Pallet handling solutions

con pallets

Material handling solutions

Pallet-based material handling

solutions

At Keeltek, we offer advanced solutions for automatic pallet storage and destacking systems, optimizing storage and material management at every stage of the industrial process. Our systems are distinguished by their precision, durability, and versatility, allowing them to adapt to a variety of working environments.

Equipped with state-of-the-art technology, Keeltek's automatic storage and destacking systems ensure efficient and continuous pallet handling, reducing downtime, minimizing human error, and maximizing productivity in logistics and production operations.

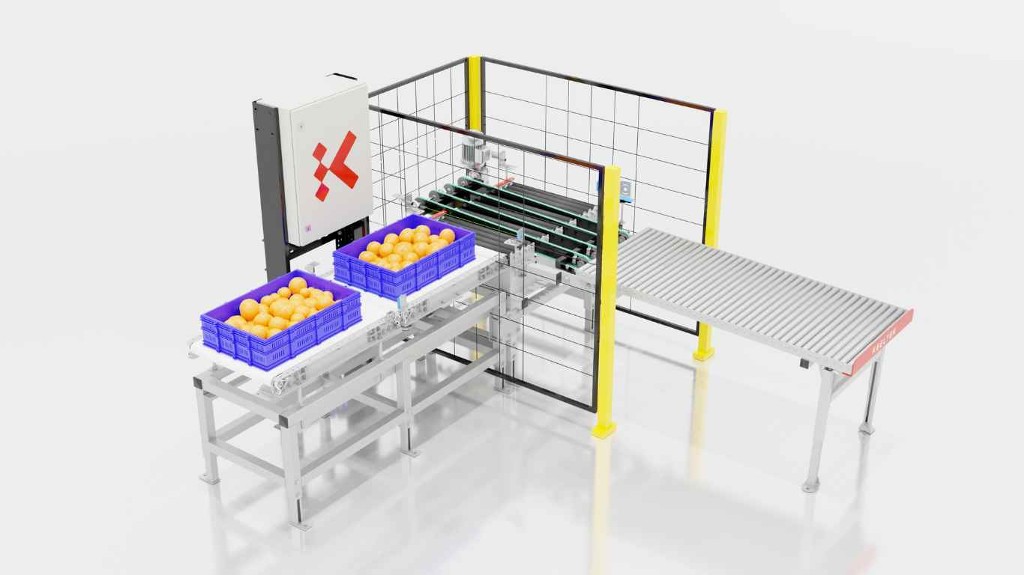

