Fitted with compact

machines

Compact machines

Packaging solutions with compact

machines

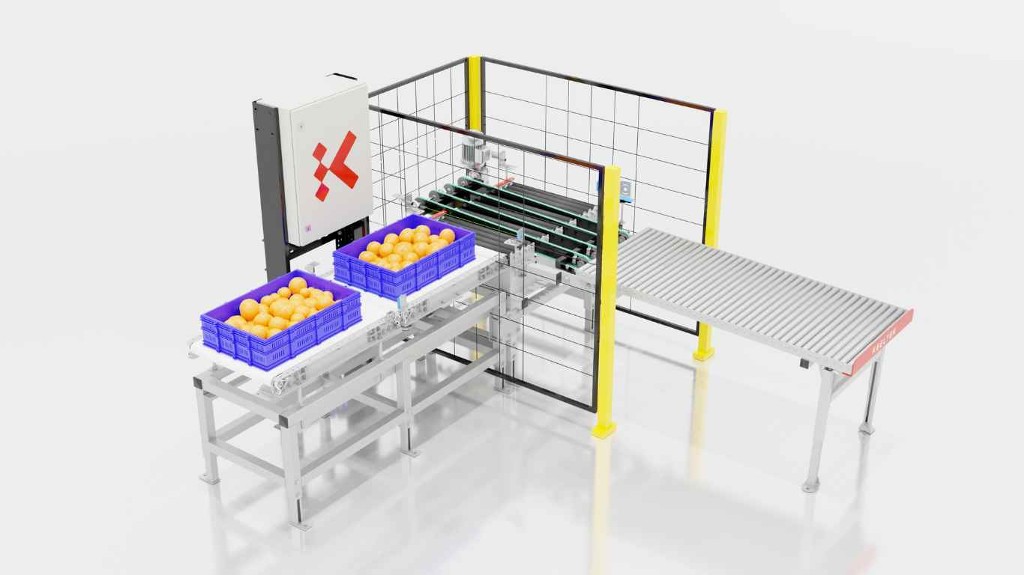

At KEELTEK, we offer a range of compact automatic case packers, developed to optimize space and productivity on your production line, tailored to the specific needs of your company.

BAGPACKER (W25)

Bag packing machine

Machine for packing and counting pre-packaged products in plastic, mesh, and recyclable and compostable paper bags, etc., in boxes weighing up to 30 kg.

Perfect for the following sectors:

Fruit and vegetable Food and beverages Industry Chemical

BAGPACKER (W25)

Bag packing machine

Machine for packing and counting pre-packaged products in plastic, mesh, and recyclable and compostable paper bags, etc., in boxes weighing up to 30 kg.

Perfect for the following sectors:

Fruit and vegetable Food and beverages Industry Chemical

BAGPACKER (W25)

Bag packing machine

Machine for packing and counting pre-packaged products in plastic, mesh, and recyclable and compostable paper bags, etc., in boxes weighing up to 30 kg.

Perfect for the following sectors:

Fruit and vegetable Food and beverages Industry Chemical

BAGPACKER (W25)

Bag packing machine

Machine for packing and counting pre-packaged products in plastic, mesh, and recyclable and compostable paper bags, etc., in boxes weighing up to 30 kg.

Perfect for the following sectors:

Fruit and vegetable Food and beverages Industry Chemical

BAGPACKER (W25)

Bag packing machine

Machine for packing and counting pre-packaged products in plastic, mesh, and recyclable and compostable paper bags, etc., in boxes weighing up to 30 kg.

Perfect for the following sectors:

Fruit and vegetable Food and beverages Industry Chemical

BAGPACKER (W25)

Bag packing machine

Machine for packing and counting pre-packaged products in plastic, mesh, and recyclable and compostable paper bags, etc., in boxes weighing up to 30 kg.

Perfect for the following sectors:

Fruit and vegetable Food and beverages Industry Chemical

Configurable box and product entry direction

| Reference product | Boxes measuring 600 mm x 400 mm – Bags up to 5 kg |

| Carga máxima admisible | Up to 50 kg |

|

Connectivity

|

LAN |

| Cadences | Up to 90 units per minute. |

- Conveyor circuit for upstream product management.

- Automatic box dispenser.

- Stacking or palletizing full boxes.

- Kit for accommodating boxes measuring 400 mm x 300 mm.

- KTS, remote assistance.

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Features:

- Simple and intuitive creation of mosaics by the operator using proprietary software.

- Reversed layer function for improved stability.

