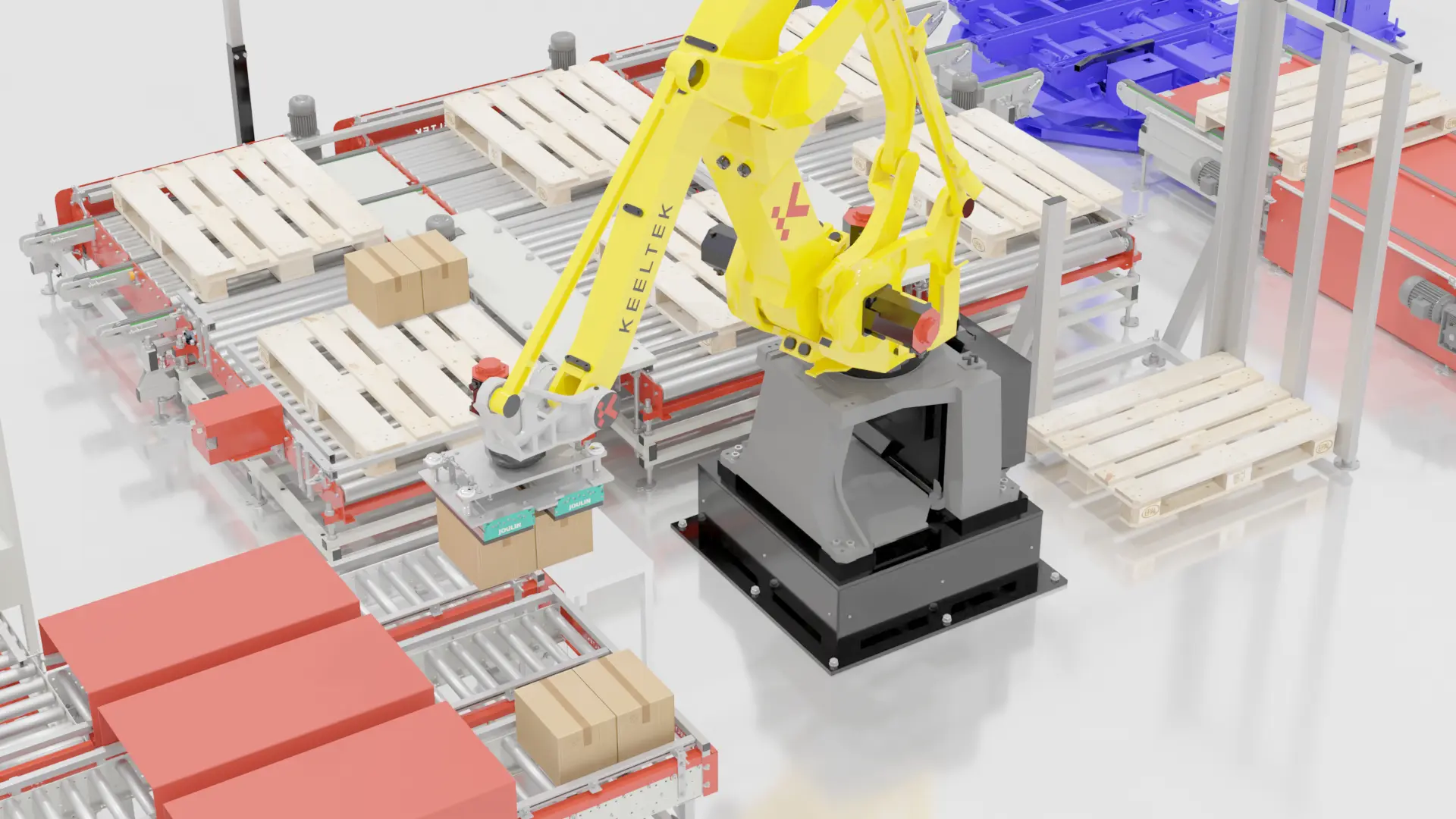

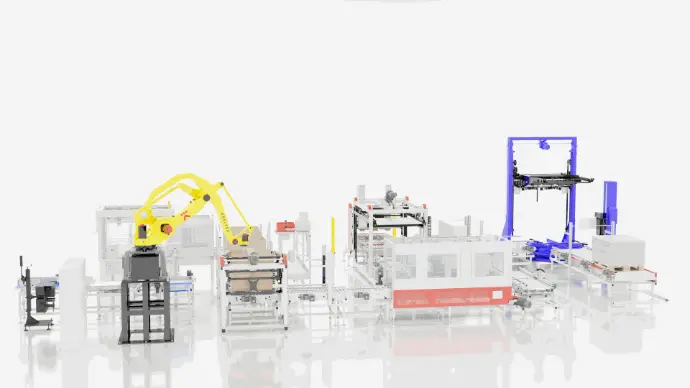

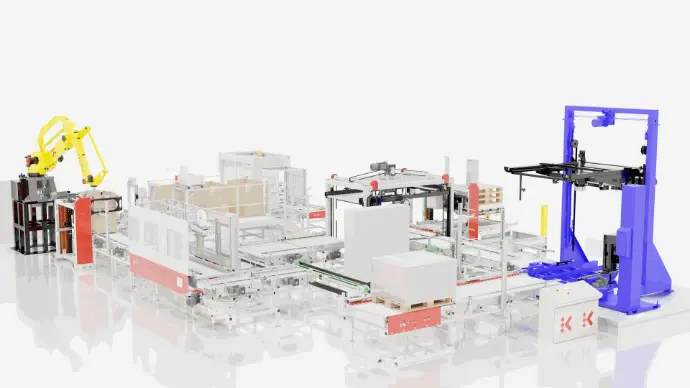

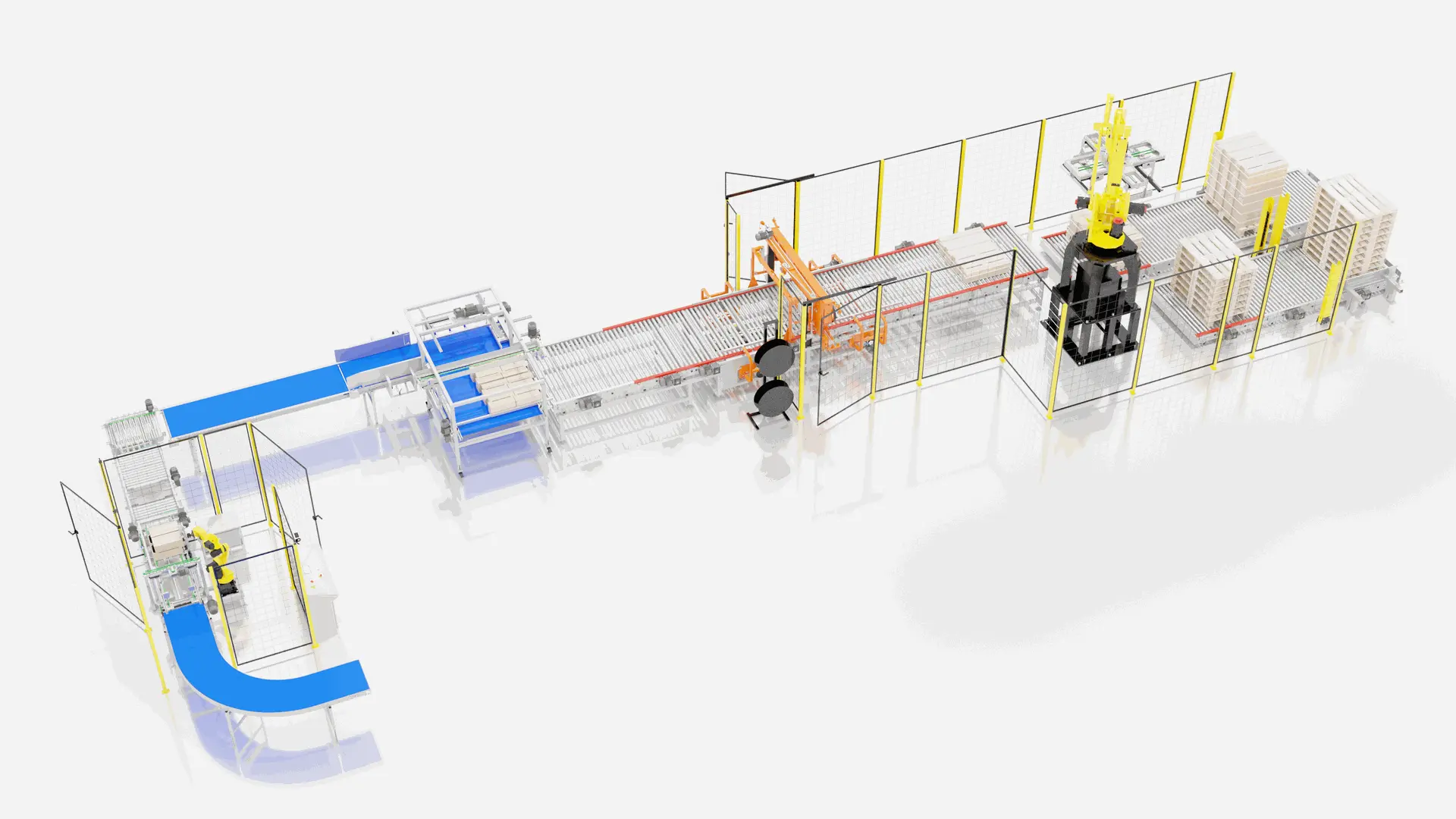