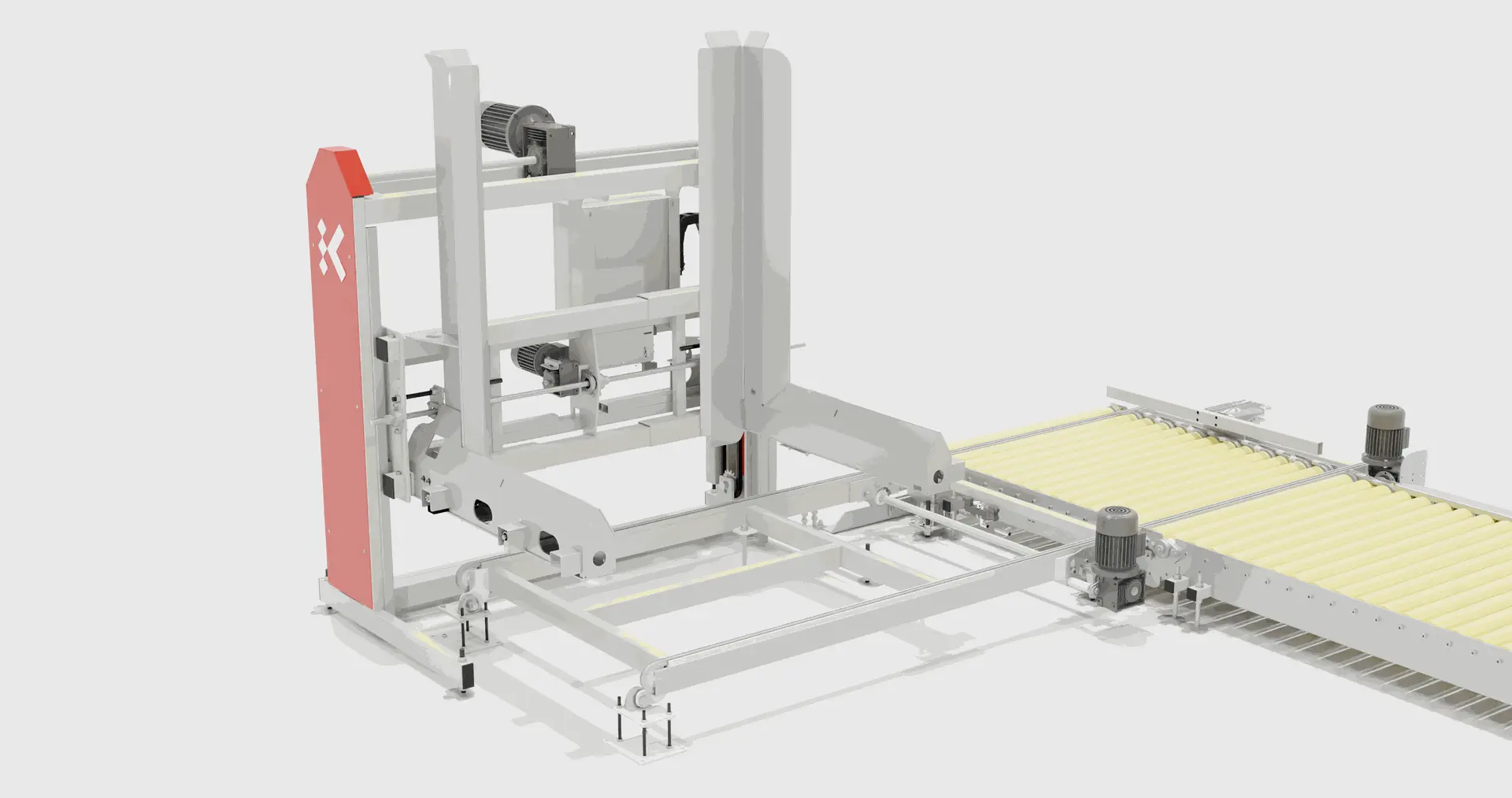

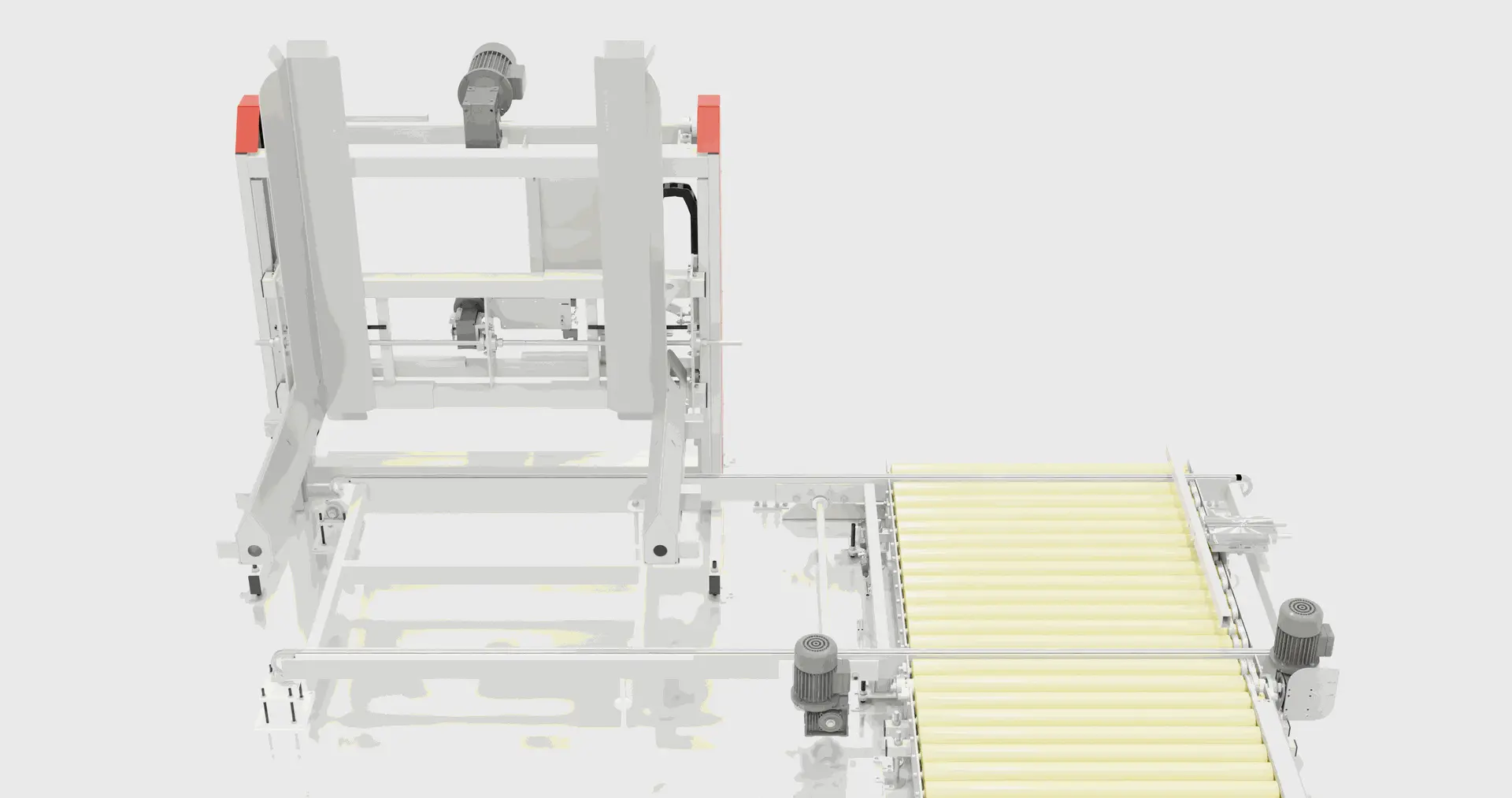

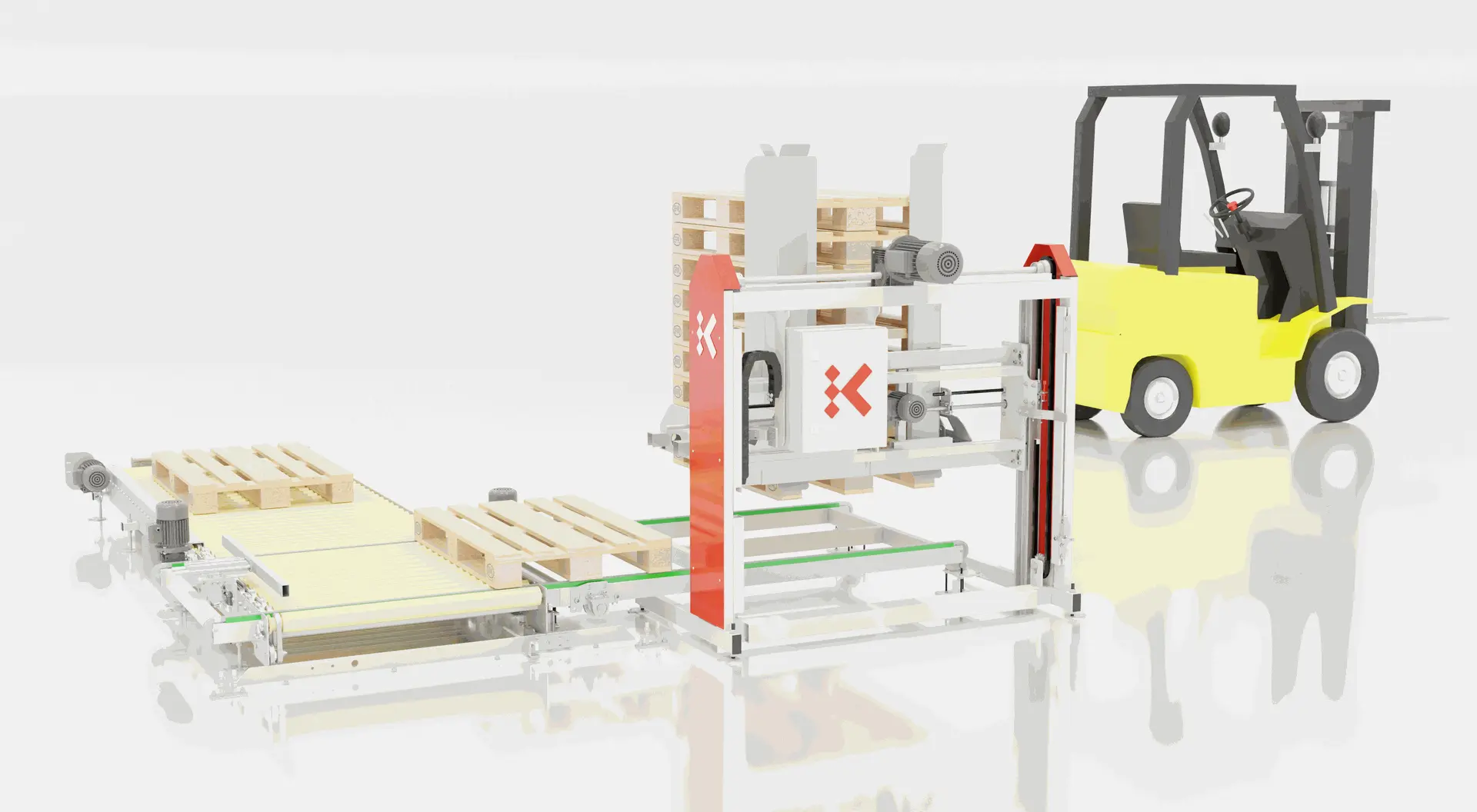

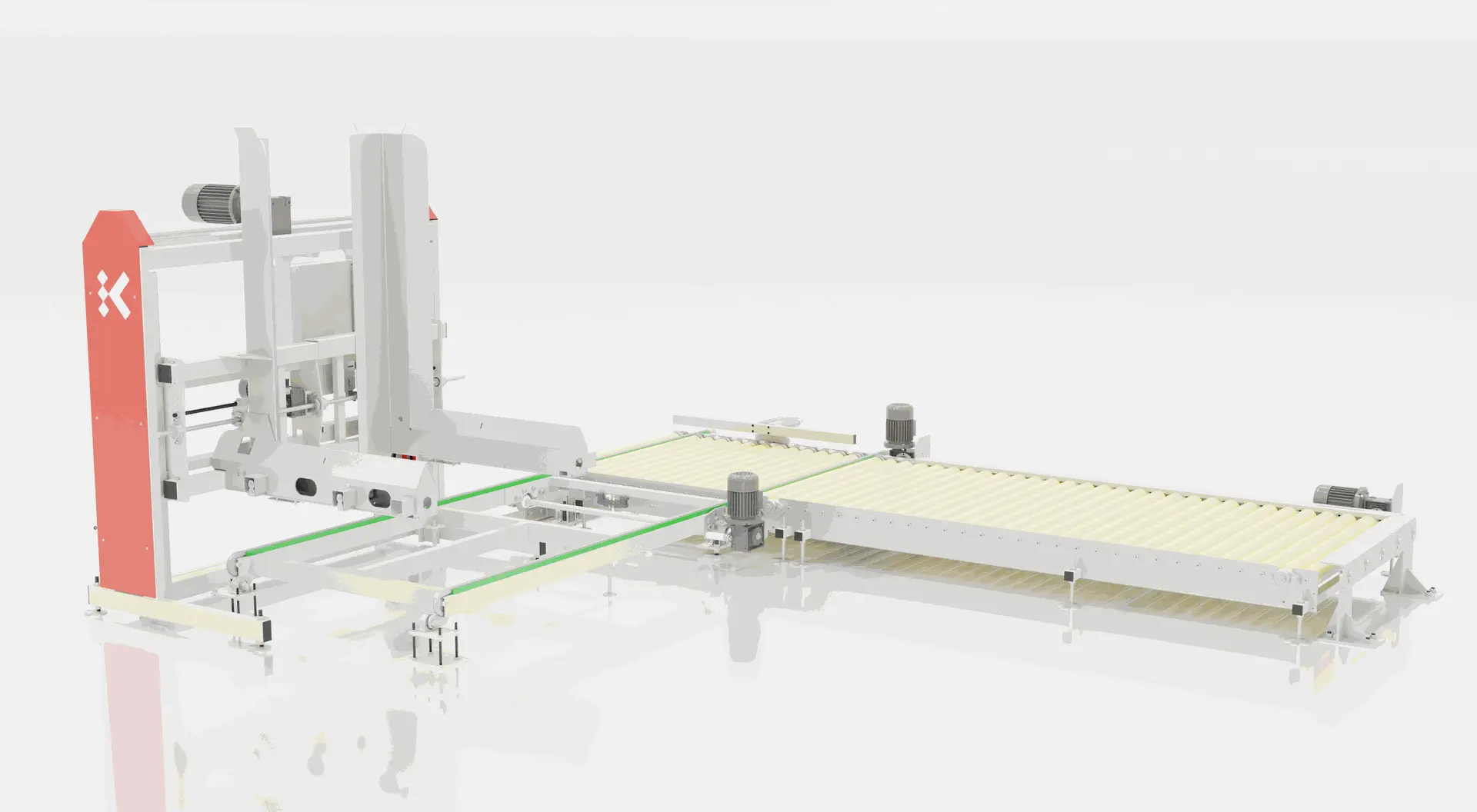

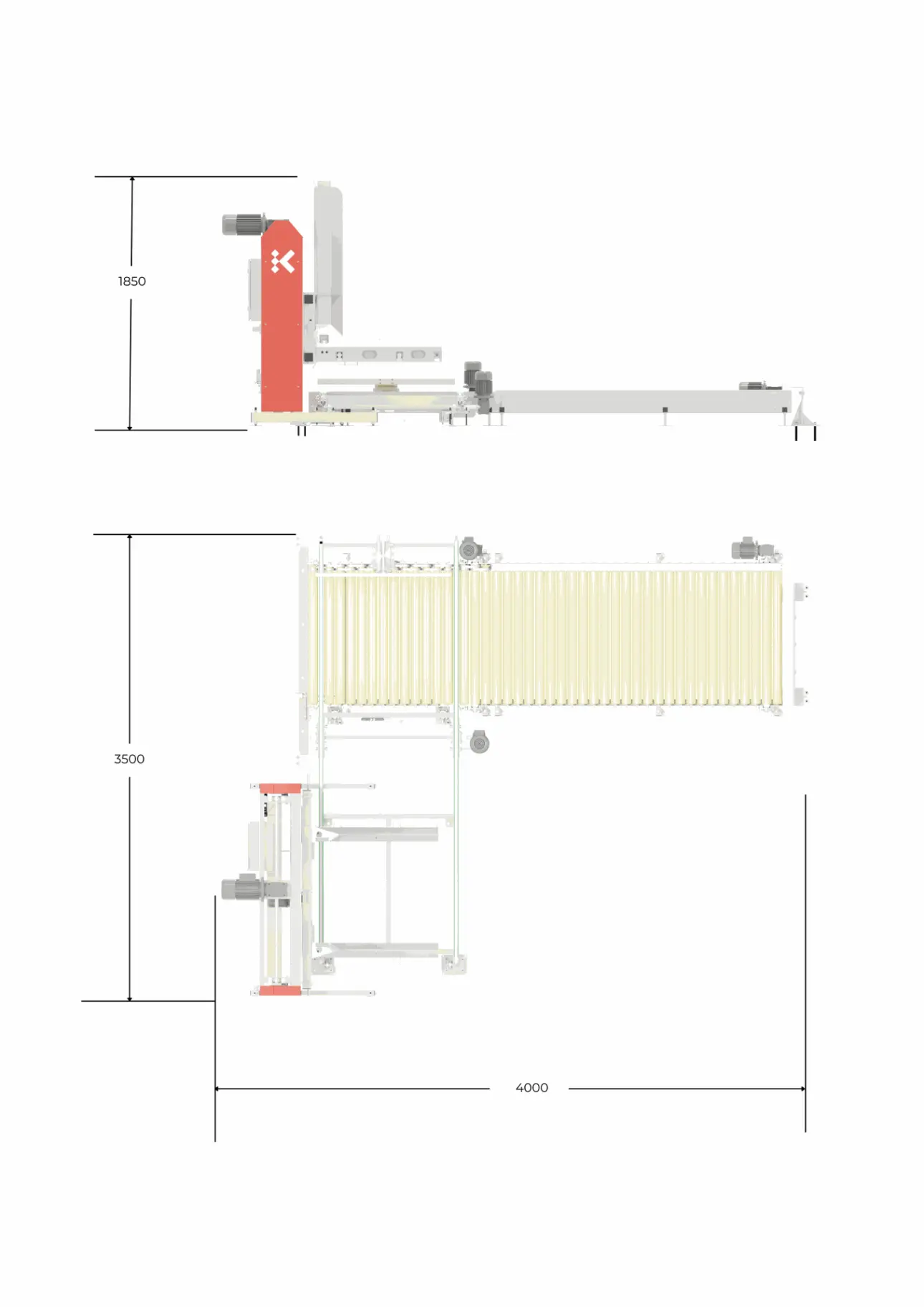

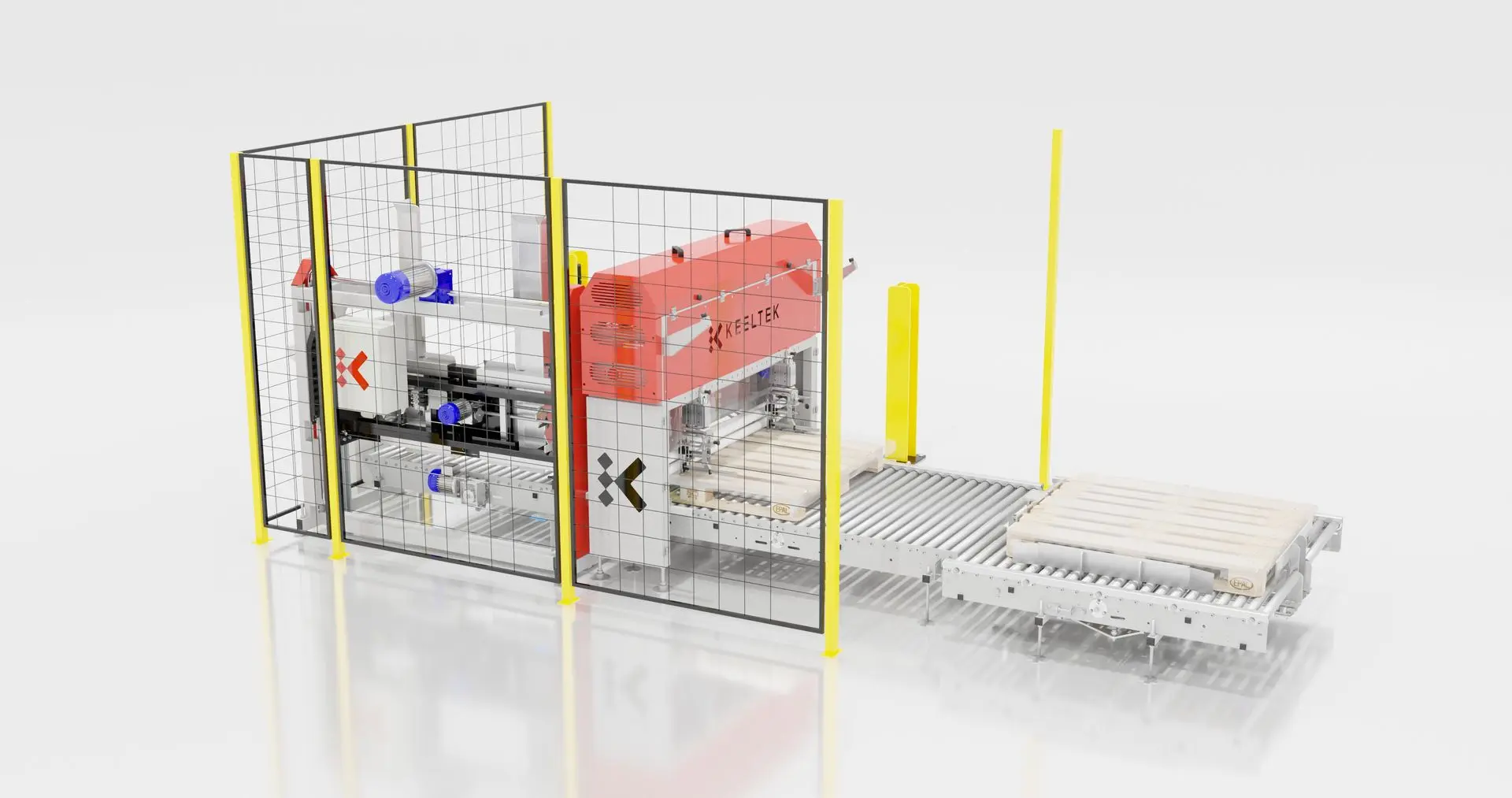