Safety and ergonomics:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability

- Machine manufactured from steel processed by laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

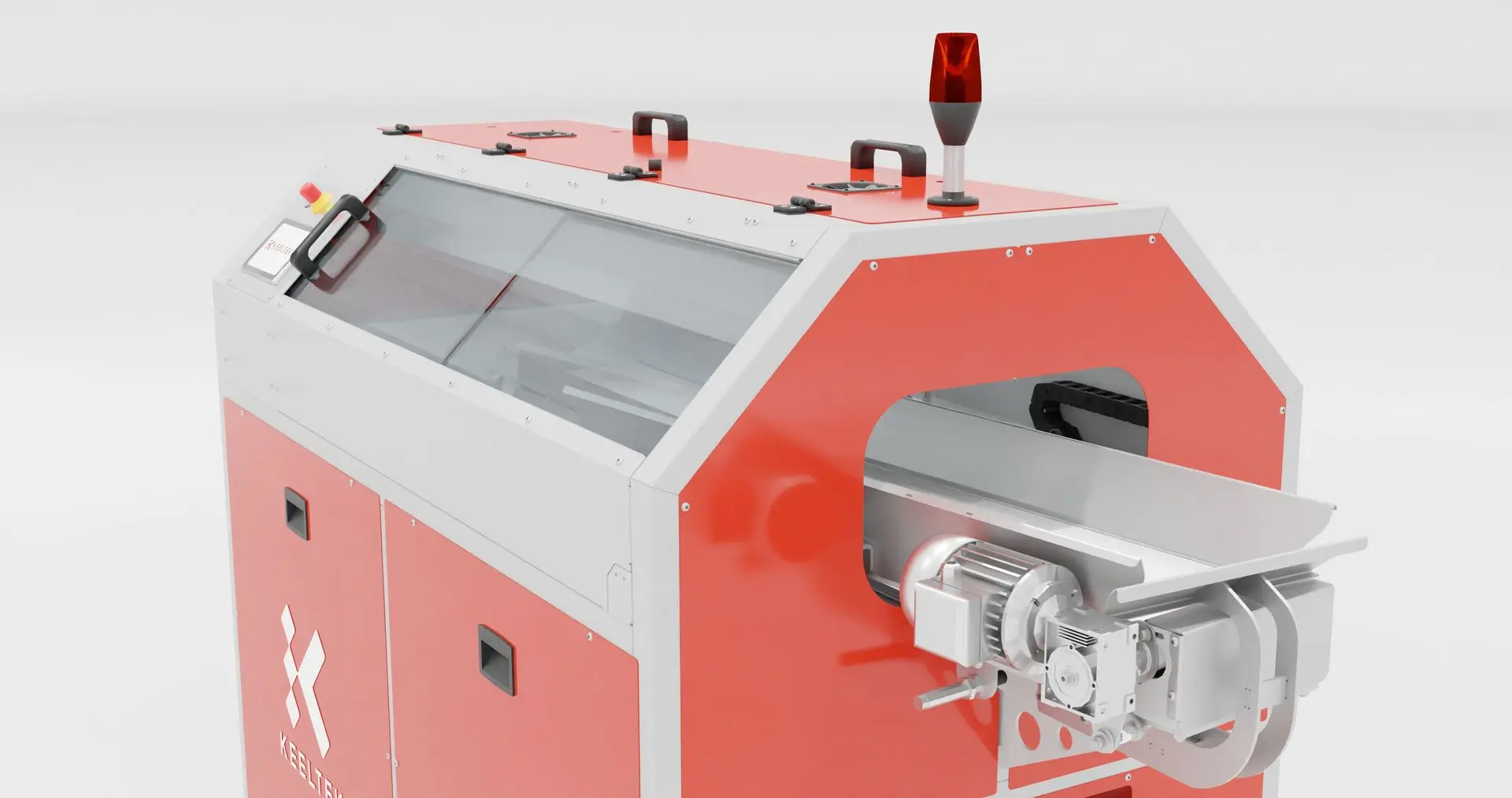

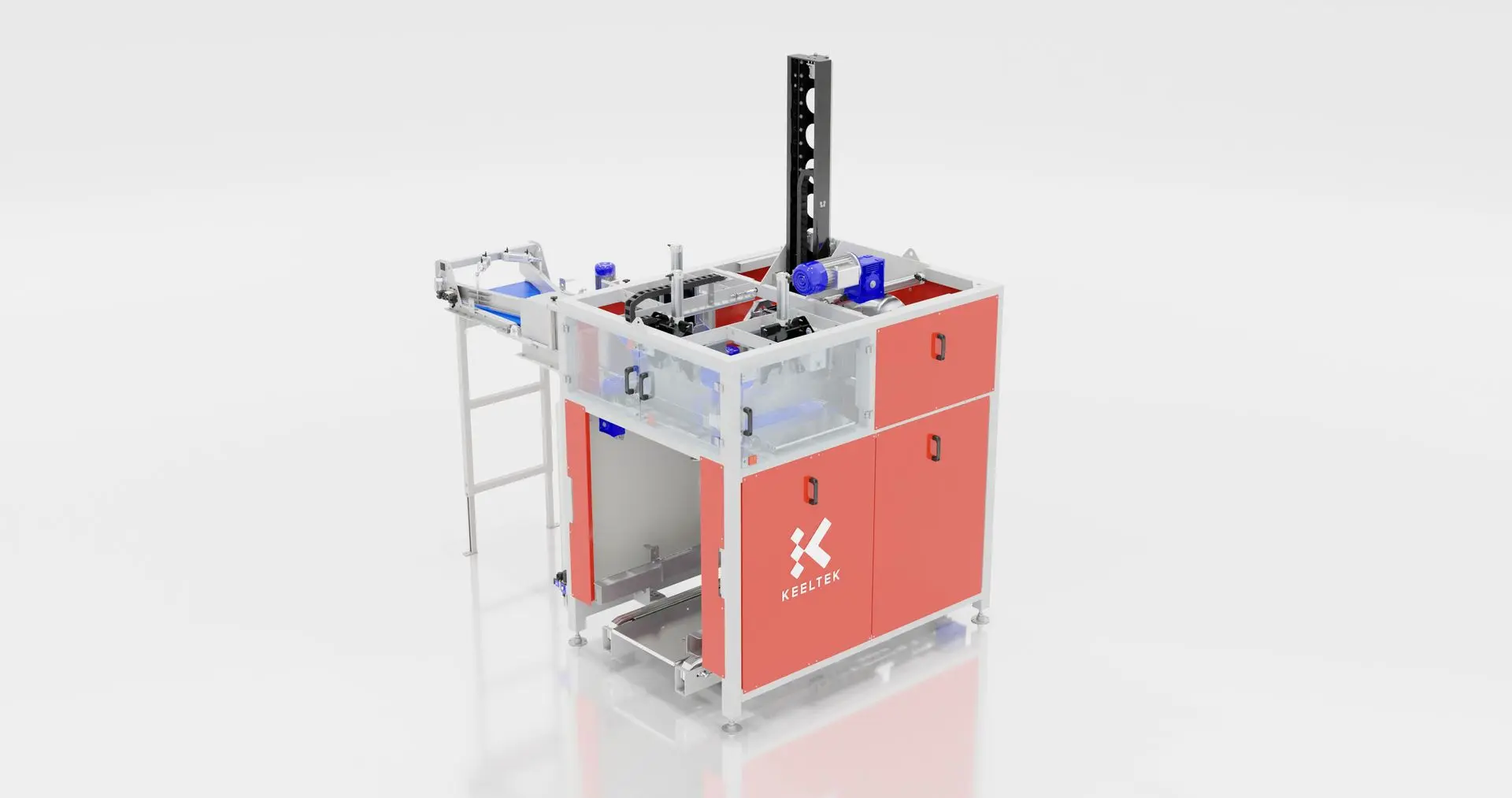

BAGPACKER W250

Bag-into-box packing machine

Machine for packing and counting pre-packaged products in plastic, mesh, and recyclable and compostable paper bags, etc., in boxes weighing up to 250 kg.

Perfect for the following sectors:

Fruit and vegetable Food and beverages Industry Chemical

BAGPACKER W250

Bag-into-box packing machine

Machine for packing and counting pre-packaged products in plastic, mesh, and recyclable and compostable paper bags, etc., in boxes weighing up to 250 kg.

Perfect for the following sectors:

Fruit and vegetable Food and beverages Industry Chemical

BAGPACKER W250

Bag-into-box packing machine

Machine for packing and counting pre-packaged products in plastic, mesh, and recyclable and compostable paper bags, etc., in boxes weighing up to 250 kg.

Perfect for the following sectors:

Fruit and vegetable Food and beverages Industry Chemical

BAGPACKER W250

Bag-into-box packing machine

Machine for packing and counting pre-packaged products in plastic, mesh, and recyclable and compostable paper bags, etc., in boxes weighing up to 250 kg.

Perfect for the following sectors:

Fruit and vegetable Food and beverages Industry Chemical

BAGPACKER W250

Bag-into-box packing machine

Machine for packing and counting pre-packaged products in plastic, mesh, and recyclable and compostable paper bags, etc., in boxes weighing up to 250 kg.