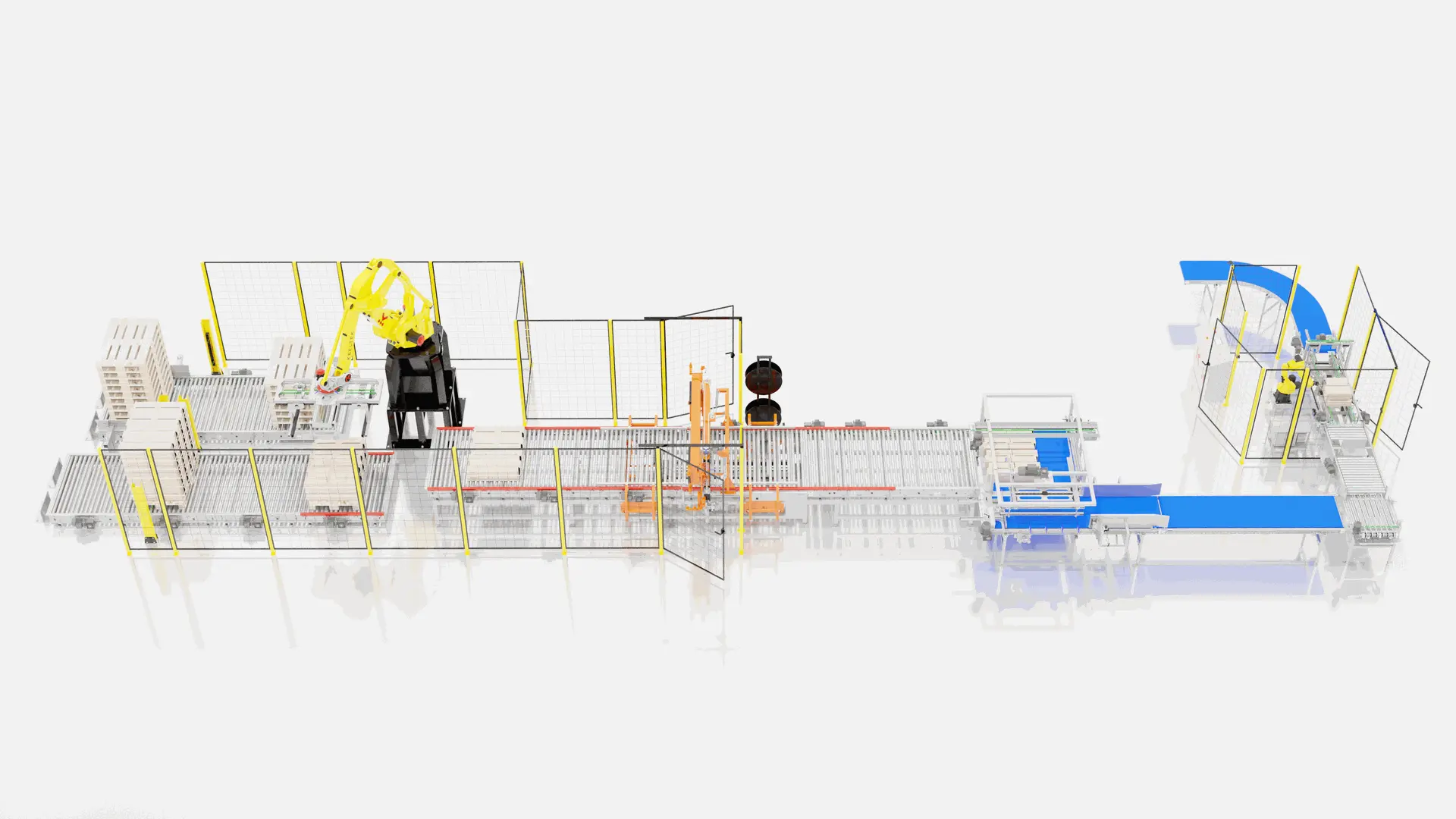

BRIOPACK PLUS

Complete bagging and palletizing line

Complete packaging solution for bags. It includes bag packing by robot, box closing, palletizing, and pallet wrapping. It includes weight control and automatic feeding of empty pallets.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry

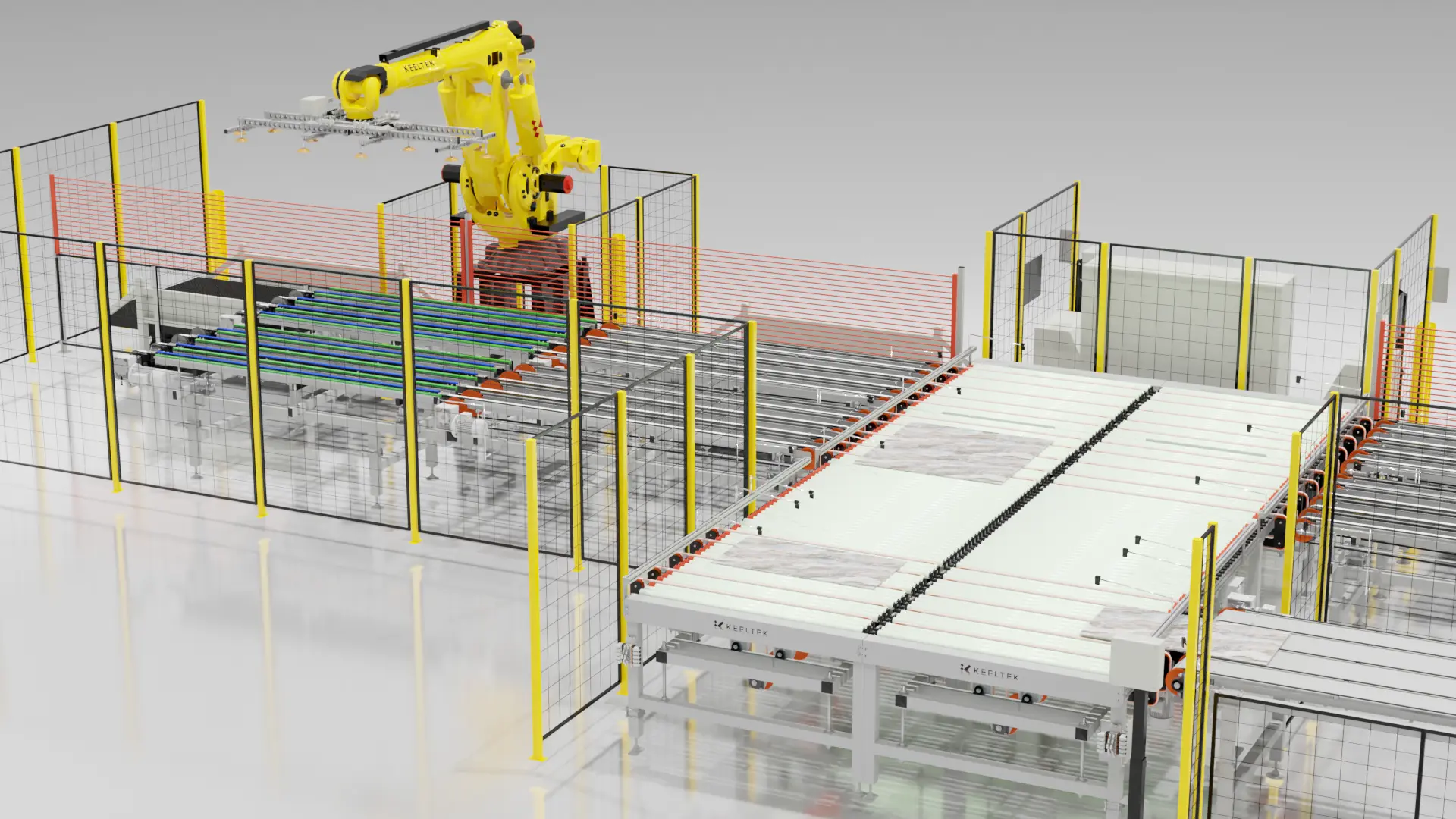

BRIOPACK PLUS

Complete bagging and palletizing line

Complete packaging solution for bags. It includes bag packing by robot, box closing, palletizing, and pallet wrapping. It includes weight control and automatic feeding of empty pallets.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry

BRIOPACK PLUS

Complete bagging and palletizing line

Complete packaging solution for bags. It includes bag packing by robot, box closing, palletizing, and pallet wrapping. It includes weight control and automatic feeding of empty pallets.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry