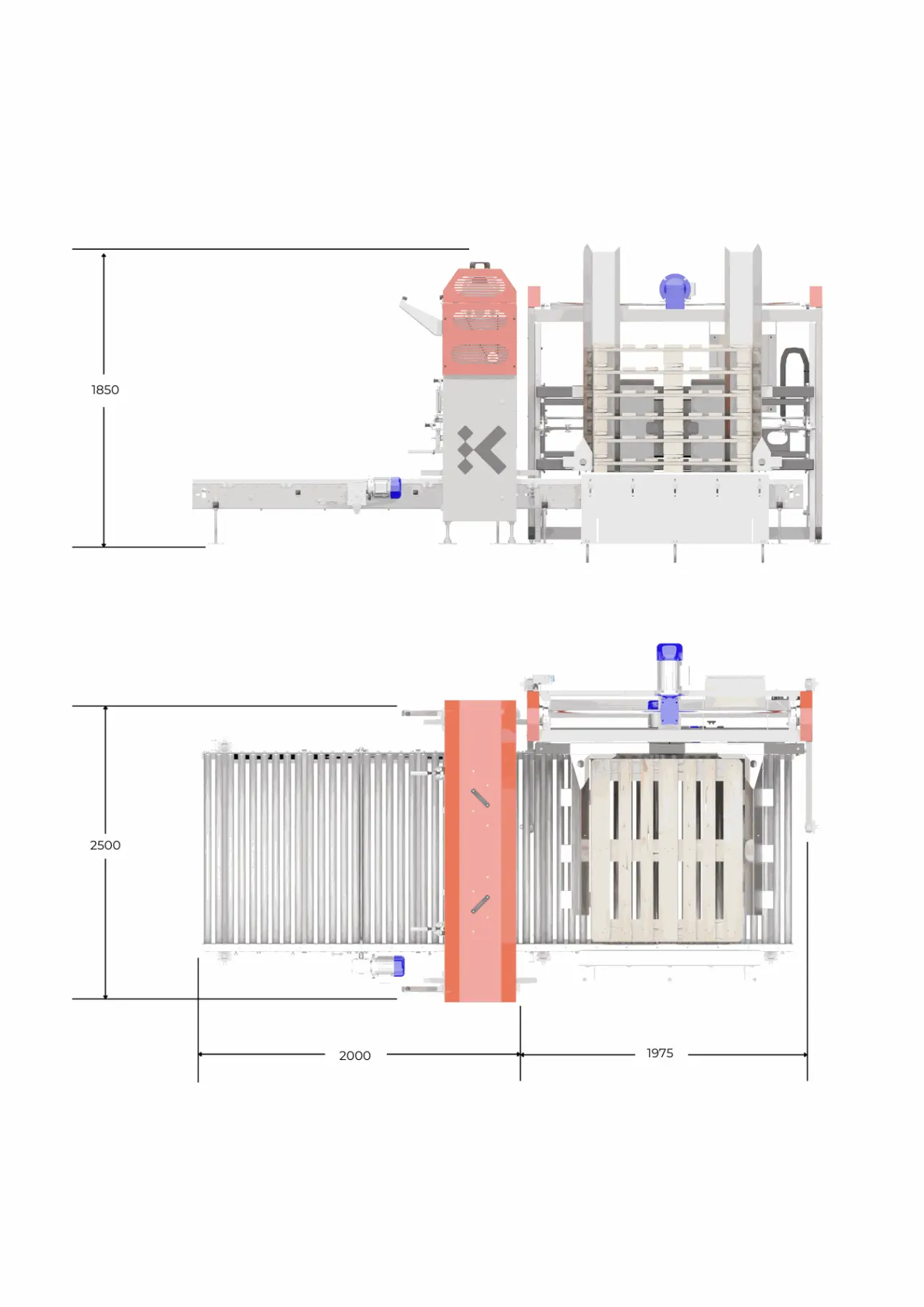

DISPALLET

Automatic pallet destacker

Automatic pallet dispenser for production line. The system is fed by a stack of pallets.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