Perfect for the following sectors:

Fruit and vegetable Food and beverages Industry Chemical

| Reference product | Boxes measuring 800 mm x 600 mm – Bags up to 10 kg |

|

Connectivity

|

LAN |

| Cadences | up to 60 units per minute. |

Efficiency:

- Low consumption, IEE (Intelligent Energy Efficiency).

- The motorized elements remain at rest until they need to move product and, in turn, stop if they do not receive product after a certain period of time.

Features:

- Simple and intuitive creation of mosaics by the operator using proprietary software.

- Reversed layer function for improved stability.

Safety and ergonomics:

- Study and treatment of safety and ergonomics from the start of the design process, machine subjected to risk analysis and auditable risk assessment.

- Touchscreen interface with various levels of accessibility, allowing you to adjust all parameters that influence the machine's performance. (Recipes, Timers, Speeds, Counters, etc.)

Durability

- Machine manufactured from steel processed by laser cutting, water jet cutting, bending, electro-welding, and precision parts made in machining centers.

- Structures and thicknesses optimized using specialized software calculations.

- Combined finishes in two-component polyurethane, epoxy paint, galvanized and/or stainless steel.

- Conveyor circuit for upstream product management.

- Folding and sealing of boxes. (FOLDBOX)

- Strapping and stacking the boxes.

- KTS, remote assistance.

Request information instantly

All this without any obligation