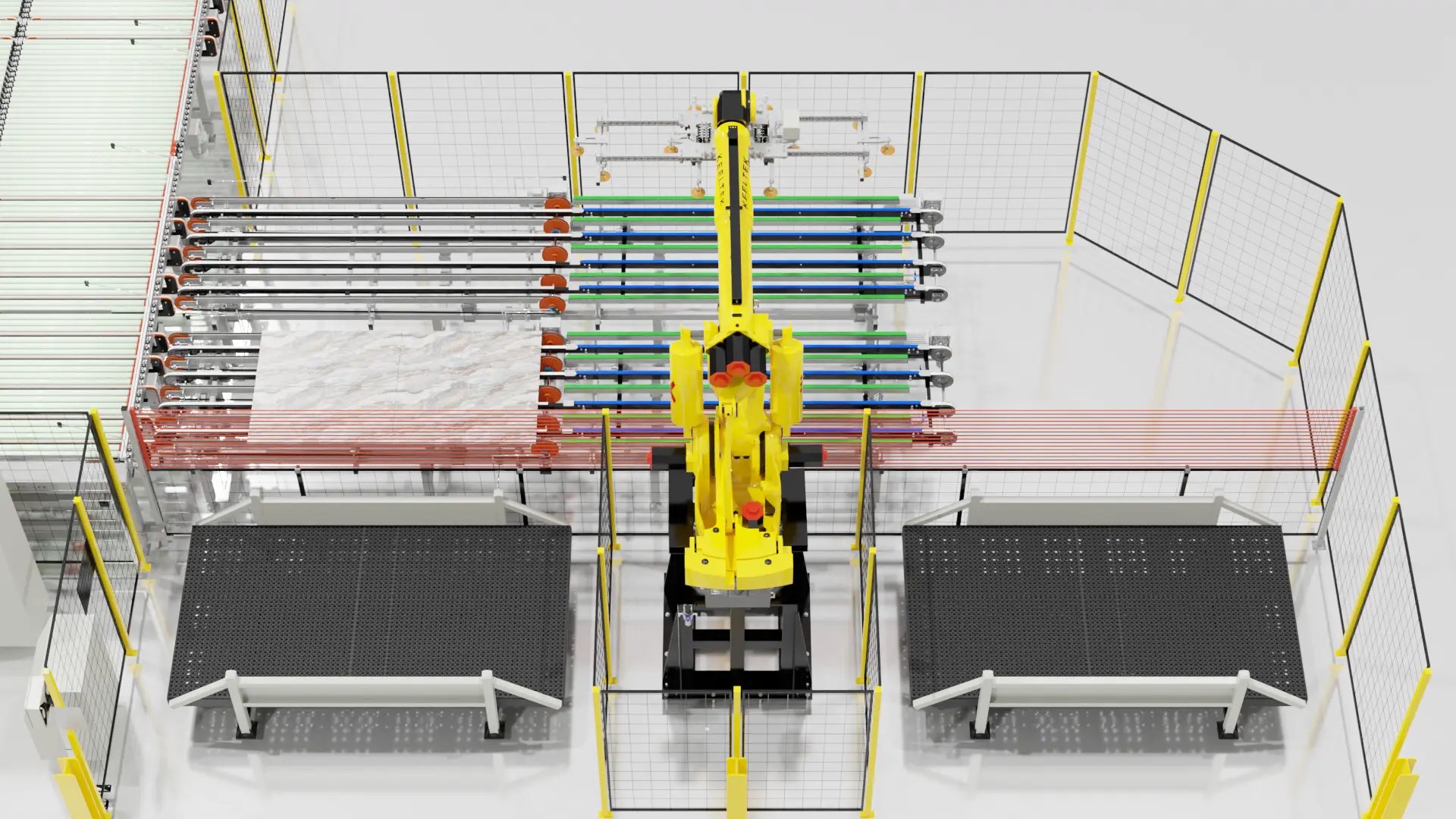

BRIOPACK PLUS

Complete bagging and palletizing line

Complete packaging solution for bags. It includes bag packing by robot, box closing, palletizing, and pallet wrapping. It includes weight control and automatic feeding of empty pallets.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry

BRIOPACK PLUS

Complete bagging and palletizing line

Complete packaging solution for bags. It includes bag packing by robot, box closing, palletizing, and pallet wrapping. It includes weight control and automatic feeding of empty pallets.

Perfect for the following sectors:

Chemical Fruit and vegetable Food and beverages Industry

| Reference product | Bags of any size. |

| Output product |

Strapped pallet of boxes. |

| Maximum cadence | Consult. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Safety and ergonomics:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed by laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Option of baler with or without pallet cover.

- Robot tool with suction plate for greater versatility.

- Quality control by weight with automatic rejection included.

- Adaptable to different sizes of pallets, sacks, boxes.