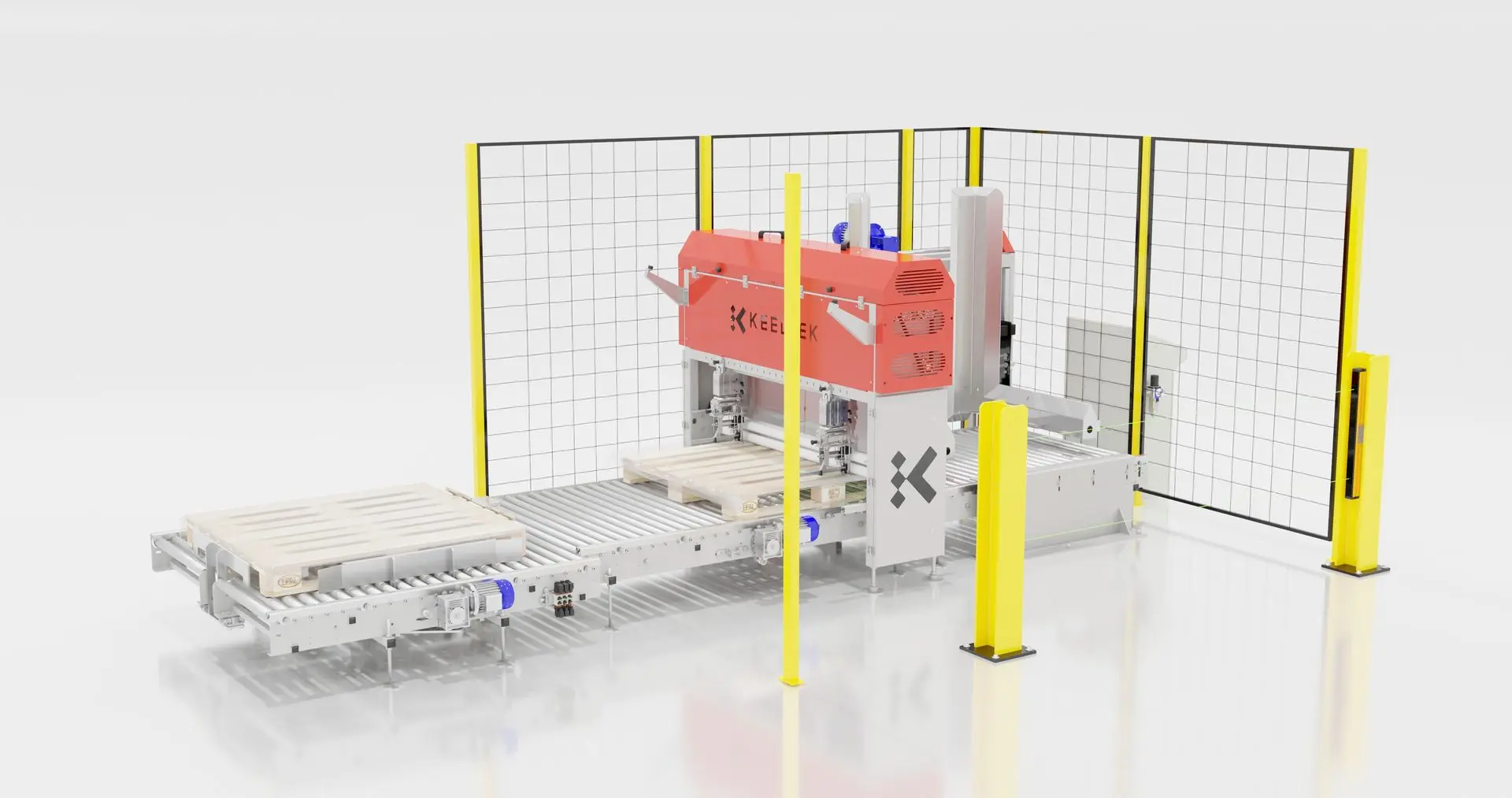

DISPALLET

Automatic pallet destacker

Automatic pallet dispenser for production line. The system is fed by a stack of pallets.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

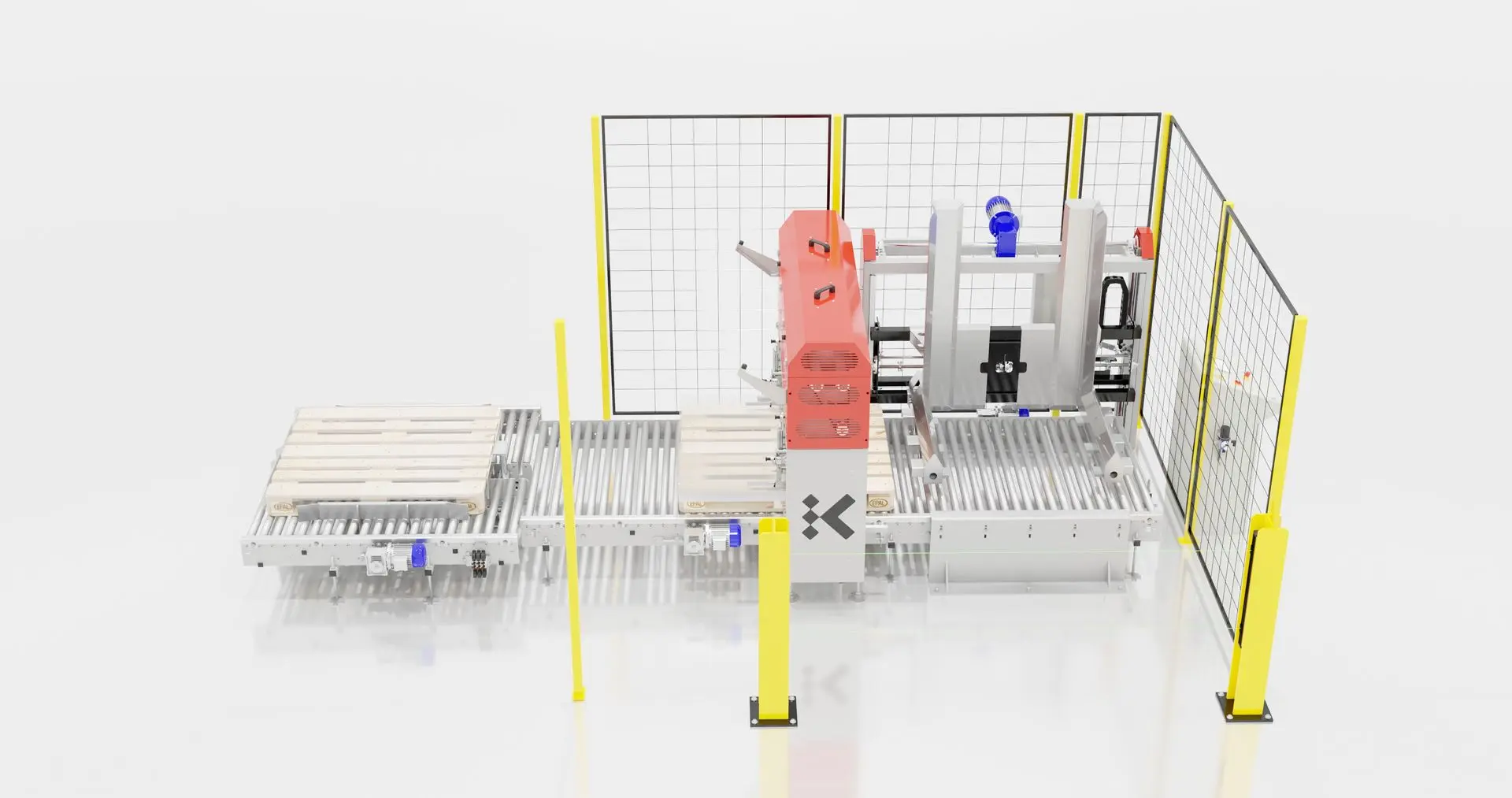

DISPALLET

Automatic pallet destacker

Automatic pallet dispenser for production line. The system is fed by a stack of pallets.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

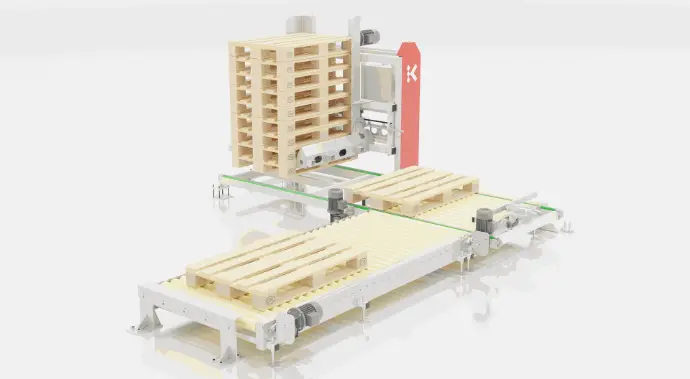

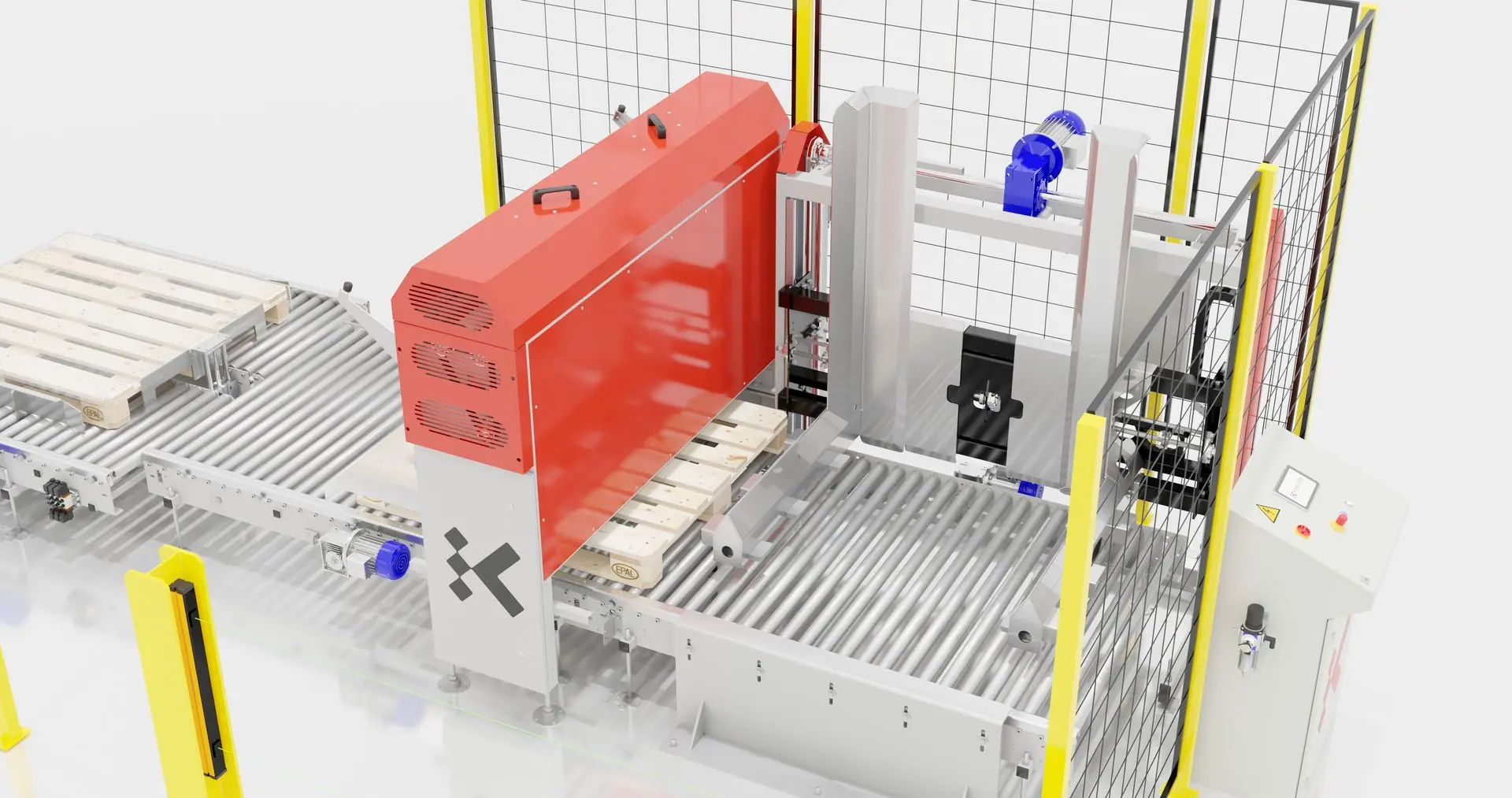

DISPALLET

Automatic pallet destacker

Automatic pallet dispenser for production line. The system is fed by a stack of pallets.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

DISPALLET

Automatic pallet destacker

Automatic pallet dispenser for production line. The system is fed by a stack of pallets.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

DISPALLET

Automatic pallet destacker

Automatic pallet dispenser for production line. The system is fed by a stack of pallets.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

DISPALLET

Automatic pallet destacker

Automatic pallet dispenser for production line. The system is fed by a stack of pallets.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

DISPALLET

Automatic pallet destacker

Automatic pallet dispenser for production line. The system is fed by a stack of pallets.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

| Reference product | Pallets of different sizes (length, width, and height). |

| Compatibility |

Compatible with any palletizing system. |

Storage capacity | Consult. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Safety and ergonomics:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed by laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Automatic adjustment to different pallet widths.