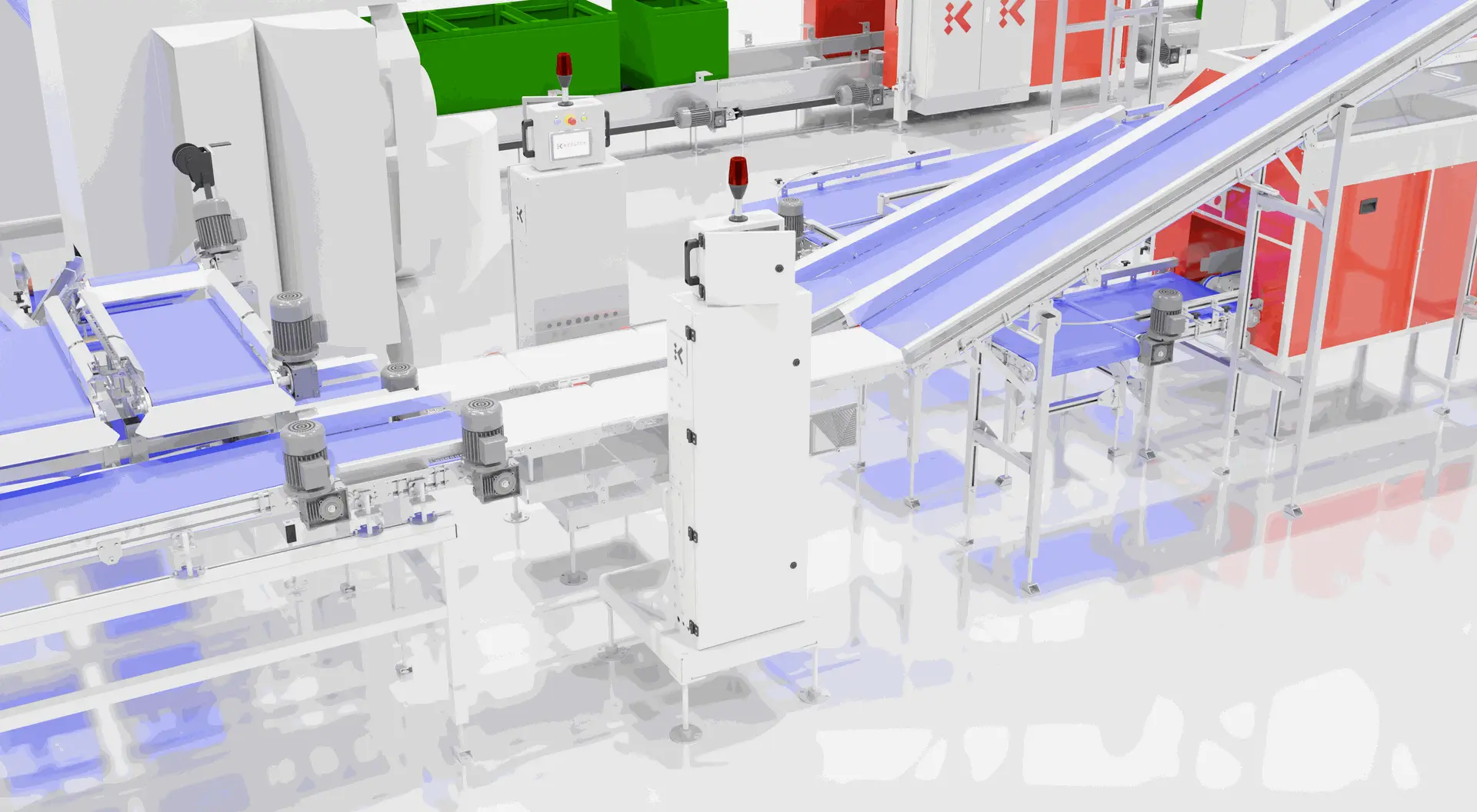

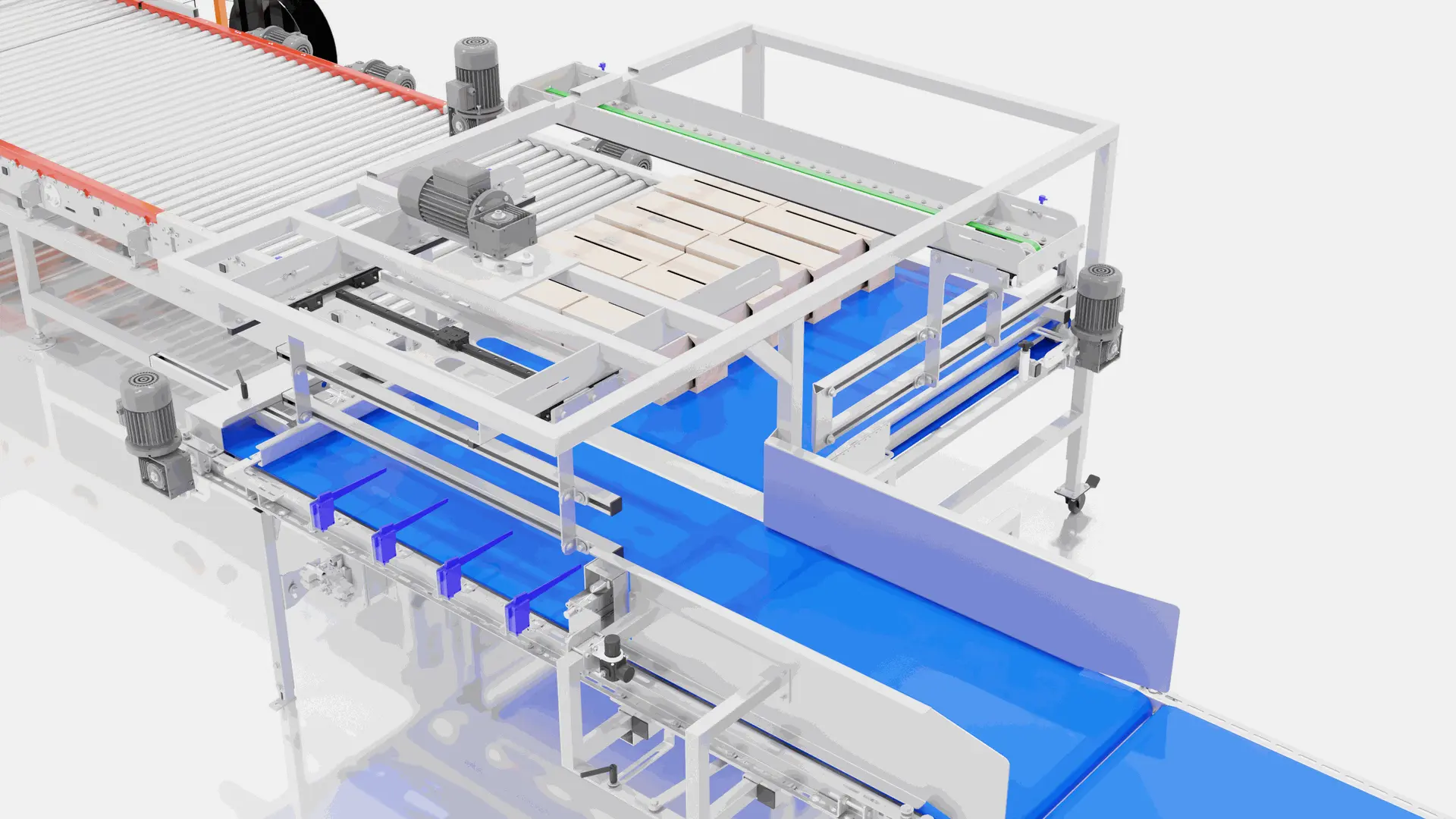

BOXPACKER PLUS

Box palletizing line with volume optimization

Line for matching, mosaic forming, strapping, and automatic palletizing of wooden boxes to optimize shipping volume.

Perfect for the following sectors:

Fruit and vegetable Food and beverages Industry

BOXPACKER PLUS

Box palletizing line with volume optimization

Line for matching, mosaic forming, strapping, and automatic palletizing of wooden boxes to optimize shipping volume.

Perfect for the following sectors:

Fruit and vegetable Food and beverages Industry

BOXPACKER PLUS

Box palletizing line with volume optimization

Line for matching, mosaic forming, strapping, and automatic palletizing of wooden boxes to optimize shipping volume.

Perfect for the following sectors:

Fruit and vegetable Food and beverages Industry

BOXPACKER PLUS

Box palletizing line with volume optimization

Line for matching, mosaic forming, strapping, and automatic palletizing of wooden boxes to optimize shipping volume.

Perfect for the following sectors:

Fruit and vegetable Food and beverages Industry

BOXPACKER PLUS

Box palletizing line with volume optimization

Line for matching, mosaic forming, strapping, and automatic palletizing of wooden boxes to optimize shipping volume.

Perfect for the following sectors:

Fruit and vegetable Food and beverages Industry

BOXPACKER PLUS

Box palletizing line with volume optimization

Line for matching, mosaic forming, strapping, and automatic palletizing of wooden boxes to optimize shipping volume.

Perfect for the following sectors:

Fruit and vegetable Food and beverages Industry

BOXPACKER PLUS

Box palletizing line with volume optimization

Line for matching, mosaic forming, strapping, and automatic palletizing of wooden boxes to optimize shipping volume.

Perfect for the following sectors:

Fruit and vegetable Food and beverages Industry

| Reference product | Adaptable to different box sizes. |

| Cadences | Up to 4,000 boxes per hour. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Features:

- Mosaic generation from user interface

Safety and ergonomics:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed by laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Option to adapt for assembling bundles of 3 boxes according to measurements.

- Option to combine with a table strapping machine for bale design.

Request information instantly

All this without any obligation