- Delivery to laminator, palletizer, etc.

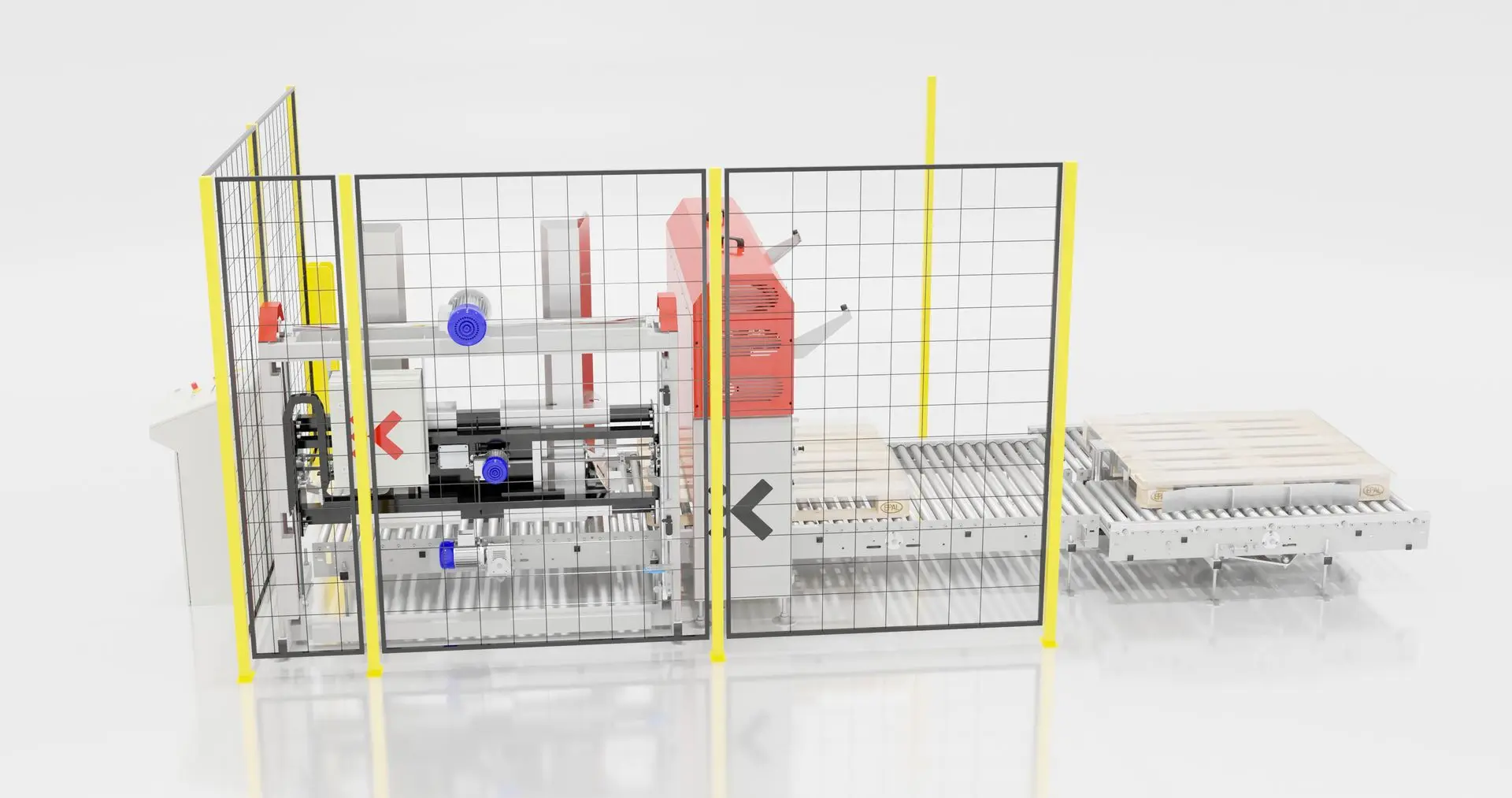

DISPALLET + COVERFILM

Pallet destacker with film cover

Pallet dispenser for line. The system is fed by a stack of pallets. Includes plastic film applicator on the pallet.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

DISPALLET + COVERFILM

Pallet destacker with film cover

Pallet dispenser for line. The system is fed by a stack of pallets. Includes plastic film applicator on the pallet.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

DISPALLET + COVERFILM

Pallet destacker with film cover

Pallet dispenser for line. The system is fed by a stack of pallets. Includes plastic film applicator on the pallet.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

DISPALLET + COVERFILM

Pallet destacker with film cover

Pallet dispenser for line. The system is fed by a stack of pallets. Includes plastic film applicator on the pallet.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

DISPALLET + COVERFILM

Pallet destacker with film cover

Pallet dispenser for line. The system is fed by a stack of pallets. Includes plastic film applicator on the pallet.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

DISPALLET + COVERFILM

Pallet destacker with film cover

Pallet dispenser for line. The system is fed by a stack of pallets. Includes plastic film applicator on the pallet.

Perfect for the following sectors:

Chemical Pharmacy Ceramic Fruit and vegetable Food and beverages Industry

| Reference product | Pallets of different sizes (length, width, and height). |

| Compatibility |

Designed to work in line with DISPALLET. |

|

Integration |

It can be inserted into any existing line on the pallet passage. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Safety and ergonomics:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability:

- Machine manufactured from steel processed by laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

-

Paper or other types of materials supplied in rolls can be applied.

Request information instantly

All this without any obligation